Maintaining your outdoor power tool requires a clear understanding of its individual components. Knowing how each part fits into the larger system helps ensure that everything runs smoothly, enhancing both efficiency and longevity. This guide will walk you through the key elements and offer insights into how they function together.

By familiarizing yourself with the layout and structure of your machine, you can perform maintenance tasks with greater ease and precision. Whether you’re looking to replace a specific component or troubleshoot an issue, having access to a well-organized reference can save time and reduce errors.

Identifying essential components and knowing their role is critical for effective repairs. This guide provides a detailed overview to help you make informed decisions, ensuring that your equipment stays in top working condition for years to come.

Understanding the Stihl BR800X Components

Every outdoor power tool is made up of several key components that work together to ensure optimal performance. Recognizing how each individual element contributes to the overall functionality is essential for both routine maintenance and troubleshooting. With this understanding, you can identify areas that may need attention or replacement without unnecessary confusion.

Each piece has a specific role, whether it’s aiding in the tool’s operation, facilitating ease of use, or ensuring safety during operation. Familiarity with the structure of these elements allows users to approach maintenance tasks more effectively and address issues swiftly, reducing downtime.

For anyone looking to maximize the life of their machine, knowledge of the core components is vital. This section delves into the essential parts and their functions, offering a closer look at what makes your tool run smoothly.

