Understanding the inner workings of your outdoor machinery is crucial for keeping it in top condition. Proper knowledge of each component can significantly enhance performance and longevity. With the right approach, maintaining your machine becomes a simple and rewarding task.

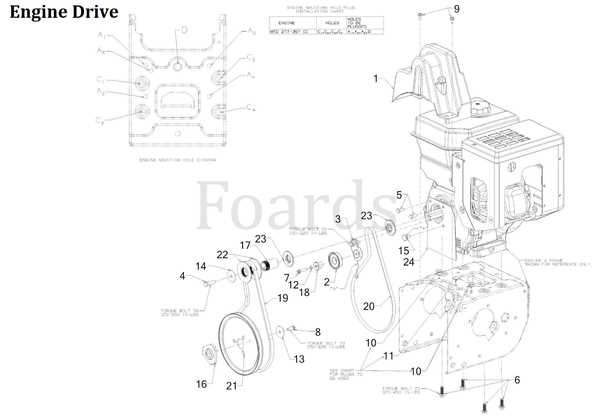

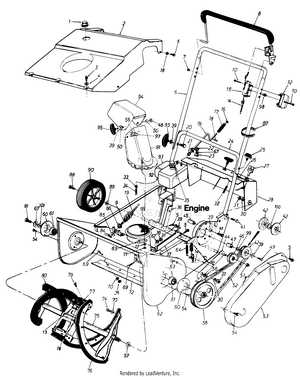

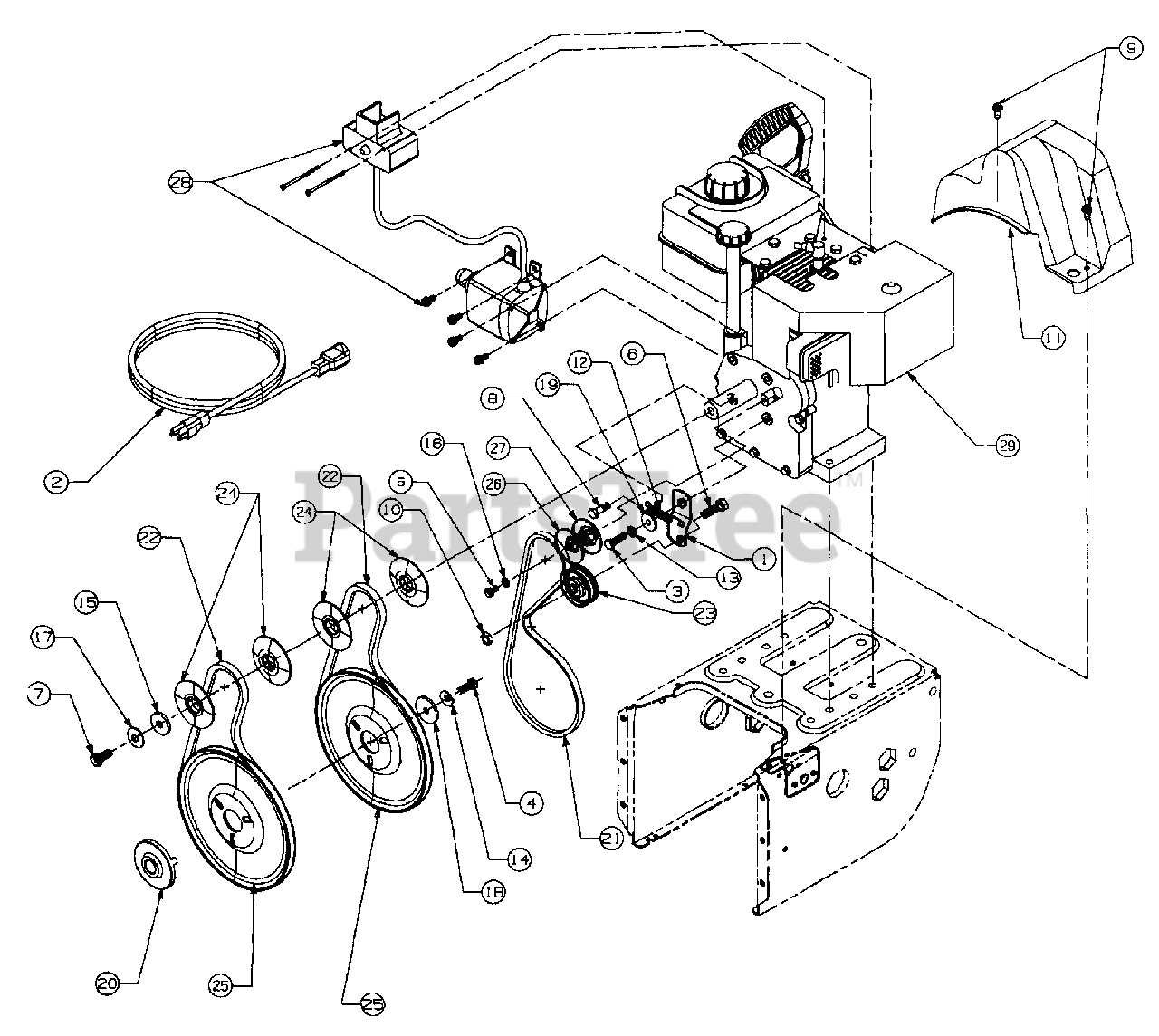

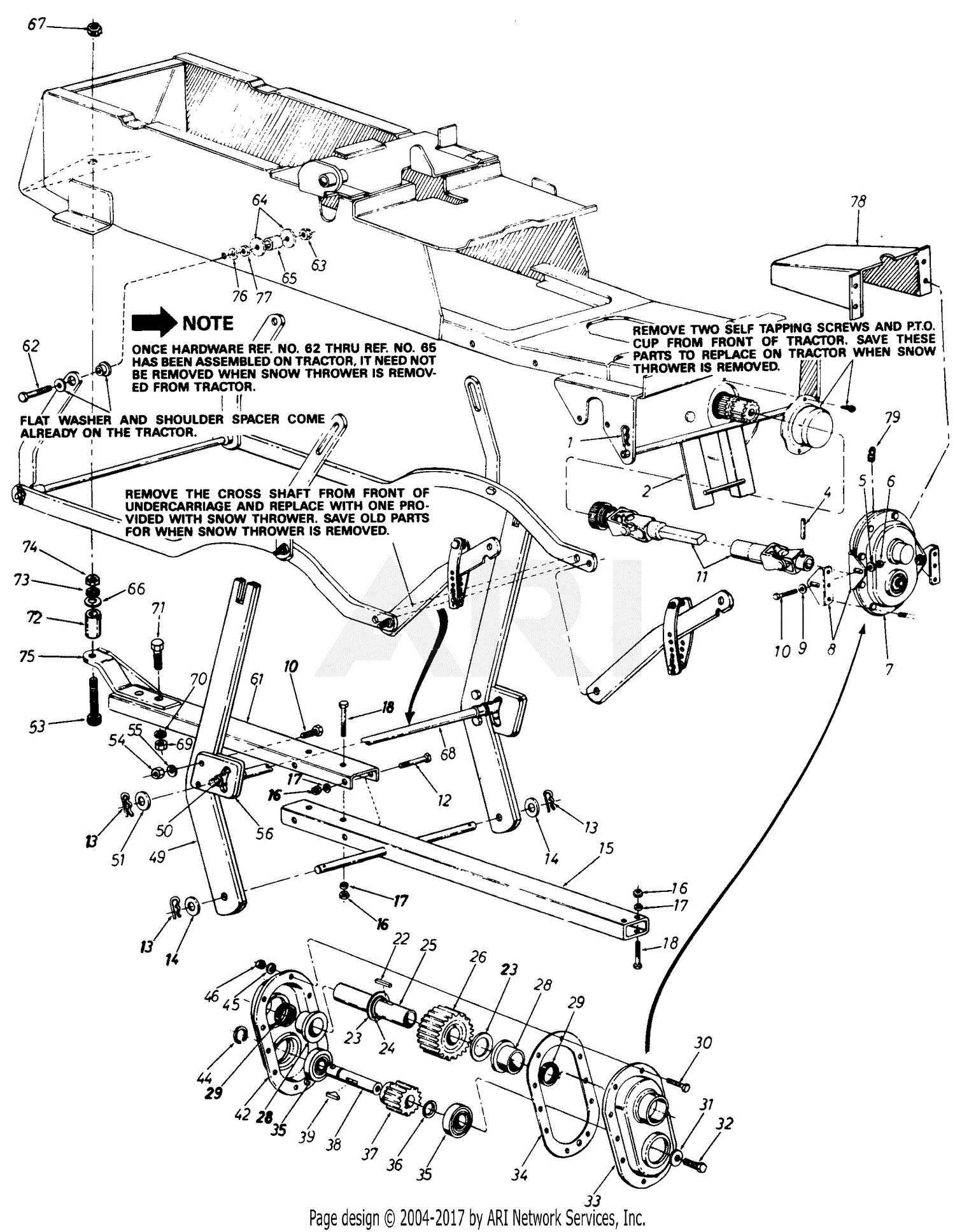

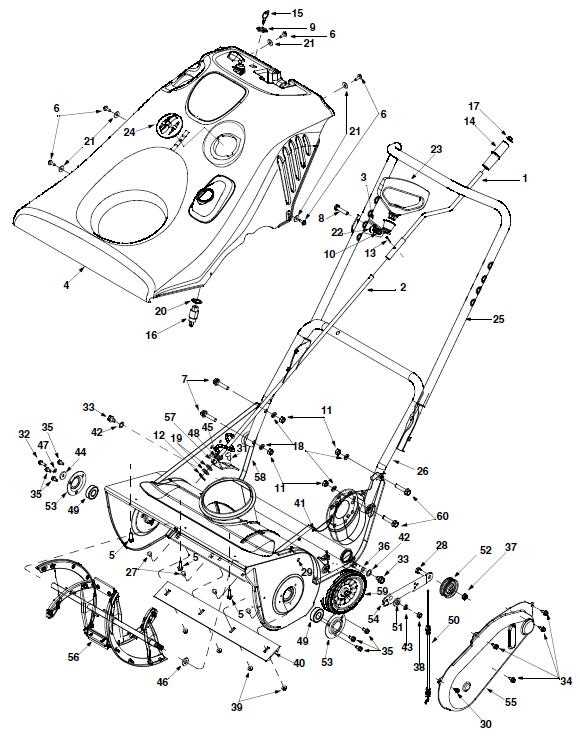

Identifying key elements and knowing their function allows for quicker troubleshooting and easier repairs. It’s important to have a clear view of the different sections and their roles, whether for routine checks or part replacements.

Having a comprehensive view of the assembly can prevent unnecessary damage and save time in the long run. Whether you are a professional or a beginner, familiarizing yourself with these essentials ensures smoother operation and better upkeep.

Understanding Equipment Components

Every outdoor machine consists of a variety of crucial elements, each playing a specific role in ensuring the device operates efficiently. Recognizing the function of these components helps in understanding how they work together to provide the best performance. A solid grasp of the machinery’s layout allows for easier troubleshooting and effective maintenance.

