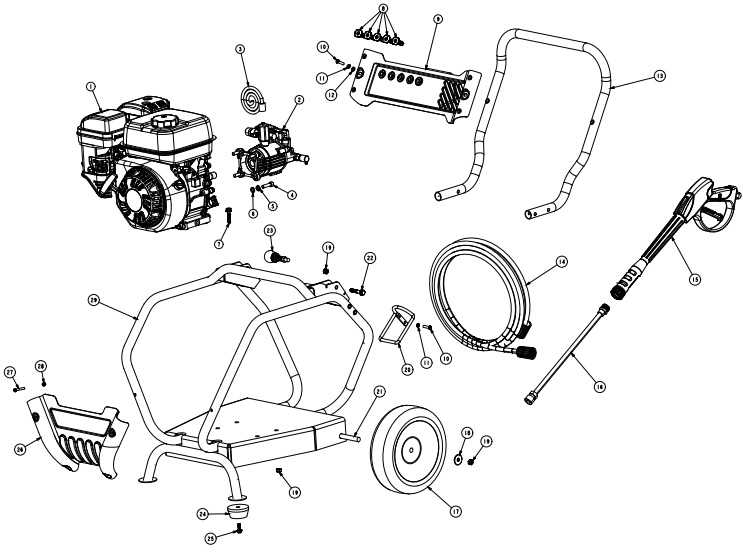

Every cleaning device consists of various essential elements that work together to ensure optimal performance. Identifying these components is crucial for effective maintenance and troubleshooting. By understanding how each piece functions, users can easily recognize issues and replace damaged or worn-out parts. This knowledge also helps in proper care, ensuring the longevity of the machine.

How to Interpret the Layout of Your Cleaning System

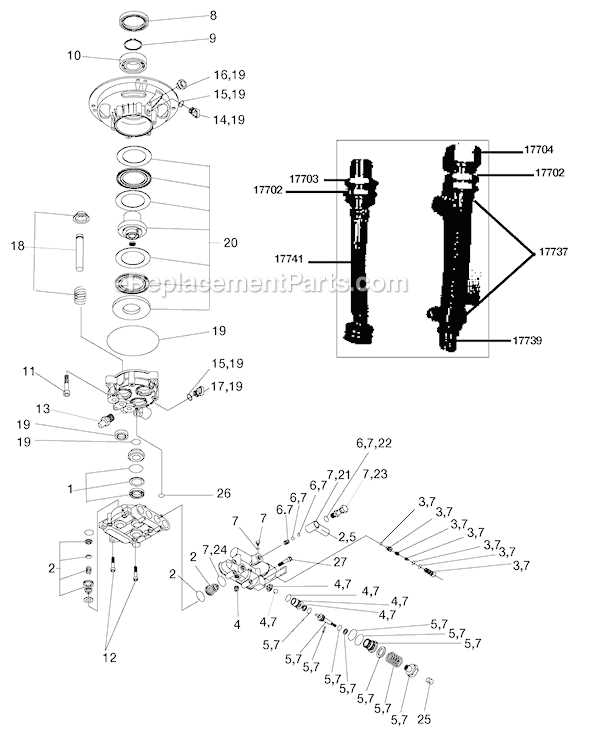

To properly maintain and repair your equipment, it’s vital to understand the layout of the internal system. Each component is usually represented in a detailed guide that highlights its position and function. This can assist in recognizing the relationship between parts and understanding how they work together to achieve the desired result.

Common Elements Found in Cleaning Devices

- Motor: Powers the system, enabling movement and operation.

- Hose Connections: Ensure the flow of liquid or air for efficient use.

- Trigger Mechanism: Controls the release of the cleaning solution or air pressure.

- Water Inlet: The entry point for the liquid used in cleaning tasks.

Typical Problems and Solutions

Devices often experience issues due to wear and tear or misuse. Common problems include low performance, leaks, or blockages. These issues are typically easy to identify once the system’s structure is understood. Regular maintenance and proper care can help prevent these problems from becoming major concerns.