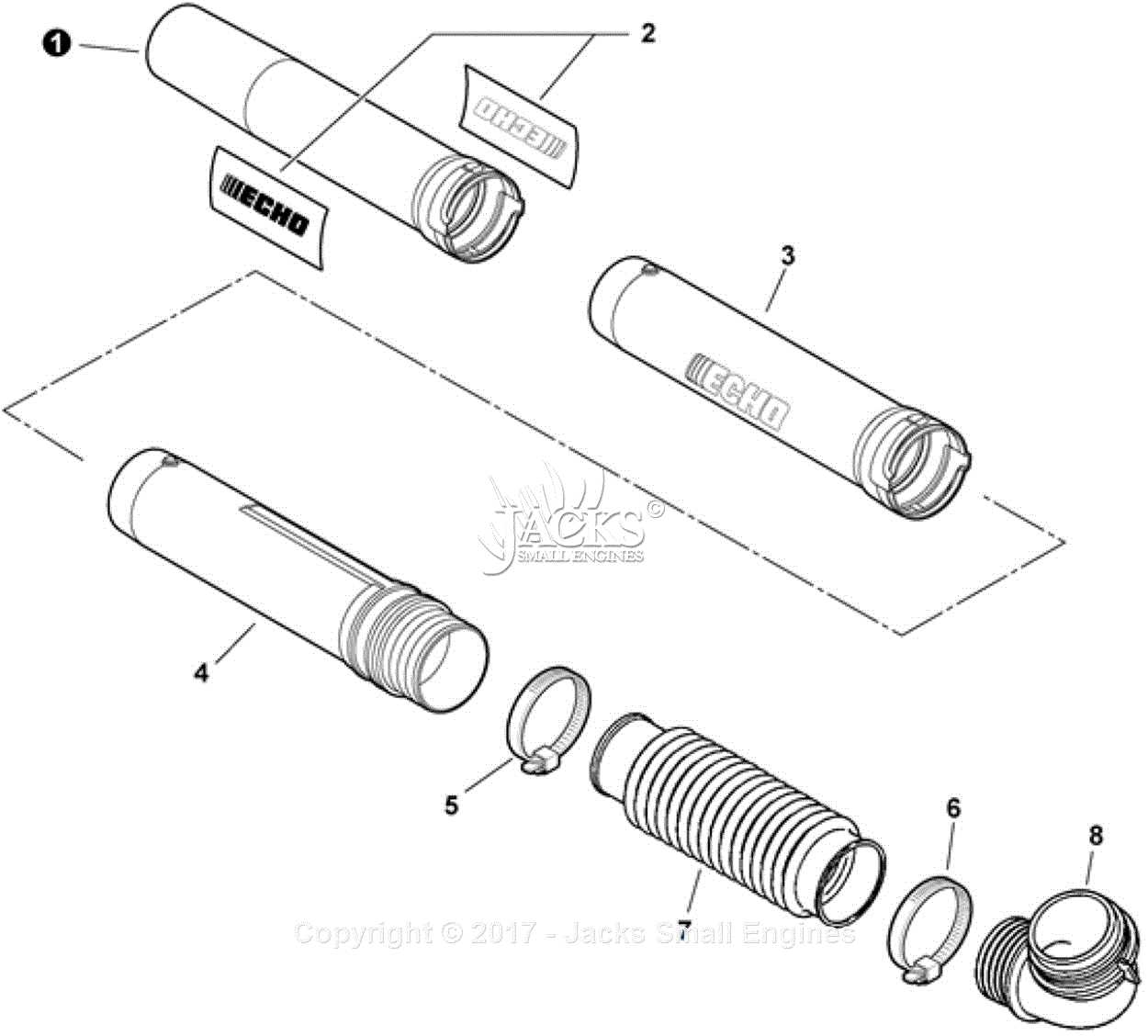

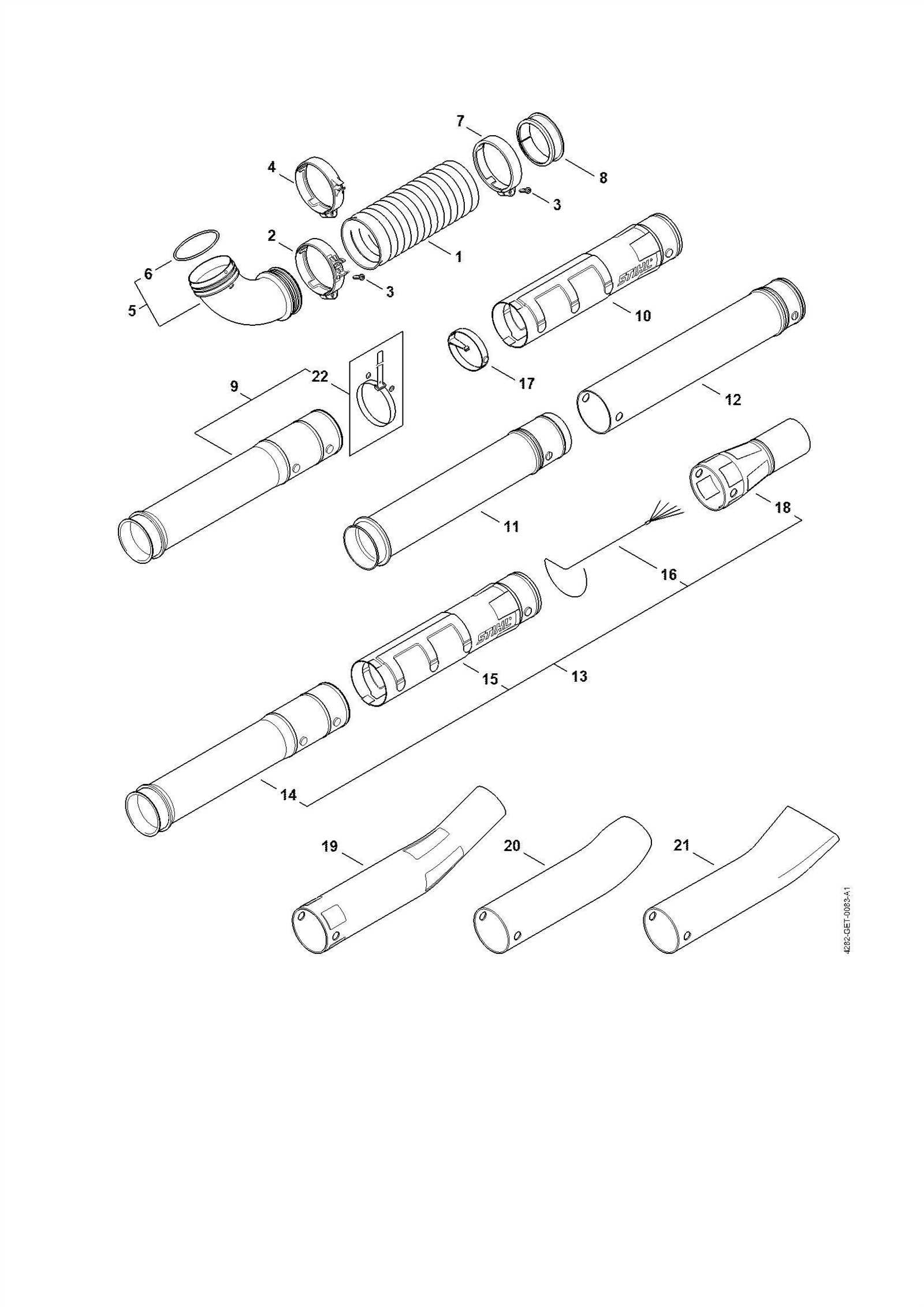

How to Read the Parts Diagram

Understanding a visual breakdown of your machine is crucial for identifying and locating its various components. These diagrams offer a clear and organized view, helping you easily navigate the internal structure. By interpreting this layout, you gain insight into how each part connects and functions within the overall system.

