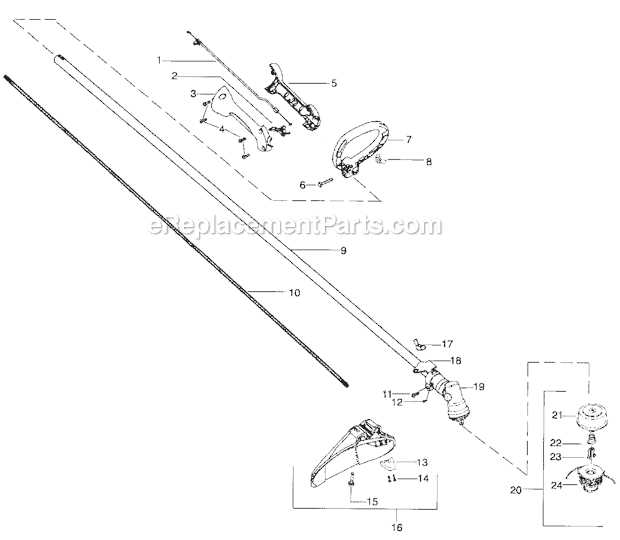

When it comes to keeping your outdoor tools running smoothly, knowing how each component fits together is crucial. A clear understanding of your equipment’s internal structure can make maintenance and repair tasks much easier, ensuring longer-lasting performance. By familiarizing yourself with the various elements that contribute to the functionality of these devices, you can avoid unnecessary repairs and maximize their efficiency.

Proper maintenance is essential to prevent wear and tear. Regular checks on the internal mechanisms, as well as the external parts, can identify early signs of damage or malfunction. Whether you’re dealing with minor repairs or larger fixes, having a visual guide of how the pieces interact with each other can save time and effort.

Accurate identification of each part helps in understanding their role, making troubleshooting more straightforward. This knowledge not only aids in repairs but also ensures that the right replacement parts are used, keeping everything functioning as it should.

Craftsman 25cc Weed Eater Components Overview

Every outdoor tool is made up of several key elements that work together to provide optimal performance. Understanding the functions of these components and how they interact can simplify maintenance and repair tasks. Each section plays a specific role in the operation of the machine, from the engine to the external casing. By identifying the core pieces, users can efficiently troubleshoot and ensure everything is in good working order.

Key Components of the Equipment

The main sections of the tool are designed for specific functions, and recognizing each part’s role is essential for effective upkeep. Below are the primary elements involved:

- Engine Housing – Encases the motor and connects the various parts.

- Throttle Assembly – Controls the power output and speed of the device.

- Fuel System – Supplies the engine with the necessary fuel for operation.

- Cutting Mechanism – The system that performs the trimming function, typically involving a rotating head.

- Handle and Grip – The user interface for holding and controlling the device while in use.

Understanding Their Interactions

These components work in unison to ensure smooth operation. For example, the engine housing provides stability to the motor, while the throttle assembly adjusts the output to the cutting mechanism, allowing for varied performance levels. A failure in any one part can disrupt the entire system, which is why it’s important to regularly inspect and maintain all components.

Identifying Key Parts in the Diagram

When maintaining outdoor equipment, having a clear understanding of each essential component is vital. A visual guide that highlights these elements can make it easier to spot any issues and identify which parts may need attention. By carefully reviewing the layout and functions of the individual pieces, you can approach repairs with confidence and accuracy.

Recognizing Important Elements

Several key components make up the operational framework of the tool. These are some of the main sections that should be easily identifiable in the visual guide:

- Power Unit – The central part responsible for energy generation.

- Throttle Control – Regulates speed and power according to user input.

- Drive Shaft – Transfers motion from the motor to the cutting mechanism.

- Safety Features – Includes mechanisms designed to prevent accidents or malfunction.

How to Use the Guide Effectively

By following the reference guide, you can easily locate each of these essential components. It’s important to match each part’s visual representation with its function, ensuring accurate identification during troubleshooting or part replacement. This process simplifies the repair or maintenance procedure, ultimately extending the tool’s lifespan.

Understanding Maintenance and Repair Needs

Proper upkeep of outdoor tools ensures they operate at their best for a long time. Regular maintenance allows users to identify wear and tear before it becomes a bigger issue. Understanding the necessary repairs and knowing when to act can help keep the equipment running smoothly and avoid costly damage.

Routine checks are essential to prevent malfunctions. Inspecting the internal components, fuel system, and cutting elements regularly can pinpoint early signs of damage or inefficiency. Regularly replacing worn-out components before they fail completely ensures optimal performance.

Repairs are often inevitable, especially with frequent use. Knowing how to troubleshoot and identify which parts need attention can simplify the process. Whether it’s replacing a faulty drive mechanism or adjusting the throttle system, addressing issues quickly prevents further damage and ensures the tool is ready for use when needed.