When working with machinery or equipment, having a clear understanding of its internal elements is essential for effective maintenance and repair. Being able to identify the specific components that make up the machine helps in troubleshooting issues and performing routine upkeep. A visual representation of these parts can make the process more straightforward, ensuring you can quickly locate and replace any faulty components.

Detailed illustrations offer a structured way to examine how various pieces fit together, enabling you to follow the correct procedures. These resources can also guide you in finding the right replacement elements, which is crucial for maintaining the functionality of the system. Whether you’re a seasoned technician or a novice, such tools provide valuable insight into the internal workings of the machine.

Having access to such detailed visual guides not only saves time but also reduces the risk of errors during repairs. With the right approach, you can confidently address any issues, ensuring the machine runs smoothly for years to come.

Understanding the Craftsman T100 Parts

To maintain any machine effectively, it’s crucial to recognize the essential components that enable its operation. Understanding each element’s function within the system can lead to quicker identification of problems and more accurate repairs. This section focuses on examining the key elements that contribute to the machine’s performance, offering a clearer view of how everything fits together.

Each key component serves a distinct role, and understanding their relationships is vital for effective troubleshooting and maintenance. The following are some of the main groups of elements typically found in the machinery:

- Drive Mechanisms – These include the parts responsible for transferring power throughout the system, ensuring smooth operation and movement.

- Control Systems – The components that manage the flow of energy and direct the machine’s functions based on user inputs.

- Support and Frame Elements – These elements provide the structure and stability, ensuring that the machine remains steady during operation.

- Safety Components – Parts designed to protect the user from harm, including sensors, covers, and emergency stop functions.

- Consumables and Maintenance Items – Elements that wear down over time and require regular replacement to keep the equipment functioning efficiently.

By understanding these different groups, it becomes easier to pinpoint potential issues, allowing for more efficient and cost-effective repairs. Additionally, knowing the general roles of these components ensures you can approach troubleshooting in a systematic manner, reducing downtime and avoiding unnecessary complications.

