In any complex mechanical or electronic system, knowing how each element interacts with others is essential for efficient operation and troubleshooting. A clear visual representation can greatly assist in understanding the structure and function of individual parts. This guide will focus on helping you navigate the internal workings and key components that make up a specific machine model.

By breaking down the overall setup, you can easily identify where certain parts fit into the system and how they contribute to its functionality. Whether for repair, maintenance, or general knowledge, mastering the layout is critical. The goal here is to offer a comprehensive understanding of the core elements that play a vital role in ensuring smooth performance.

Knowing the layout not only aids in effective repairs but also allows you to prevent potential failures by recognizing early signs of wear or malfunction. Being familiar with the system’s structure empowers you to make informed decisions, ultimately leading to better care and efficiency.

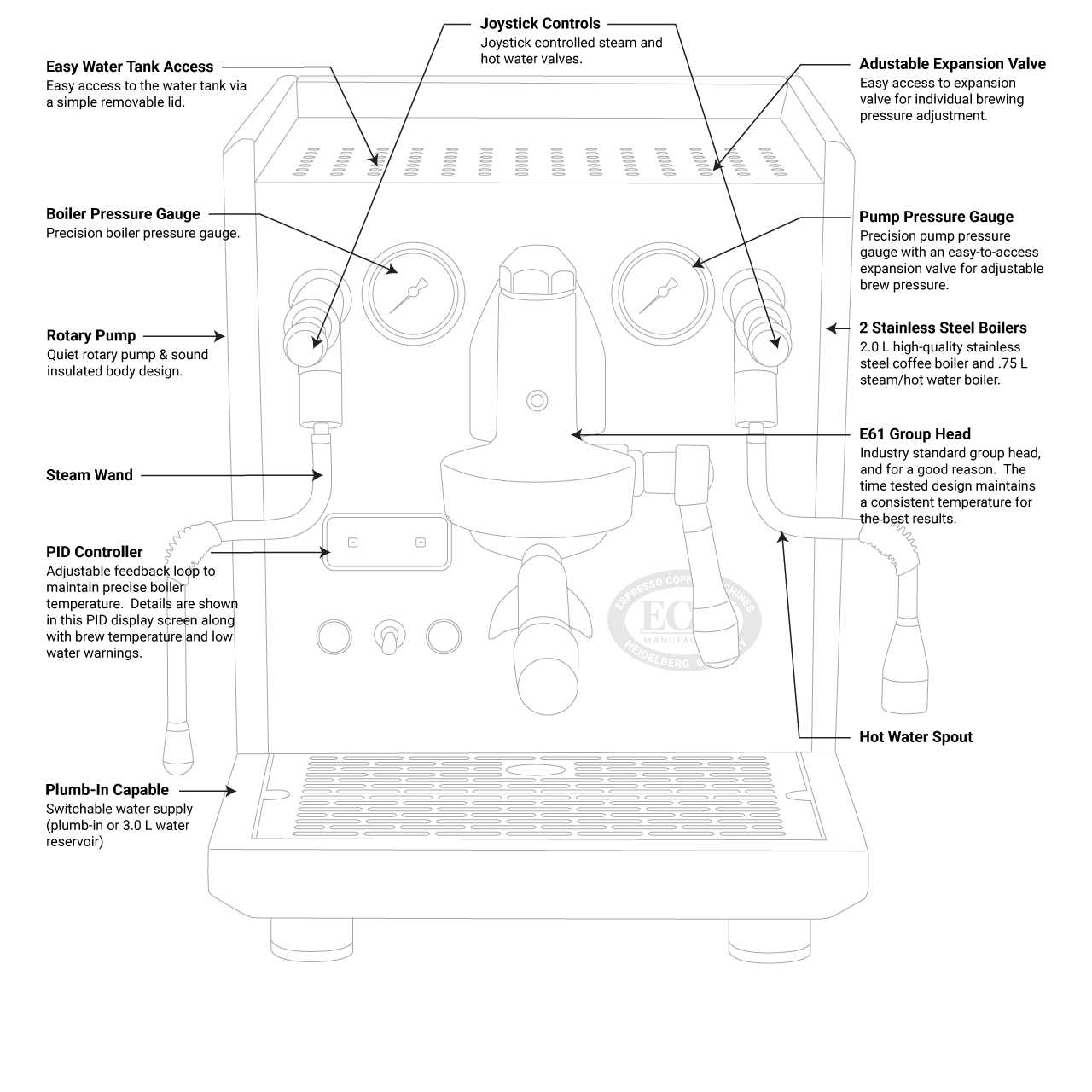

Understanding ECM Synchronika Parts

In every advanced mechanical or electronic system, the individual elements work in unison to ensure optimal performance. Understanding the functionality of each component is essential to mastering the entire machine. This section will provide an overview of the critical components that make up the system, highlighting their roles and how they collaborate to achieve efficiency.

Each part plays a unique role in the system, and knowing their placement and function can make troubleshooting and maintenance more manageable. Below are the key elements found within this machine:

- Control Unit: The central hub that manages all system operations and coordinates signals between various components.

- Heating Element: A crucial component that regulates temperature and ensures consistency during operation.

- Sensor Network: A series of devices that monitor various parameters, such as pressure, temperature, and flow, providing real-time data for optimal performance.

- Power Supply: Supplies the necessary energy for all components to function smoothly and efficiently.

- Actuators: Mechanical parts that convert electrical signals into physical movement, controlling key system functions.

Each component is interconnected, and understanding how one part impacts the others is crucial for troubleshooting any issues that may arise. Being able to identify which part may be malfunctioning allows for quicker resolutions and prolonged machine lifespan.

Key Components in ECM Synchronika System

Every system is made up of interconnected elements that work together to ensure proper functionality. To gain a deeper understanding of how everything operates, it’s important to examine the individual components that drive the system’s overall performance. Each part has a specific role, and recognizing their functions helps in both efficient usage and effective maintenance.

