When maintaining or repairing your tools, understanding how all the components fit together is crucial for efficient operation. Having a clear overview of the various parts and their functions ensures smoother repairs and helps avoid unnecessary errors. This guide is designed to provide you with essential insights into the internal workings of your equipment.

Whether you’re a professional or a DIY enthusiast, being able to identify and replace specific elements without confusion can save you time and money. By familiarizing yourself with the various sections and connections, you’ll be equipped to handle common issues and perform regular upkeep with confidence.

Understanding these components also aids in troubleshooting problems, as recognizing the signs of wear or malfunction in individual parts can point directly to the source of the issue. This approach not only improves the longevity of your tool but also enhances its overall performance over time.

Understanding Key Tool Components

Every mechanical device consists of a series of interconnected elements that work together to ensure smooth operation. A deep understanding of these components is essential for anyone looking to maintain or repair their equipment efficiently. From the power source to the smaller internal pieces, each element plays a critical role in the overall functionality of the tool.

Core Mechanisms of Operation

The heart of any tool lies in its core mechanisms that provide the power and motion required for its tasks. These components typically include motors, gears, and drive mechanisms that work in tandem. By knowing how each part operates, it becomes easier to diagnose issues and replace malfunctioning sections. Regular maintenance of these core elements helps prevent breakdowns and extends the life of the tool.

Supporting Elements and Functions

In addition to the primary functioning components, there are also supporting elements that contribute to the overall performance. These include safety features, ergonomic adjustments, and housing structures that protect internal parts from damage. Understanding these secondary parts ensures that the tool remains safe to use and operates at peak efficiency, minimizing wear and tear on the more critical pieces.

How to Identify Tool Components

Accurate identification of tool elements is vital for effective maintenance and repair. When something malfunctions, knowing the exact component to replace or inspect can save both time and effort. Whether you’re dealing with wear and tear or a sudden breakdown, having the ability to recognize specific parts ensures you address the root cause efficiently.

