When it comes to maintaining outdoor tools, having a clear understanding of their internal components is crucial for ensuring longevity and optimal performance. Proper knowledge of the various elements that make up your device can simplify repairs, reduce downtime, and enhance overall efficiency. This guide will walk you through the essential parts, providing you with a better grasp of how everything functions together.

Familiarizing yourself with the key components allows you to quickly identify any issues and take the necessary steps to address them. From routine maintenance to troubleshooting, a well-organized structure helps in making informed decisions. A closer look at the individual pieces ensures you don’t miss any critical aspects during upkeep.

Understanding the assembly of these tools also empowers you to perform minor repairs on your own, saving time and money. The clearer the breakdown of each segment, the easier it becomes to maintain and extend the lifespan of your equipment. With the right approach, you can tackle any problem that may arise with confidence.

Understanding the Equipment’s Internal Components

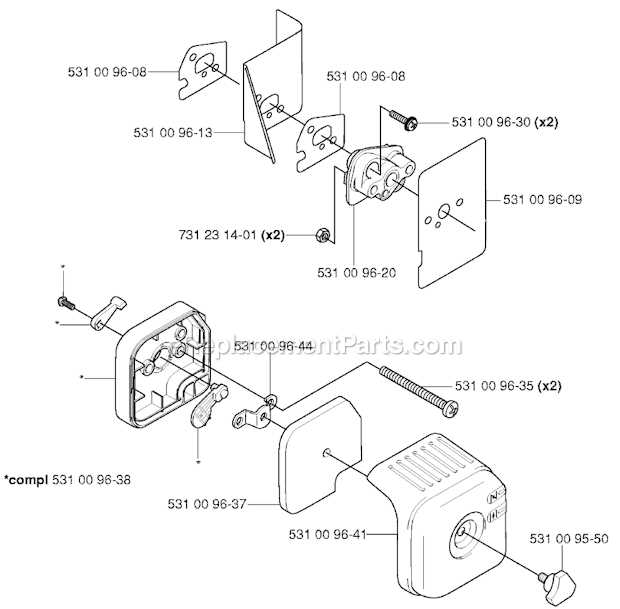

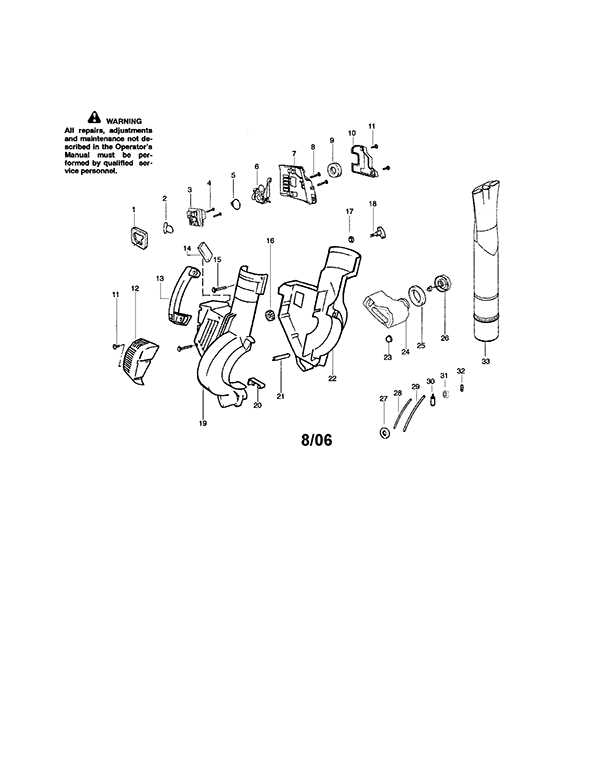

To ensure that outdoor tools operate efficiently and last for a long time, it’s essential to have a solid understanding of their internal structure. Each device is made up of various components that work together, and knowing their function can help prevent problems and facilitate easy repairs. This section breaks down the core elements that make up your equipment and explains their roles in the overall system.

