For anyone working with a chainsaw, understanding the individual elements of the machine is crucial for proper maintenance and repairs. A comprehensive visual reference can greatly simplify the process of identifying and addressing issues that may arise. Such references are indispensable for both professionals and enthusiasts looking to ensure the longevity and efficiency of their equipment.

Having a clear, organized layout of the tool’s structure allows users to quickly locate specific parts, understand their function, and know how to replace or repair them when needed. This resource can save both time and effort, enabling smoother operations and fewer mistakes during repairs.

Whether you’re a beginner or an experienced user, mastering the parts of your machine is key to maintaining its performance. A well-maintained chainsaw not only lasts longer but also operates more safely and efficiently. A proper guide will support this by providing essential visual clarity and organization, ensuring that you’re always prepared to tackle any maintenance task with confidence.

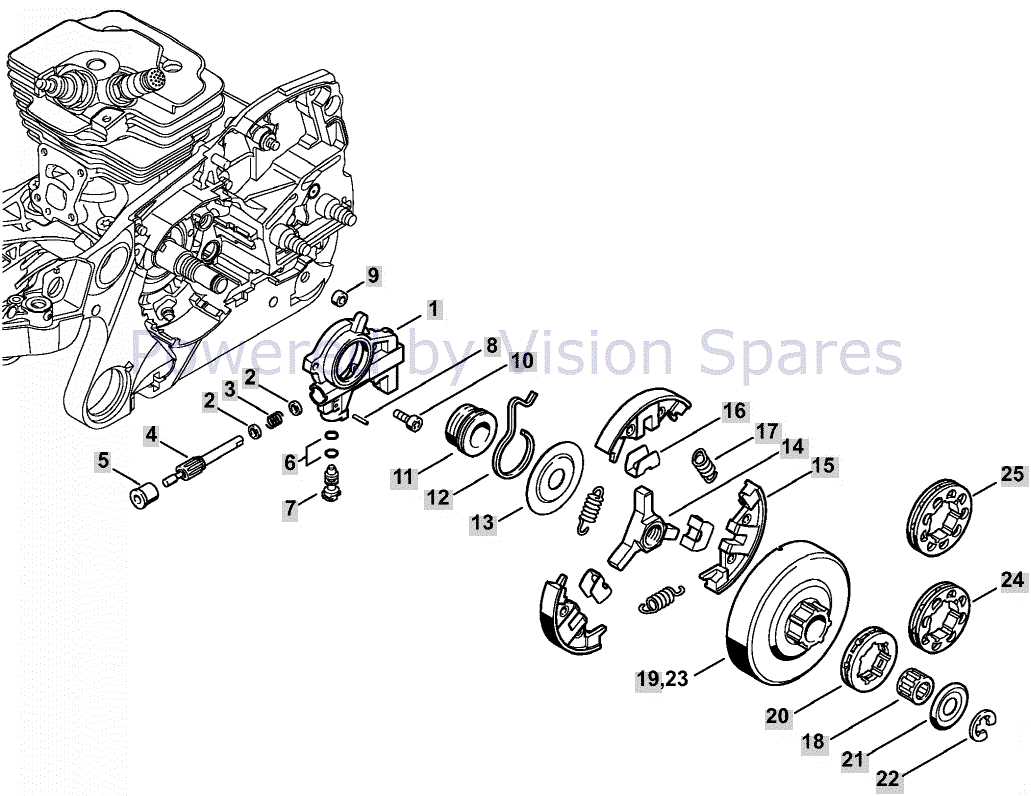

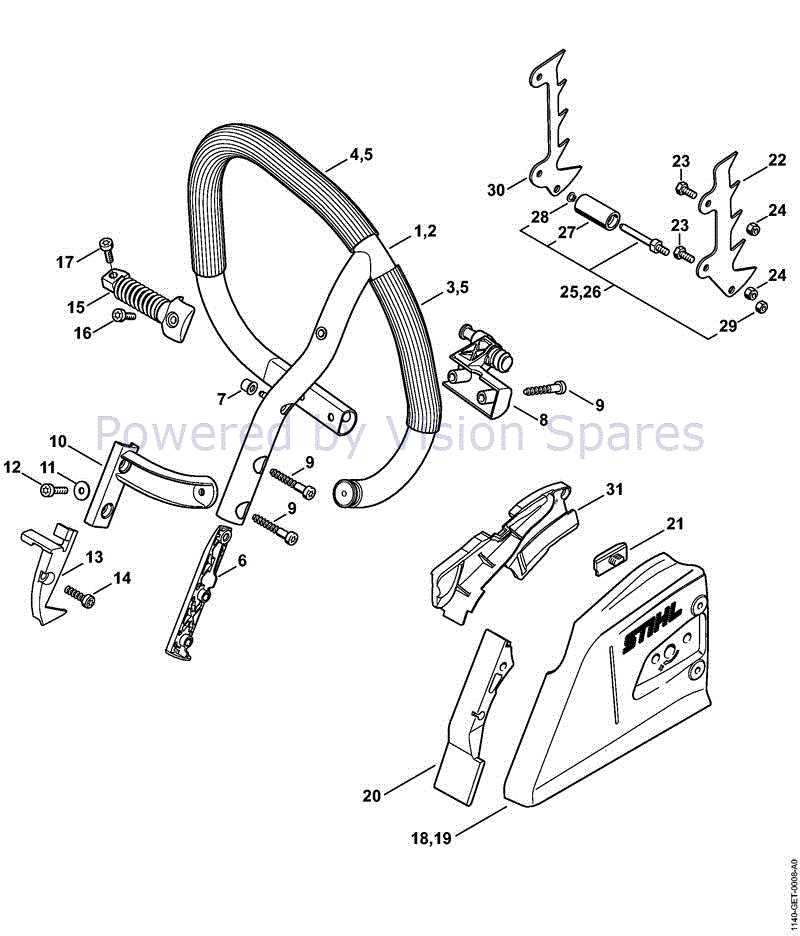

Understanding Chainsaw Components

Every chainsaw consists of a variety of interconnected elements that work together to ensure its optimal functionality. Understanding these components is vital for maintaining the tool’s performance, diagnosing issues, and making repairs. Each part serves a specific purpose, from the engine to the cutting mechanism, and contributes to the overall effectiveness of the machine.

Key Elements of a Chainsaw

The most crucial elements include the power unit, fuel system, and cutting system. These components are responsible for the chainsaw’s ability to operate smoothly and effectively. The power unit generates the energy needed to drive the tool, while the fuel system ensures that the engine has the necessary supply for combustion. The cutting system includes the chain and bar, which work together to perform the primary task of cutting through wood.

Maintenance and Troubleshooting

Regular maintenance is essential for keeping each part in working order. Knowing how to properly care for the engine, clean the fuel system, and replace the cutting elements will extend the tool’s lifespan. Additionally, understanding how each component interacts allows for faster troubleshooting, making it easier to identify where problems may arise and how to resolve them quickly.

