Understanding the structure and functioning of garden machinery is crucial for efficient maintenance and repairs. Whether you’re dealing with a tiller, cultivator, or other similar tools, being able to identify individual components ensures smooth operation and longevity. This guide will help you navigate the various elements involved in such machines and provide you with useful insights for proper upkeep.

By familiarizing yourself with the key sections and mechanisms, you’ll be able to troubleshoot common issues, replace damaged parts, and optimize performance. A well-maintained machine can save time and effort, making it an indispensable asset for any garden enthusiast or professional landscaper.

Effective identification of each component and understanding its role are the first steps toward proper maintenance. With the right approach, you can extend the life of your equipment and ensure it remains in top working condition throughout the seasons.

Understanding Garden Machinery Components

Every gardening machine consists of various elements that work together to achieve optimal performance. To properly care for such tools, it’s essential to know the role of each individual component and how they interact. Recognizing the main sections of the equipment can help you identify potential issues and streamline repair efforts.

For efficient operation, the engine, gearbox, blades, and other vital components must be in proper condition. Each part has a specific function, whether it’s powering the machine, facilitating movement, or breaking up soil. Understanding these functions allows for more informed decision-making when it comes to maintenance and troubleshooting.

Regular inspections of key areas such as belts, sprockets, and tines ensure that the machine remains in good working order. Knowing how to identify when certain components need attention can save time and prevent costly repairs in the long run. Proper knowledge of these elements ensures your gardening tool continues to perform at its best.

