When working with power tools, understanding their structure and individual elements is crucial for proper maintenance and repairs. Every tool consists of numerous components that interact to perform a specific task. Familiarity with these parts can help users identify issues quickly and ensure smooth operation over time.

In this article, we will explore how to read and interpret detailed schematics of power tools. By breaking down the different sections and their functions, you can gain better insight into how each part contributes to the tool’s overall performance. Knowing what each component does will allow you to address malfunctions more effectively and select the right replacement when needed.

With this knowledge, both amateurs and professionals alike can extend the lifespan of their tools, minimize downtime, and perform necessary repairs with confidence. Whether you are troubleshooting or replacing a worn-out part, having a clear understanding of the tool’s construction is invaluable.

Understanding the Milwaukee Band Saw Components

Every power tool consists of various key elements, each playing a specific role in its operation. Recognizing these components and understanding their functions is essential for anyone using or maintaining the tool. This knowledge ensures that users can keep their equipment in top condition, troubleshoot issues more effectively, and replace worn parts when necessary.

The internal structure of a tool includes both moving and stationary parts that work together seamlessly. Each component is designed to contribute to the overall efficiency, whether it is a part responsible for the motor’s power, the mechanism that controls motion, or the sections that provide stability and durability. Knowing the role of each section can help users prevent issues, as well as recognize early signs of wear or malfunction.

By familiarizing yourself with the essential elements of the tool, you will be better equipped to address maintenance needs or replace damaged components. Understanding the construction of your tool is not only beneficial for repairs but also for optimizing its use and ensuring long-term performance.

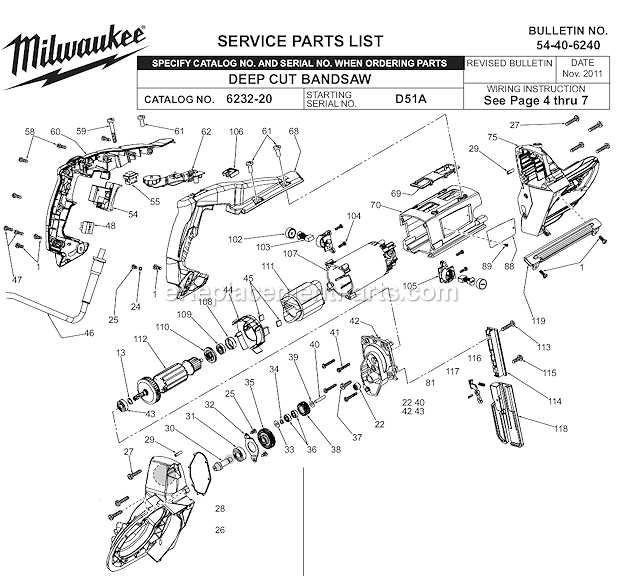

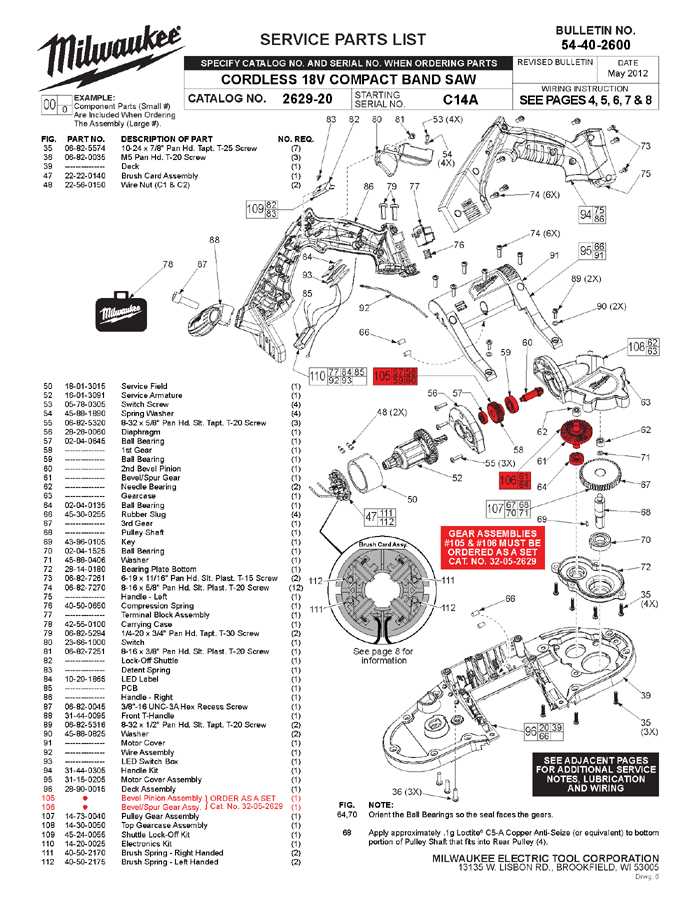

How to Read the Parts Diagram Effectively

Understanding how to interpret technical illustrations is an essential skill for any tool owner. These visuals provide a clear representation of how individual components are arranged and connected within the tool. Effectively reading these schematics allows you to identify each element, understand its function, and make informed decisions when it comes to maintenance or repairs.

Familiarizing Yourself with the Key Sections

The first step in reading an illustration is to familiarize yourself with the different sections. Most schematics are divided into categories that group similar components, making it easier to locate specific parts. Take time to learn how these sections are organized and how each part is labeled. This will help you quickly navigate the diagram and find the relevant information you need.

Interpreting Symbols and Labels

Another critical aspect is understanding the symbols and labels used in the visual. These often represent specific functions, part numbers, or sizes. Knowing what each symbol stands for is crucial in making accurate assessments of the tool’s design and identifying the right parts for repairs. Always refer to the key or legend, if available, to ensure proper interpretation of these markings.

Common Issues and Replacement Parts for 6232-20

Like all power tools, common issues can arise over time, affecting performance and efficiency. Recognizing these problems early and knowing which components need replacement is key to maintaining the tool’s functionality. Whether it’s a loss of power, unusual noise, or difficulty in operation, identifying the root cause and replacing the faulty parts can often restore the tool to its optimal state.

One of the most frequent issues is motor malfunction, which can stem from wear and tear on internal components. Other common problems include worn belts or damaged tensioning mechanisms, which can lead to decreased performance or failure to operate correctly. For each of these problems, specific replacement components are available to resolve the issue and get the tool running smoothly again.

Ensuring that the correct replacements are used is essential. Always refer to the schematic and part numbers to find the exact components needed. This will prevent further damage and maintain the tool’s reliability over time. Regular maintenance and timely replacement of worn components can extend the lifespan of the equipment and improve overall user experience.