Each piece, from the motor to the housing, contributes to the overall function and reliability of the system. The essential parts include those responsible for moving, controlling, and powering the equipment. Knowing their location and purpose aids in quick identification and makes repairs more manageable.

Familiarizing yourself with these key components is the first step toward performing routine inspections and ensuring the machine remains in peak condition. Being able to distinguish the different sections allows for efficient maintenance and can help prevent major malfunctions before they occur.

How to Identify Equipment Components

Proper identification of essential components in your machine is vital for smooth operation and maintenance. Recognizing each element’s function ensures that you can troubleshoot issues effectively and perform repairs when necessary. Understanding how to pinpoint specific parts will also save time during inspections and maintenance routines.

Start with the main assembly, where the engine, wheels, and other large components are located. These serve as the foundation for the entire system and are typically easy to identify based on their size and function. From there, move to the smaller parts that support operation, such as control cables and linkages, which are often less visible but equally important.

Many modern devices come with clear labels or color-coded elements to assist in identifying parts. If this is not the case, consulting the user manual or reference materials can provide a comprehensive guide to understanding the setup. Always ensure that you have a full picture of the equipment’s layout before attempting any repairs or adjustments.

Tips for Replacing Equipment Components

Replacing faulty components is a crucial part of maintaining your machine’s efficiency. When a part begins to wear out, it’s important to know how to properly replace it to avoid further damage and ensure the system operates at its best. Following a few essential guidelines can make the process easier and prevent unnecessary complications.

First, always ensure you have the correct replacement for the damaged component. Using the right size and type of part ensures that the machine will function as expected. Refer to the manufacturer’s manual or specifications to verify compatibility before purchasing replacements.

Next, take time to clean the surrounding areas before starting the replacement. Dirt, debris, and old lubricants can hinder the process and lead to additional wear. Additionally, it’s advisable to keep track of the screws and small pieces as you disassemble parts to avoid losing anything important during reassembly.

Finally, after replacing the component, perform a thorough test to ensure everything is working as it should. Listen for unusual sounds or observe any irregular behavior, and address potential issues immediately. Regular maintenance and timely replacements can significantly extend the life of your equipment.