When it comes to maintaining and repairing machinery, understanding the layout and functions of each component is essential. With a clear visual representation, identifying parts becomes much easier, ensuring that repairs are done quickly and accurately. This is crucial for those looking to extend the lifespan of their equipment and avoid unnecessary downtime.

By referencing detailed illustrations of your machine’s structure, you can pinpoint the exact location of each piece and learn about its specific role. These resources help users navigate through complex assemblies, making maintenance tasks simpler and more efficient.

Knowing how to interpret these guides is a key skill for anyone working with mechanical equipment. Whether you’re a seasoned technician or a DIY enthusiast, these visual aids can greatly enhance your ability to perform routine checks and fix issues as they arise.

Understanding the Equipment Layout

To effectively maintain and repair your machinery, it is essential to have a clear understanding of its internal structure. A visual reference that showcases the various components and their placement allows for a more efficient approach to troubleshooting and repairs. Knowing where each piece fits within the system can save time and ensure that every task is completed accurately.

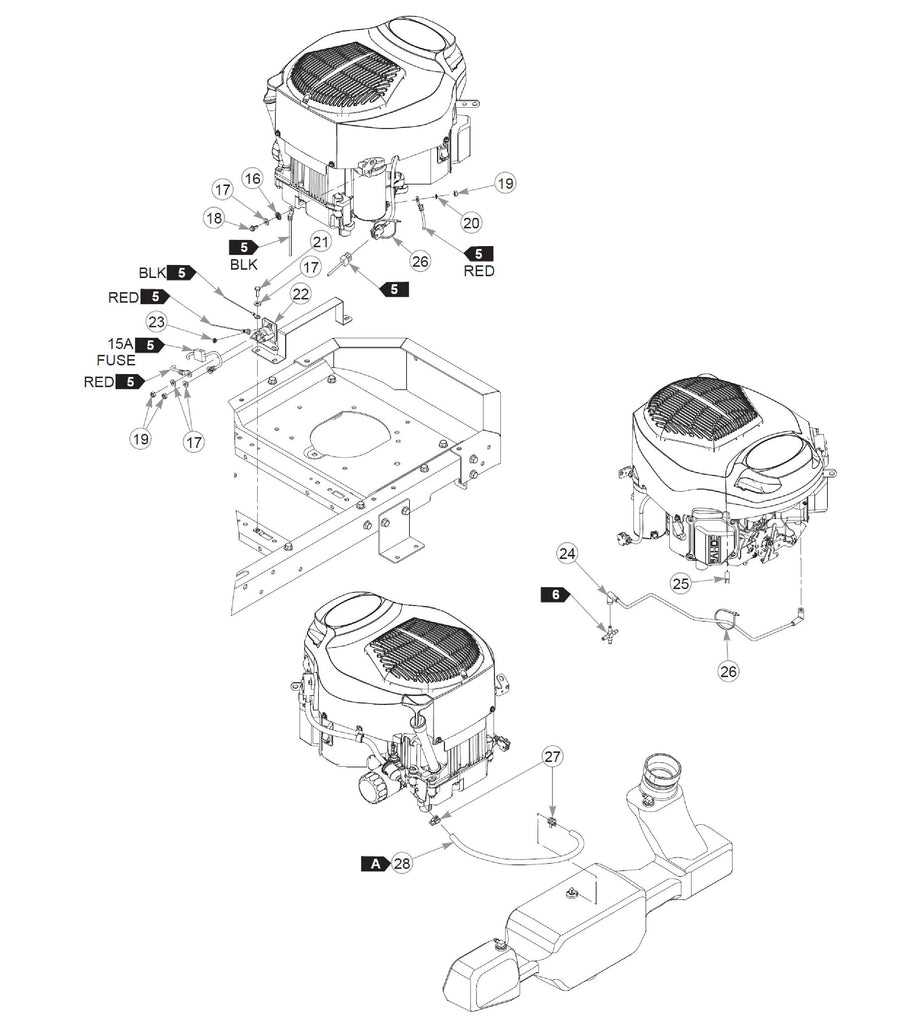

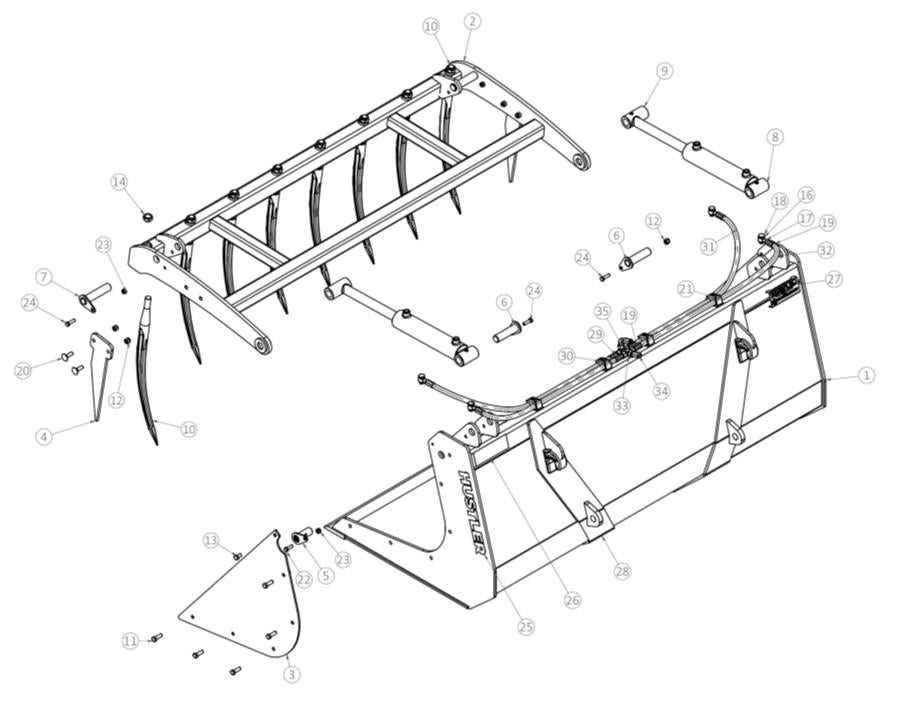

How to Read the Visual Representation

Learning to interpret these schematics is a critical skill. Each component is typically labeled with unique identifiers, which makes it easy to locate specific items during maintenance. These guides often include arrows or numbered sections that indicate connections and the flow of energy, helping users quickly pinpoint potential issues.

The Importance of Accurate Identification

Accurate identification of the machinery’s components helps prevent mistakes during repairs. By knowing exactly what each part does and where it is located, you can avoid unnecessary disassembly and focus on the area that needs attention. This approach increases efficiency and reduces the likelihood of damaging other components.

How to Use Equipment Layout Effectively