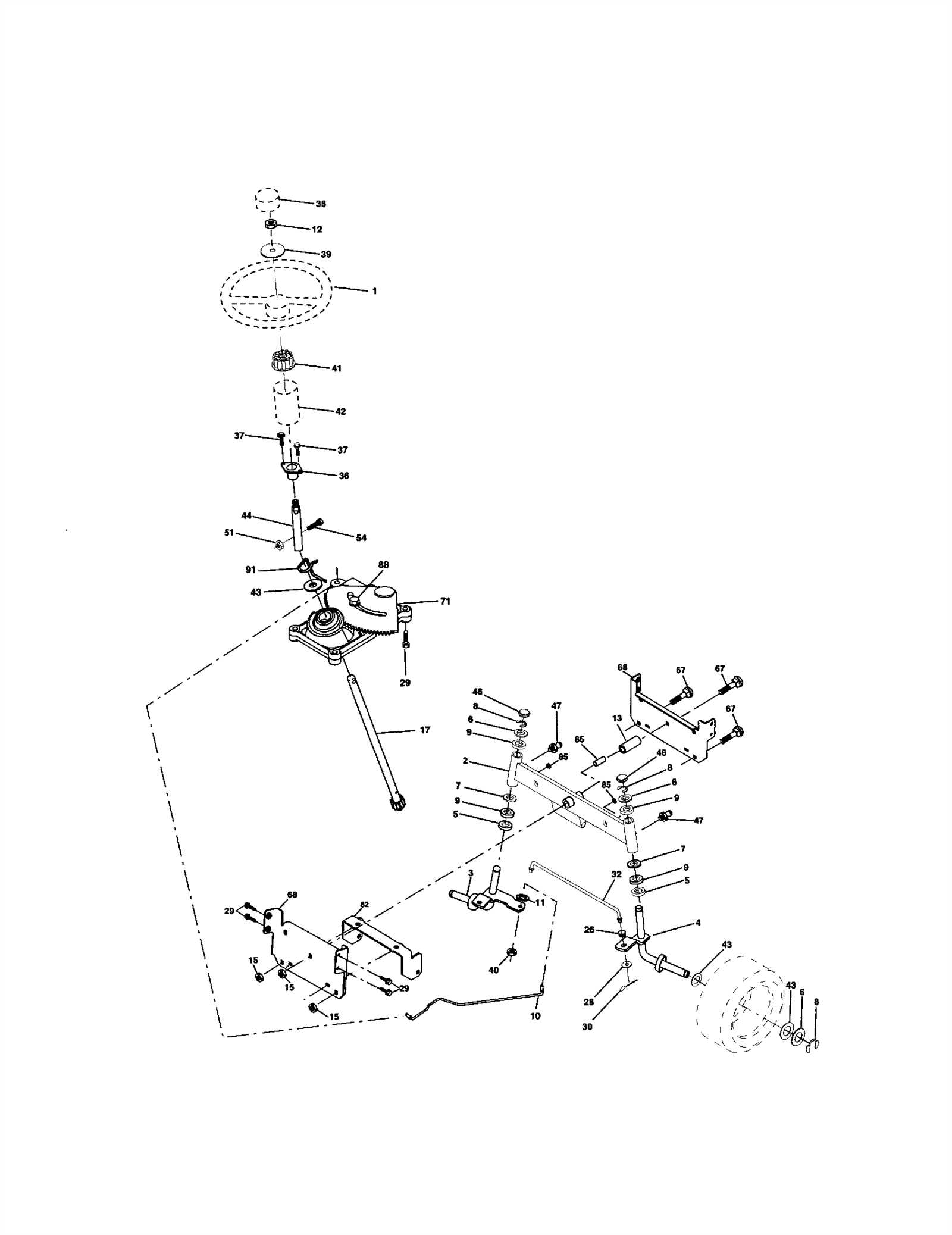

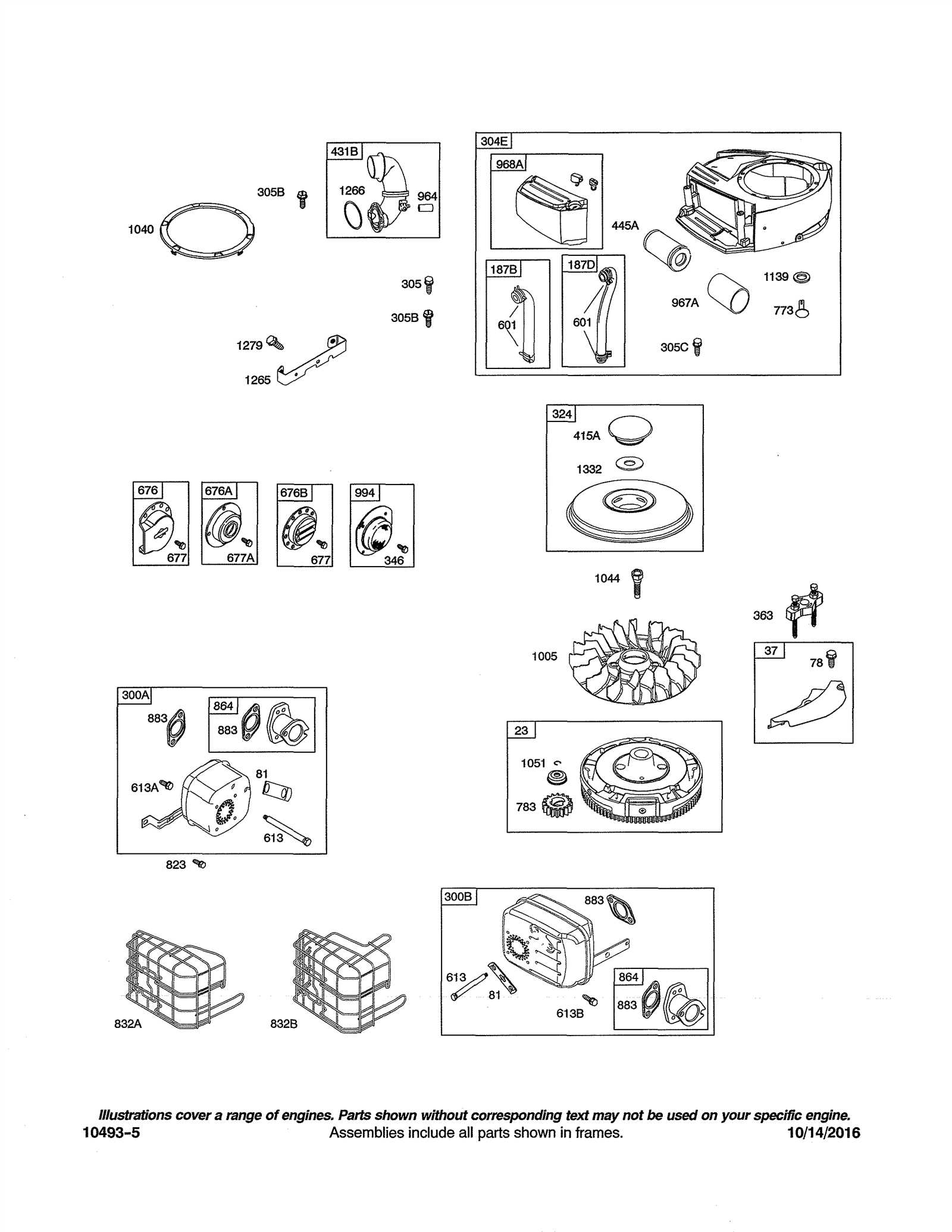

Identifying Key Components in the Diagram

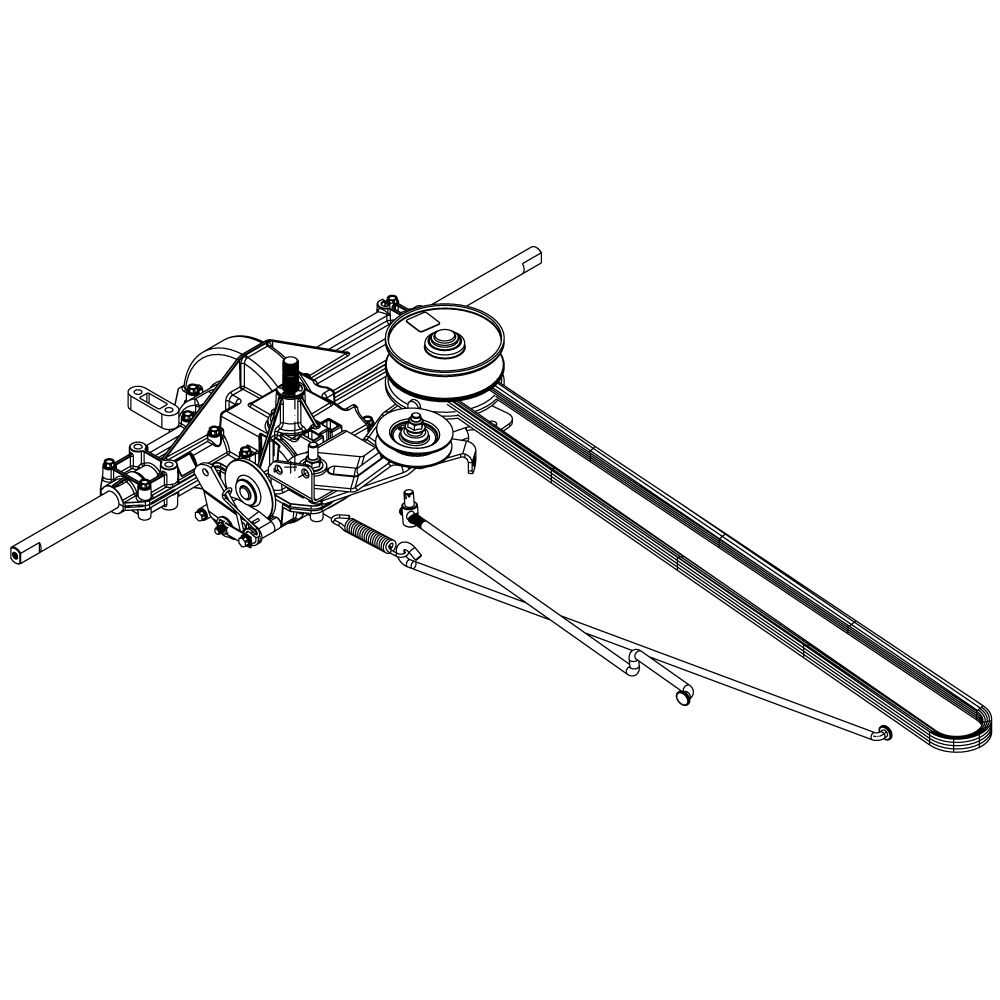

Understanding the structure of a machine begins with recognizing the individual elements that contribute to its functionality. Visual representations play a significant role in highlighting the specific components that make up the entire system. By accurately identifying these elements, users can gain a better grasp of the assembly, which is crucial for repairs, replacements, and overall maintenance.

In any machine, the most important components often include power sources, drive mechanisms, and control systems. These elements are highlighted in a well-organized visual guide, allowing you to pinpoint their locations and understand how they interact within the larger system. It’s essential to focus on these key components, as they often affect the overall performance of the equipment.

Furthermore, recognizing the different parts in the illustration aids in troubleshooting. If something goes wrong, understanding the precise role of each element can help identify where the issue lies. Whether it’s a broken link in the power transmission system or a malfunctioning control unit, pinpointing the exact part is the first step towards an efficient resolution.

How to Use the Parts Diagram for Repairs

When it comes to repairing machinery, a clear visual guide can significantly streamline the process. By referencing an accurate illustration of the system, you can quickly locate the components that need attention, ensuring a more efficient and focused repair procedure. This section outlines the best practices for utilizing a visual representation of the system to identify faulty parts and perform necessary fixes.

The first step in using the visual guide for repairs is to familiarize yourself with the layout. Look for labels or numbered sections that correspond to the components of the machine. Once you know where each part is located, it becomes easier to troubleshoot and identify which areas need maintenance or replacement.

Next, compare the components shown in the visual guide with the physical system. If something is malfunctioning, cross-reference the damaged or worn-out part with the diagram to confirm the issue. This will help you avoid unnecessary disassembly and ensure you’re focusing on the correct area. Once identified, use the guide to order replacement components or consult manuals for step-by-step instructions on how to properly remove and install them.

Finally, by continuously referring to the guide during the repair process, you can ensure that all components are correctly reassembled and functioning as they should. Using the visual tool in this way can reduce errors, save time, and extend the life of your equipment.