When working with a high-performance tool, understanding its structure and key elements is essential for proper upkeep and optimal functioning. A clear understanding of each section enables smoother repairs and more effective usage, ensuring your equipment lasts longer and performs better.

Knowing the individual components and their functions can greatly improve the overall user experience. Identifying issues early on and having the right approach to maintenance can prevent costly repairs and extend the tool’s lifespan.

By examining the layout and understanding the purpose of each part, users can easily troubleshoot and maintain their equipment. This guide will provide a comprehensive look at the major sections, making it easier to keep your tool in top working condition.

Understanding the Stihl HL 94 Parts

To maintain the tool effectively, it’s crucial to have a clear understanding of its key elements. Every component plays a specific role in ensuring optimal performance, and recognizing each one helps with both daily use and troubleshooting. Familiarizing yourself with the main sections and their functions simplifies repairs and upkeep.

Each part of the tool is designed with a particular purpose in mind, working together to ensure smooth operation. From the motor to the cutting mechanism, knowing how they interact with each other helps in identifying any issues early. By grasping the role of each element, you can make informed decisions when it comes to maintenance and replacement.

Proper maintenance starts with understanding the structure of the tool. A thorough knowledge of its various components allows you to spot wear and tear or malfunctioning pieces, leading to quicker repairs and preventing more severe damage over time.

How to Read the Parts Diagram

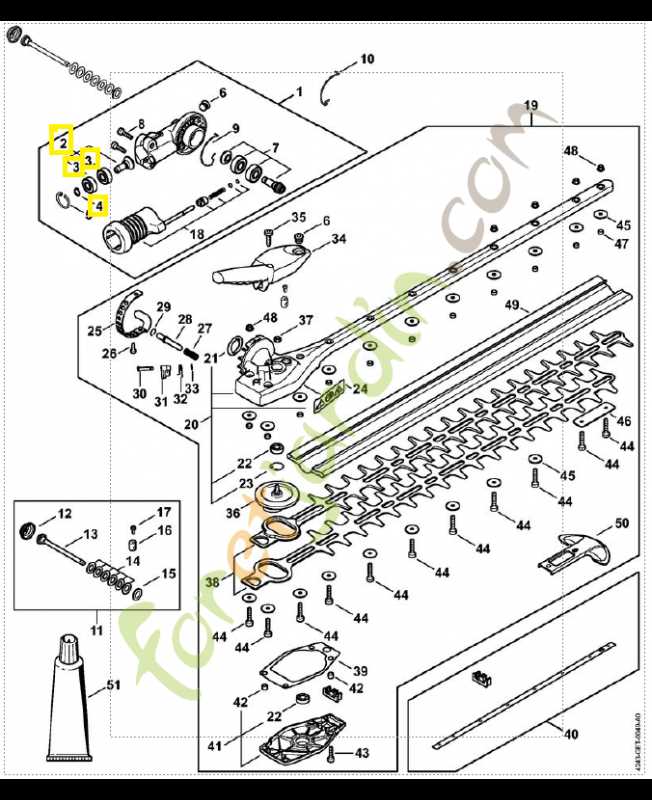

Understanding the layout of your tool’s components is essential for performing accurate repairs and maintenance. The visual representation of the structure provides a clear overview of how each section fits together and how they interact. Reading this guide carefully will enable you to identify specific elements easily.

Each section of the visual guide is labeled to correspond with individual parts, showing their position within the overall system. By focusing on these labels and following the lines connecting each piece, you can trace the path of each element and understand its relationship with others. This method is helpful when searching for the source of a malfunction or when making replacements.

Pay close attention to the symbols and numbers that accompany each component. These often indicate important details, such as size, model compatibility, or assembly order. Understanding these identifiers will allow you to match the correct piece with the visual representation, ensuring a more efficient and accurate repair process.

Common Issues and Replacement Parts

Even the best equipment can face occasional issues over time. Recognizing common problems early and knowing which elements need to be replaced can save both time and money. By understanding frequent malfunctions, users can ensure that their tools remain functional and reliable for years.

Frequent Problems and Symptoms

One of the most common issues is reduced performance, which could be a sign of wear in key components like the motor or cutting system. Often, you may notice a decrease in efficiency, unusual vibrations, or difficulty in operation. Identifying these signs early can help you pinpoint the malfunctioning part before it worsens.

When to Replace and What to Look For

If specific elements show signs of extreme wear, such as cracks, corrosion, or damage from heavy use, it’s important to replace them immediately. Regular inspection and being proactive in replacing worn parts can prevent breakdowns and ensure smooth operation. Keep an eye on high-wear areas like the drive system and blades, which often require the most attention.