Key Elements of the Device

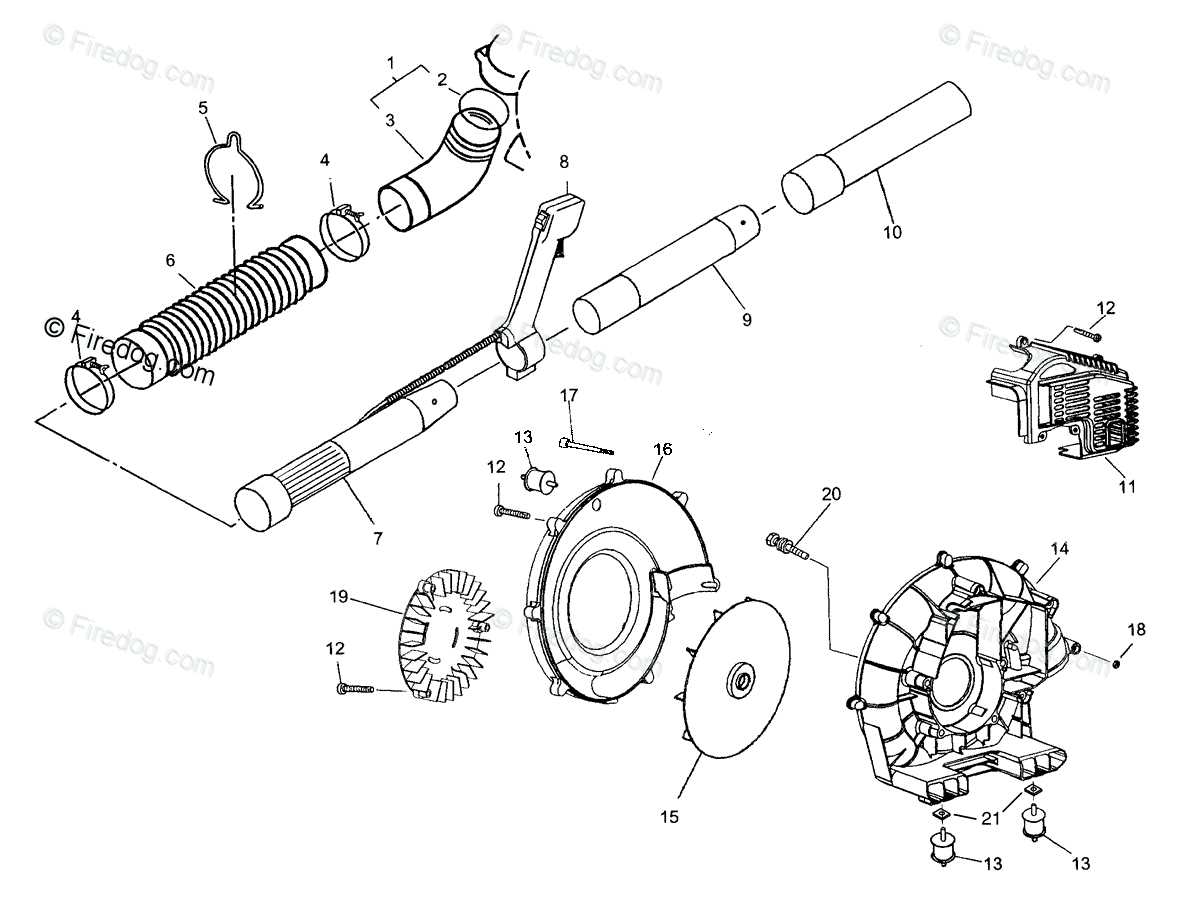

The main elements include the motor, fan, and air intake system, all of which are vital for the tool’s performance. The motor drives the fan, which generates airflow for effective operation. Regular checks on these key components ensure that they remain free from debris and damage. Understanding their placement and function allows you to spot issues early and keep everything running smoothly.

Maintenance and Troubleshooting Tips

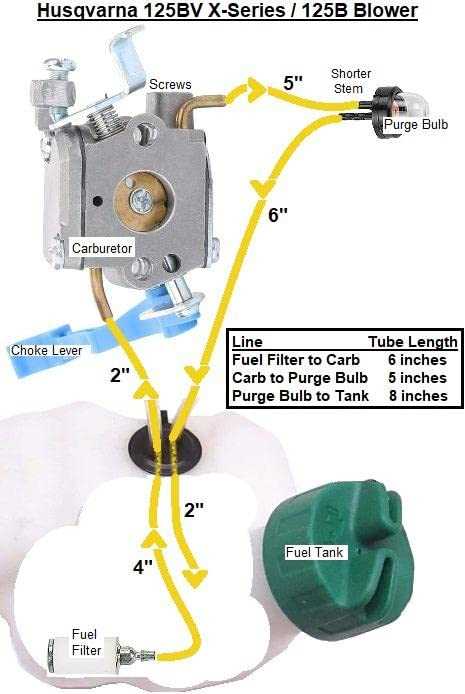

Routine maintenance is important to avoid wear and tear on critical elements. Regularly cleaning the air filter, checking for clogs in the airflow system, and inspecting the motor are simple tasks that can extend the life of your equipment. Additionally, knowing how to replace worn-out components, such as the spark plug or fuel lines, can save you time and reduce the need for professional repairs.

Being familiar with the structure also helps in troubleshooting. If the device isn’t performing as expected, knowing what each part does can guide you in diagnosing the issue quickly. Understanding the overall system ensures you are prepared for minor repairs or adjustments that may arise during regular use.

Identifying Key Components of the Blower

Understanding the essential components of your outdoor equipment is crucial for effective maintenance and troubleshooting. Each device is made up of several parts, each with a specific function that contributes to the overall performance. By knowing these elements, you can easily identify problems and address them quickly, ensuring your equipment runs efficiently for a long time.

Some of the primary components to focus on include the motor, airflow system, and fuel components. The motor drives the fan, which is responsible for generating the airflow needed for the tool’s operation. Fuel lines and filters are also essential, as they ensure that the machine gets the right fuel mixture for optimal performance. Knowing where these components are located and how they interact with each other helps you perform quick inspections and keep your equipment in good working order.

How to Maintain Your Outdoor Equipment

Proper maintenance is essential to keep your outdoor equipment in top condition, ensuring it performs well over time. Regular care prevents wear and tear, reduces the risk of malfunction, and extends the lifespan of your tools. By following a simple maintenance routine, you can keep everything running smoothly with minimal effort.

Routine Maintenance Tasks

- Clean the air filter regularly to prevent clogging.

- Inspect the motor for any signs of damage or debris buildup.

- Check the fuel system for leaks or blockages.

- Ensure the spark plug is clean and in good condition.

- Examine the cooling system to prevent overheating.

Tips for Preventing Common Issues

Taking simple steps can help prevent common problems and ensure the tool functions properly. For instance, always use the recommended fuel mixture and avoid storing the equipment with fuel inside. Regularly check all the connections to ensure they are tight and free from wear. With a little attention, you can avoid costly repairs and keep your tool performing at its best.