Where to Find the Parts Layout

Locating a detailed visual representation of your machine’s components is essential for anyone involved in maintenance or repairs. These resources provide clear, organized views of the tool’s structure, allowing users to easily identify and replace parts when necessary. Accessing such a guide can save time and ensure that you are working with the correct information.

Official Manufacturer Websites

One of the most reliable places to find an accurate parts layout is through the official website of the manufacturer. Many brands offer downloadable resources that show all the components of their products. These can be found under support or product manuals sections, often available for free. The official resources ensure that you have access to the most up-to-date and precise information available.

Online Retailers and Third-Party Sites

If the manufacturer’s website doesn’t provide what you need, online retailers and third-party websites can also be valuable sources. Websites that specialize in equipment or tools often offer detailed guides, including visual layouts. These can be helpful for identifying parts quickly and purchasing replacements from the same site.

How to Use the Layout for Repairs

Having access to a visual layout of your machine’s structure can significantly simplify the repair process. It helps identify each component, making it easier to find issues and determine which parts need attention. Using this reference correctly allows for a more efficient and accurate repair procedure, ensuring that each step is performed properly.

Step-by-Step Guide

Start by reviewing the layout carefully to familiarize yourself with the location and function of each part. When a problem arises, consult the guide to locate the malfunctioning component. This visual reference helps you understand how the parts fit together, which is crucial when disassembling and reassembling the machine during repairs.

Ensuring Correct Replacements

The layout also aids in identifying the exact components that need replacement. By cross-referencing the visual representation with your machine, you can ensure you’re ordering the correct parts. This reduces the likelihood of purchasing incorrect replacements and speeds up the repair process.