Understanding the intricate structure of any off-road vehicle is crucial for its maintenance and repair. Each part plays a unique role, and knowing how they work together helps ensure longevity and optimal performance. Whether you’re a mechanic or a hobbyist, having access to a detailed visual map of your vehicle’s configuration can simplify troubleshooting and parts replacement.

By examining a comprehensive layout of the different systems and components, you’ll be better equipped to identify issues and source replacements. This approach minimizes downtime and avoids costly mistakes. Proper knowledge of each element within the vehicle’s framework allows for more efficient repairs and upgrades.

Efficient maintenance starts with understanding the core components. Familiarizing yourself with their location and function can save time, reduce errors, and improve overall vehicle handling. This guide will provide insight into the essential components, their arrangement, and tips for easy identification and replacement.

Understanding Vehicle Components

To ensure optimal performance and longevity, it’s essential to grasp the layout and functionality of each individual element within your vehicle. By understanding how the various systems interconnect, you can more effectively manage maintenance tasks, troubleshoot issues, and perform upgrades when necessary.

A thorough knowledge of your vehicle’s structure can greatly improve your repair efficiency. Every element, from the frame to the smallest fasteners, plays a role in the overall functionality. Familiarity with the key components allows for quicker diagnosis and proper handling of any mechanical issues that may arise.

Here are the main areas to focus on when examining the vehicle’s system:

- Chassis and Frame – Provides the foundation for all other systems and supports the entire structure.

- Suspension System – Ensures a smooth ride by absorbing shocks and managing terrain challenges.

- Powertrain – Transmits power from the engine to the wheels, including key components like the gearbox and driveshaft.

- Steering and Control – A vital system that ensures precise handling and maneuverability.

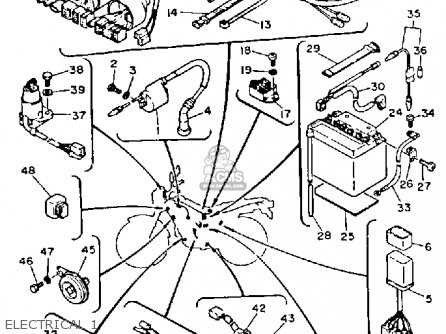

- Electrical Components – Includes wiring, sensors, and the battery, all of which ensure the functionality of lights, ignition, and other systems.

Understanding these core systems will allow you to address potential issues with greater precision. It’s important to always refer to a comprehensive layout to identify the specific location and function of each component within the overall framework. This knowledge will guide you in making informed decisions when replacing parts or performing maintenance tasks.

How to Use the System Layout Effectively

When it comes to maintenance or repairs, knowing how to read and utilize a comprehensive schematic of your vehicle is invaluable. A detailed visual reference helps you locate components quickly, ensuring that you can work more efficiently and make informed decisions about replacements or adjustments.

Identifying Key Components

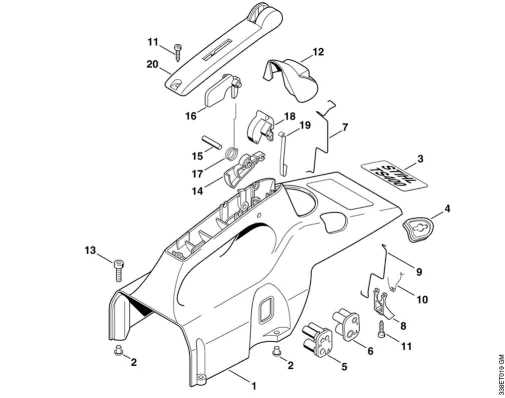

The first step in using the schematic is understanding the layout. Each section of the diagram represents a different system, such as the engine, suspension, or electrical components. Begin by familiarizing yourself with the general structure and flow of the components. Identify the main systems and their individual parts to get an overview of how everything connects.

Locating Specific Parts

Once you have a general understanding of the layout, use the reference to locate the exact component you need to address. The schematic will often include numbers or labels next to each part, which you can cross-reference with a parts list for precise identification. This is especially useful when dealing with complex systems that involve multiple interconnected elements.

By using this tool effectively, you can reduce the chances of overlooking crucial details and streamline your repair or maintenance process. Familiarity with the layout ensures that you can access the correct parts quickly, minimizing downtime and reducing the likelihood of errors during repairs.

Common Issues and Replacement Components

Every vehicle faces wear and tear over time, with certain systems and elements being more susceptible to damage or failure. Recognizing the most common issues can help you anticipate problems before they escalate, allowing for timely replacements and repairs. Familiarizing yourself with the most frequent malfunctions and the corresponding replacements ensures your vehicle runs smoothly for years to come.

Engine-related issues are often the first to be noticed, especially when there are signs of poor performance or strange noises. These problems may stem from worn-out ignition components, air filters, or fuel injectors. Regular maintenance and timely replacement of these parts can prevent engine failure and ensure optimal function.

Suspension system failures are another common issue. Over time, shocks and struts can wear out, affecting ride quality and stability. Replacing these elements with high-quality replacements can restore handling and comfort, ensuring your vehicle can handle rough terrains with ease.

Other frequent issues include malfunctioning electrical components, such as the battery, wiring, and sensors, which can disrupt functionality and cause operational failures. Regular inspection and replacing faulty components will help maintain reliable operation of electrical systems.

By being proactive and replacing faulty components before they cause further damage, you can extend the life of your vehicle and avoid expensive repairs in the future. Always use high-quality, compatible replacement components to ensure long-term performance and reliability.