Central Control Mechanism

The heart of the system, the control unit, serves as the central processor. It oversees all operations, managing data from various sensors and coordinating actions across all components. This unit ensures that every function is performed accurately, adjusting processes in real time to maintain optimal performance.

Essential Operational Elements

Several critical components directly influence the performance and efficiency of the system. These include:

- Temperature Regulator: Maintains the necessary heat levels, ensuring consistency in processes.

- Flow Controllers: Ensure that materials or fluids move at the required rate, preventing issues like overpressure or insufficient flow.

- Pressure Sensors: Continuously monitor pressure levels, providing crucial data to the control unit to avoid potential malfunctions.

- Power Supply: Delivers the energy needed for all operations, ensuring that every component functions properly.

These operational elements, working in tandem with the control mechanism, are vital for the system’s overall success. Understanding their individual roles can significantly enhance troubleshooting and ensure smooth and efficient operation.

How to Read ECM Synchronika Diagram

Understanding the layout of a complex system can be challenging, but reading its visual representation is crucial for maintenance, troubleshooting, and efficient operation. These schematic representations provide a map of the internal structure, showing how each component is connected and how they interact. Knowing how to interpret these visuals allows you to identify potential issues quickly and ensures you can perform repairs or adjustments accurately.

Key Symbols and Indicators

Each system has a set of standardized symbols that represent various components. These symbols are used consistently throughout the schematic to identify specific parts. Familiarizing yourself with these symbols is the first step in reading the layout:

- Rectangles: Typically represent electrical devices such as relays or switches.

- Circles: Often indicate sensors or mechanical parts that require monitoring.

- Lines: Show the connections between components, indicating electrical or fluid pathways.

Interpreting Connections and Flow

Once you’re familiar with the symbols, the next step is understanding how the components are interconnected. The flow of energy, data, or materials is usually represented by arrows or lines, which help you visualize how each part interacts with others. For example, an arrow pointing from one component to another can indicate the flow of power or control signals. Carefully following these connections helps you understand the system’s operation and diagnose potential faults.

By mastering these techniques, you can confidently navigate the schematic and make informed decisions about the system’s maintenance and performance.