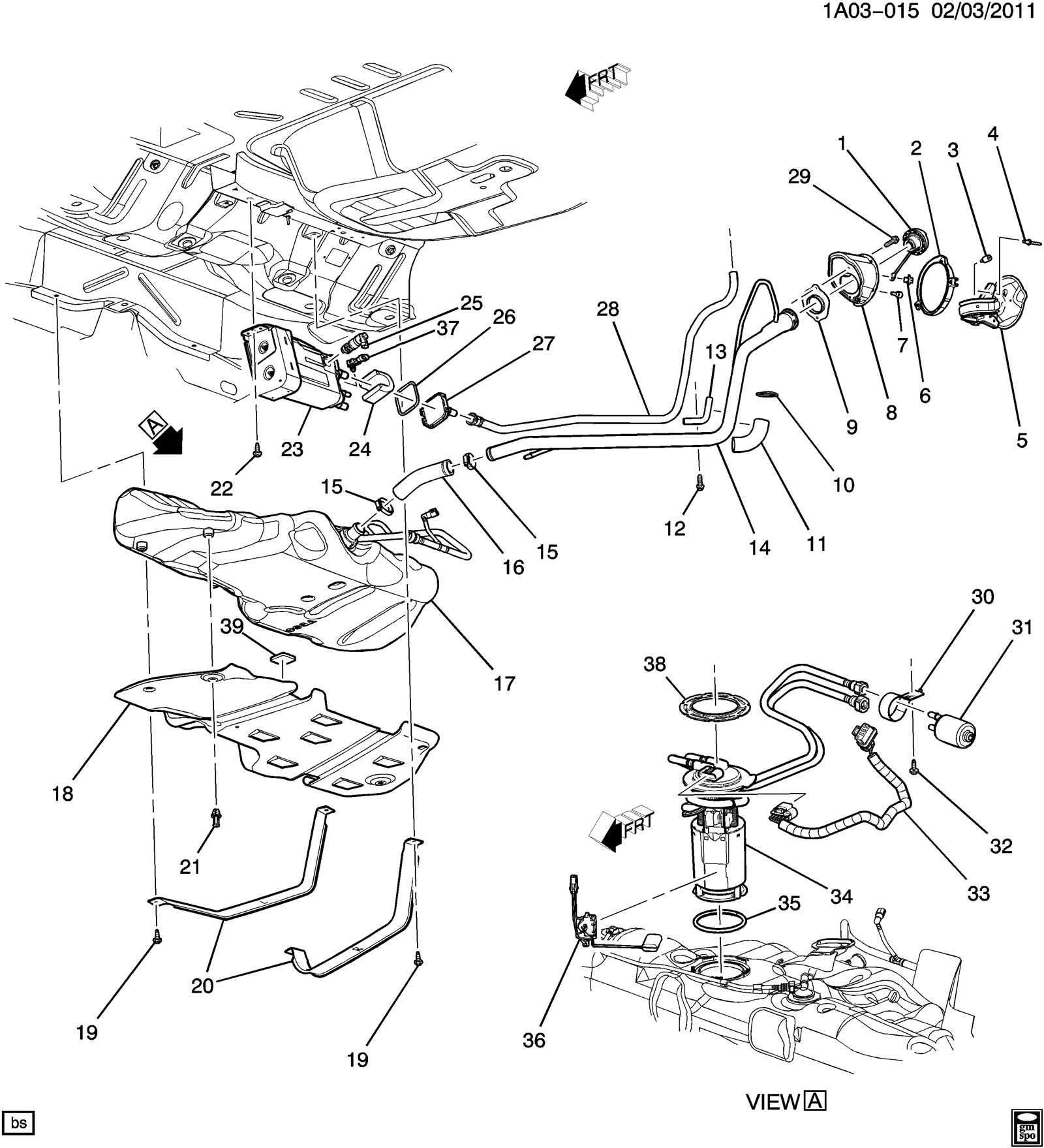

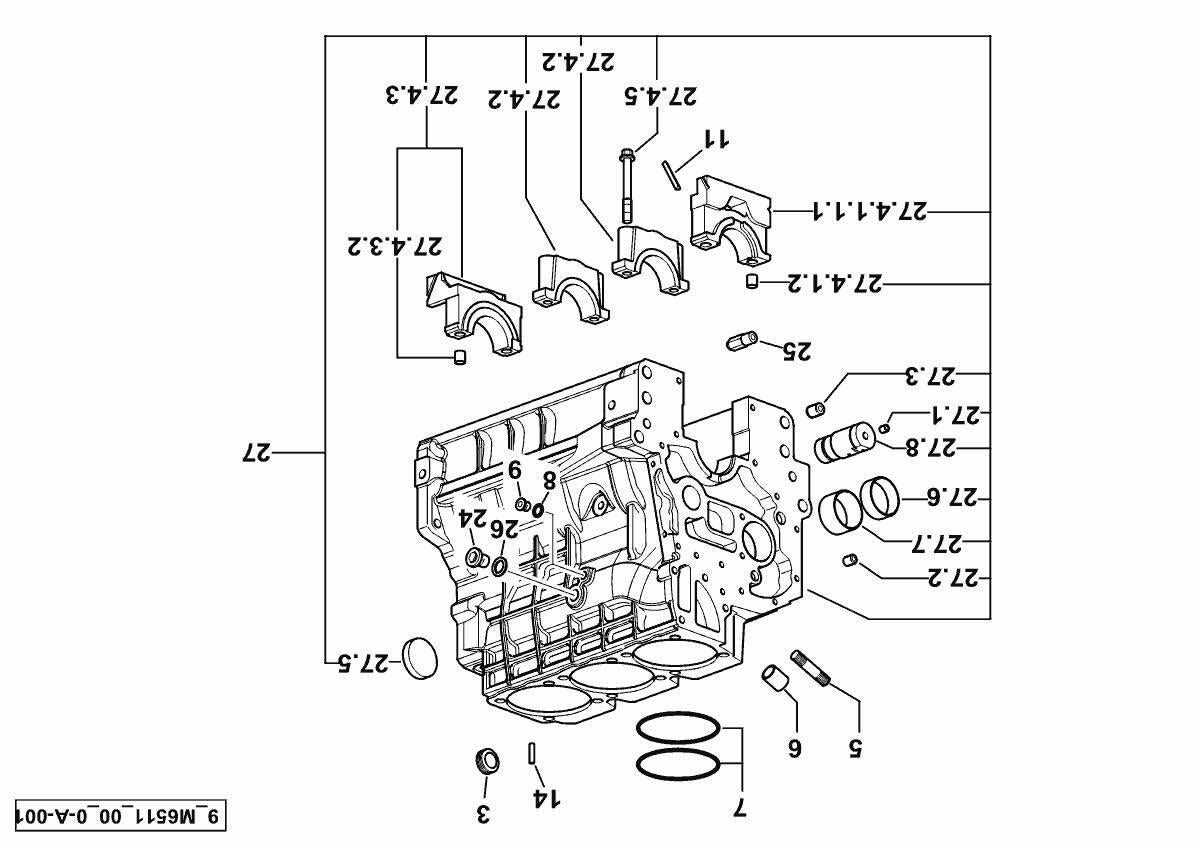

Visual Cues for Identification

One of the easiest ways to identify specific sections of a tool is through visual inspection. Many components are designed with distinct shapes, sizes, and markings that make them easy to differentiate. Look for part numbers, labels, or any unique features that could indicate the role of each element. A thorough inspection will also help you spot signs of damage, wear, or corrosion that may suggest an underlying issue.

Using Manuals and Reference Guides

If visual identification proves challenging, reference guides and manuals can be invaluable. These resources often provide detailed drawings or lists of components, each labeled for easy recognition. By cross-referencing the visual appearance of a part with the guide, you can quickly pinpoint the exact item you’re looking for, reducing the chance of error during repairs.

Essential Tools for Effective Tool Maintenance

Proper upkeep of your equipment requires a set of reliable tools that help perform various maintenance tasks. Whether it’s cleaning, tightening screws, or replacing worn-out components, having the right tools ensures that each job is done accurately and efficiently. Using quality instruments not only simplifies repairs but also reduces the risk of damaging the tool during maintenance.

Basic Hand Tools for Maintenance

For routine tasks such as tightening, adjusting, or cleaning, a set of basic hand tools is essential. A good screwdriver set, pliers, and wrenches are often all that’s needed for most maintenance jobs. These tools allow you to disassemble parts with precision, making it easier to replace or inspect internal elements without causing unnecessary strain on the tool itself.

Cleaning and Lubrication Equipment

To maintain peak performance, regular cleaning and lubrication are crucial. Tools like brushes, compressed air canisters, and lubricants ensure that moving parts remain free of debris and are properly maintained. Keeping these components clean and lubricated prevents premature wear, reduces friction, and extends the lifespan of the tool, ensuring it functions as intended for a long time.