To read these visuals effectively, focus on the labeling and numbering system that typically accompanies the image. Each section is marked with identifiers, which correspond to detailed descriptions or part numbers. This makes it easier to match the visual elements with actual components when you need to replace or repair them.

Being familiar with these reference guides also allows for more informed decisions when performing maintenance or troubleshooting. By learning how to navigate this type of resource, you can handle your tool with greater precision and care.

Key Parts for Stihl BR800X Maintenance

Effective maintenance relies on understanding the key components that require regular attention. These essential elements help maintain performance and ensure the longevity of your tool. Knowing which parts are most crucial allows for focused care and timely interventions, minimizing the risk of damage or malfunction.

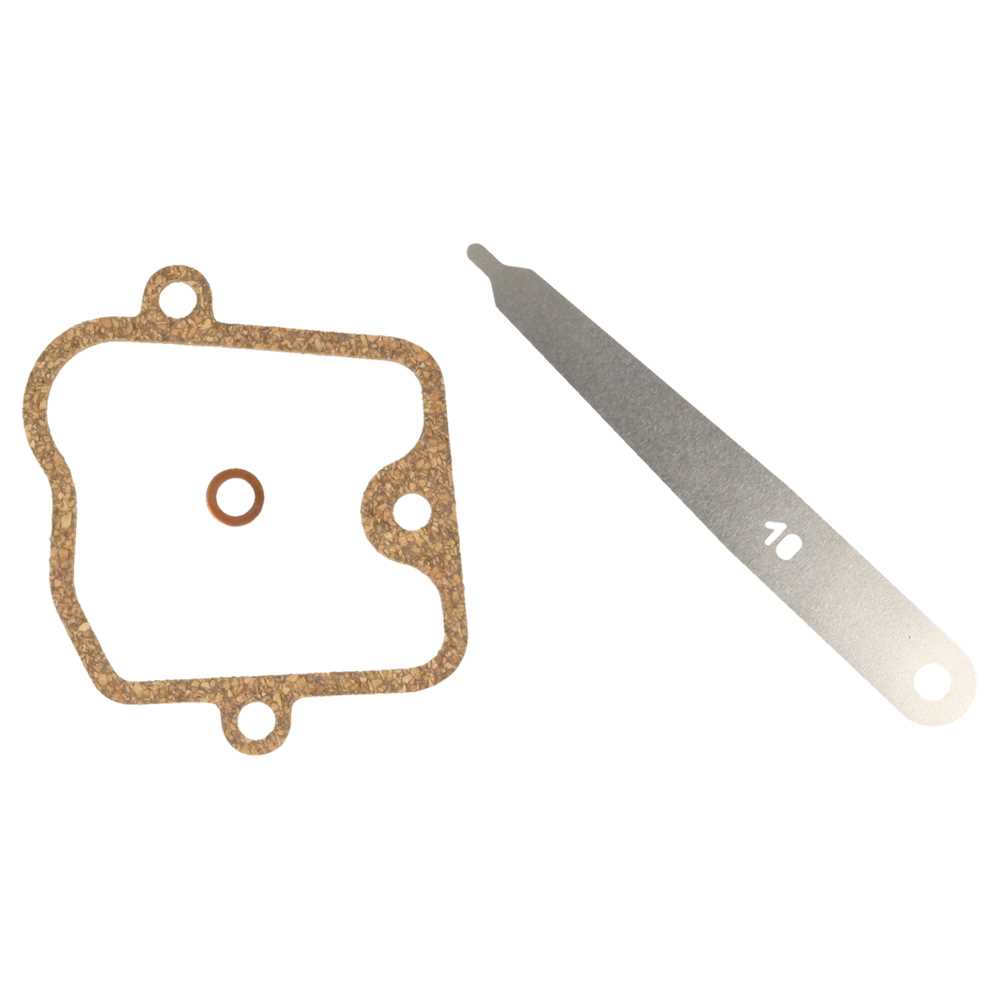

Air Filter and Engine Components

One of the most important components for regular inspection is the air filter. A clean air filter ensures the engine operates efficiently by allowing proper airflow. Regularly cleaning or replacing the filter prevents dust and debris from entering the engine, which can cause long-term damage.

Fuel System and Spark Plug

The fuel system, including the fuel lines and spark plug, plays a vital role in maintaining engine performance. Over time, fuel lines can deteriorate, and spark plugs may become dirty or worn. Ensuring these parts are in good condition helps maintain consistent power output and reduces the likelihood of starting issues.

Routine care of these parts significantly improves the machine’s reliability and efficiency. Keep them clean and properly serviced to avoid costly repairs and ensure smooth operation over time.