To get the most out of your maintenance efforts, it’s crucial to understand how to utilize the visual guides that depict the structure of your machinery. These resources can be invaluable when identifying malfunctioning components, organizing repairs, or performing routine checks. When used properly, they allow you to troubleshoot efficiently, saving both time and effort.

The key to effective usage lies in understanding the labels and annotations included in the illustration. Look for identifiers that correspond to the specific elements of your equipment. Once you know which parts need attention, follow the visual flow to understand how each piece interacts with the others. This ensures that you address issues in the right sequence and prevent unnecessary disassembly.

Additionally, make sure to refer to these guides regularly during maintenance routines. Familiarity with the layout can greatly improve your ability to spot issues early and manage repairs without the need for constant rechecking. Over time, this knowledge will streamline your workflow and enhance the overall performance of the equipment.

Common Equipment Components and Their Functions

Every machine consists of various components, each serving a specific role to ensure proper operation. Understanding the function of each element is essential for performing effective repairs and maintenance. Recognizing how individual parts contribute to the overall system helps identify issues more efficiently and ensures that repairs are focused where they are most needed.

One of the most crucial elements is the engine, which powers the entire system. It drives the machinery and allows other components to function. Alongside the engine, the transmission system plays a vital role in transferring energy, ensuring smooth operation across various speeds and settings.

Another important piece is the drive belt, responsible for transmitting power from the engine to other parts of the machine. This component requires regular inspection, as wear and tear can lead to significant performance issues. Additionally, the hydraulic system is responsible for providing power to critical functions such as steering and lifting, making it a key area for maintenance attention.