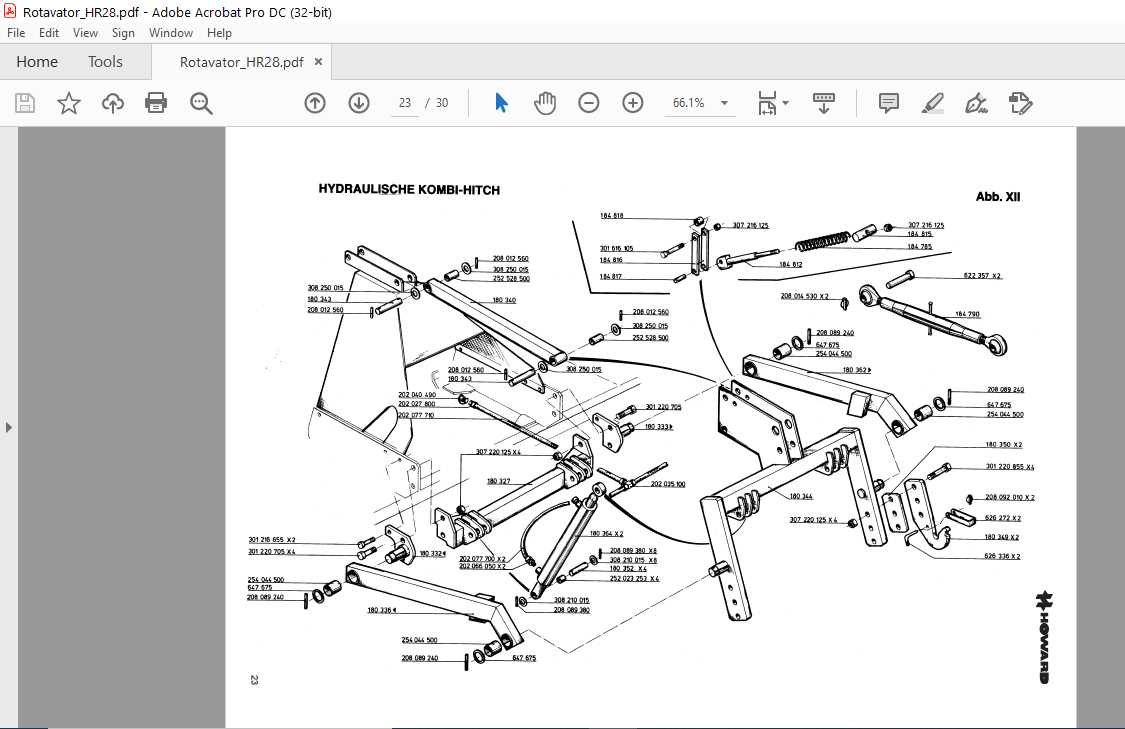

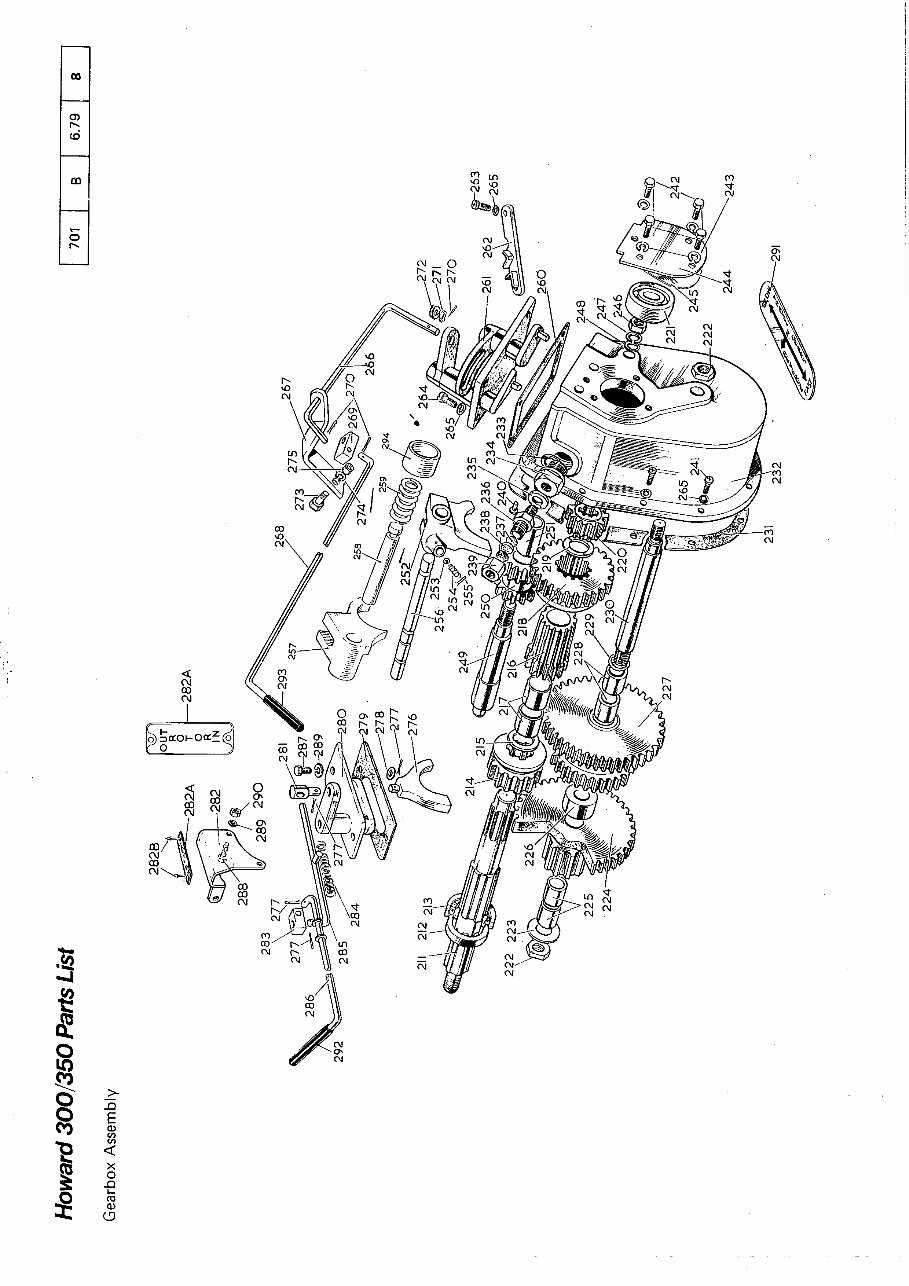

How to Use a Parts Diagram Effectively

Understanding how to read and utilize an equipment breakdown is crucial for any maintenance or repair task. This visual representation helps to identify each element within the machine and understand its relationship with others. By using it properly, you can easily locate specific components and ensure that you address the right areas when troubleshooting or replacing parts.

Identify Key Sections

Start by focusing on the primary parts that need attention. A breakdown usually highlights the major sections, such as the motor, transmission, or cutting elements. Recognizing these sections first will give you a clearer understanding of the overall structure. This will help you narrow down your focus during repairs or when replacing worn-out pieces.

Match with Physical Components

Once you’ve identified the necessary components on the breakdown, compare them to the actual parts in the machine. Ensure that each component’s shape, size, and placement align with what’s depicted. This is especially important when ordering replacements, as the right fit is essential for proper function. Using a breakdown ensures accuracy and efficiency when performing any repairs or upgrades.

Properly utilizing this visual guide reduces confusion and speeds up the repair process. It ensures that each step is performed correctly, saving both time and resources in the long term.

Common Garden Tool Repairs and Replacements

Like any piece of machinery, garden tools require regular maintenance to ensure they continue to function effectively. Over time, various components can wear out or become damaged due to continuous use. Identifying common issues and knowing how to fix or replace the faulty parts can save you time and money, while keeping your equipment running smoothly.

Worn Blades and Tines

One of the most common issues with garden tools is worn or damaged cutting elements. Blades and tines are responsible for breaking up the soil, and after extensive use, they may lose their sharpness or become bent. Replacing these components is essential for maintaining the efficiency of the machine. Make sure to choose the correct size and type of replacement to ensure proper functionality.

Engine and Transmission Troubles

Another frequent issue involves the engine or transmission. If the equipment starts to lose power or struggles to move, the cause could be an issue with the motor, belts, or gears. Inspecting and replacing worn-out belts, checking the gearbox, and ensuring proper lubrication can solve these problems. In more severe cases, the engine itself may need to be repaired or replaced.

Regular maintenance and addressing these common issues as soon as they arise can extend the lifespan of your garden equipment. Proper care ensures that the machine performs at its best and avoids costly repairs in the future.