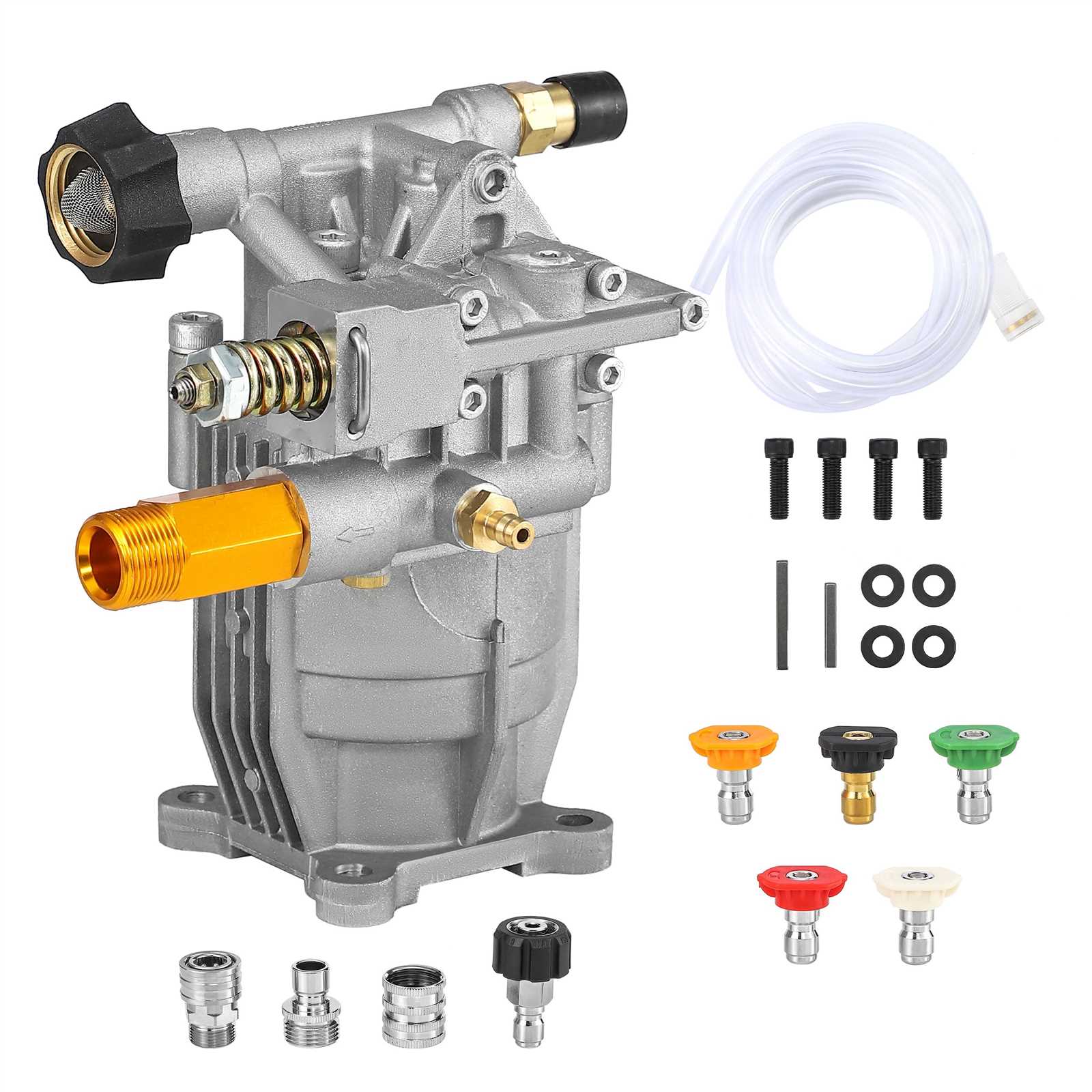

Replacing Worn-Out or Damaged Parts

When a component shows signs of failure, timely replacement is essential. Refer to the system guide to find the correct part number and installation instructions. Using the correct replacement ensures the machine continues to operate efficiently and safely.

Understanding the Components of Your Cleaning Device

Proper maintenance and efficient performance of your equipment depend on knowing its structure and how the different elements interact. By familiarizing yourself with the essential components, you can ensure longevity, better functionality, and ease in fixing any problems that arise. Identifying which part of the system needs attention helps in performing repairs quickly and accurately.

How to Read a Device Layout

A clear understanding of the system’s layout allows for easier troubleshooting and maintenance. The layout often provides a detailed visual guide, indicating the position and function of each component. Knowing how each piece works in relation to the others is crucial when repairing or replacing parts.

Common Issues with Cleaning Equipment

Regular use may lead to issues like clogs, low performance, or leaks. Identifying these problems early allows for swift resolution. Typical issues often involve faulty connections, blocked inlets, or worn-out seals, which can hinder the overall performance of the device. Understanding the layout helps pinpoint where the issue originates.

Timely replacement of any malfunctioning components is essential. Following the visual guide ensures that replacements are done correctly, restoring the equipment’s performance. Regular care and maintenance will prolong the device’s life and improve its efficiency.