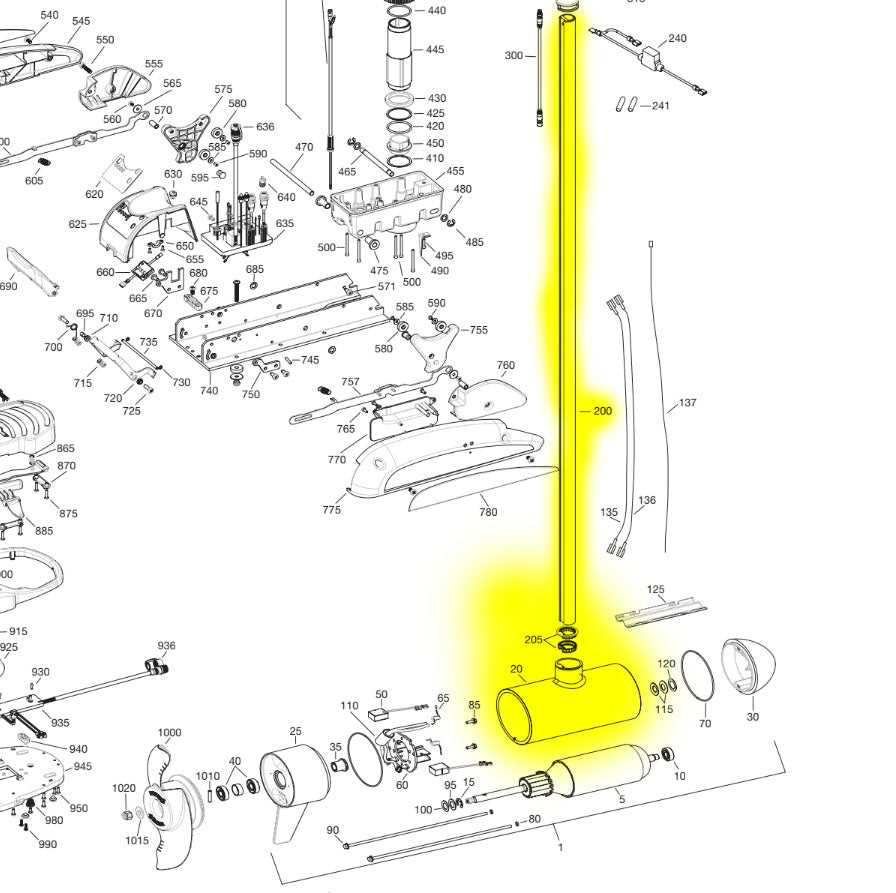

Every trolling motor consists of various essential elements that work together to ensure smooth performance on the water. Whether you’re repairing, replacing, or upgrading certain components, having a clear understanding of how each piece fits into the overall system is crucial. Proper maintenance and care can extend the life of your equipment and prevent costly repairs.

Identifying each individual component and knowing its role in the system is the first step to effective troubleshooting and maintenance. From the motor housing to the propeller, each part plays a vital role in achieving maximum efficiency.

With a detailed visual reference, you can quickly locate the parts that need attention. Whether you’re an experienced boater or a novice, learning how to properly identify and work with the motor’s different elements will enhance your understanding and help keep everything running smoothly.

Understanding the Trolling Motor Components

A trolling motor consists of multiple key elements that together enable efficient movement and control of your boat. Each component plays an integral role, ensuring the smooth operation of the system. Understanding these parts helps you make informed decisions when performing maintenance, upgrades, or repairs.

From the motor housing to the propeller, each section serves a unique function. For instance, the drive shaft connects the motor to the propeller, while the steering mechanism controls the direction of the motor. Each piece is essential for optimal performance, and recognizing them can prevent issues before they arise.

Regularly maintaining and inspecting these components ensures that your motor remains in top condition. By knowing the role of each part, you’ll be able to troubleshoot effectively and take the right actions to preserve the longevity and efficiency of your equipment.

Step-by-Step Guide to Trolling Motor Components

Maintaining and repairing your boat’s propulsion system requires a clear understanding of its individual elements. By following a structured process, you can easily identify and replace any malfunctioning components. This guide will walk you through each step of handling the motor’s key components.

Start with the motor housing, where most of the internal mechanisms are housed. It’s essential to ensure the motor housing is clean and free from debris, which can cause damage to the internal components over time. Once you open it up, check the connections to ensure they are intact.

Next, focus on the propeller and drive shaft, the parts responsible for the motor’s movement. Inspect the blades for damage or wear and tear. If the propeller is loose or misaligned, it may hinder your motor’s performance. Replacing these parts when needed is crucial for smooth operation.

Lastly, check the electrical connections and wiring. Ensuring that all connections are secure will prevent any disruptions in power delivery. A simple visual inspection can help identify any corrosion or fraying wires that might need attention.

How to Use the Trolling Motor Reference

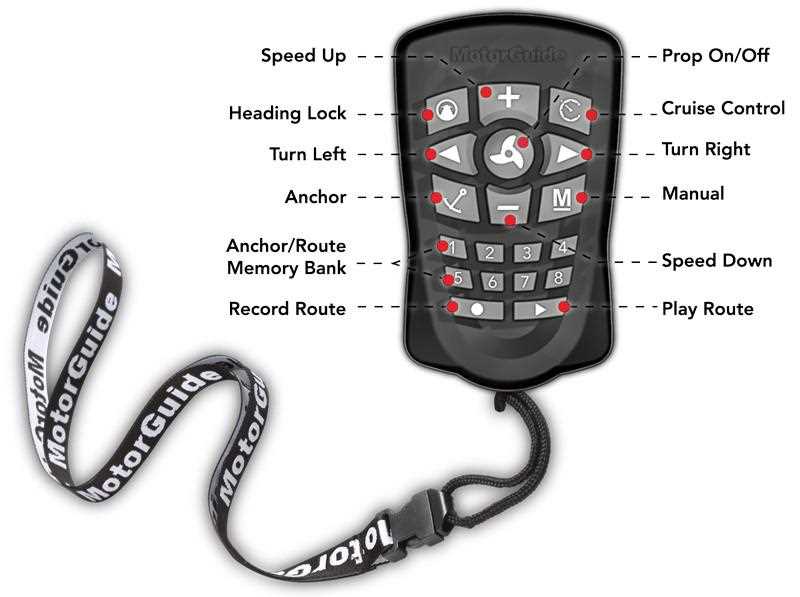

A visual reference of the motor’s components can significantly simplify troubleshooting and repairs. By providing clear images or schematics, it allows you to easily identify and locate individual elements of the system. Knowing how to effectively use this tool can save time and ensure accurate maintenance.

Start by familiarizing yourself with the layout of the reference. Each section of the motor is typically labeled, helping you pinpoint the exact location of any part you need to inspect or replace. Take note of the symbols or numbers associated with each component for easier identification.

Once you’ve identified the needed component, use the reference to find the part’s specific name and any relevant details, such as part numbers or specifications. This information is invaluable when ordering replacements or performing precise repairs.