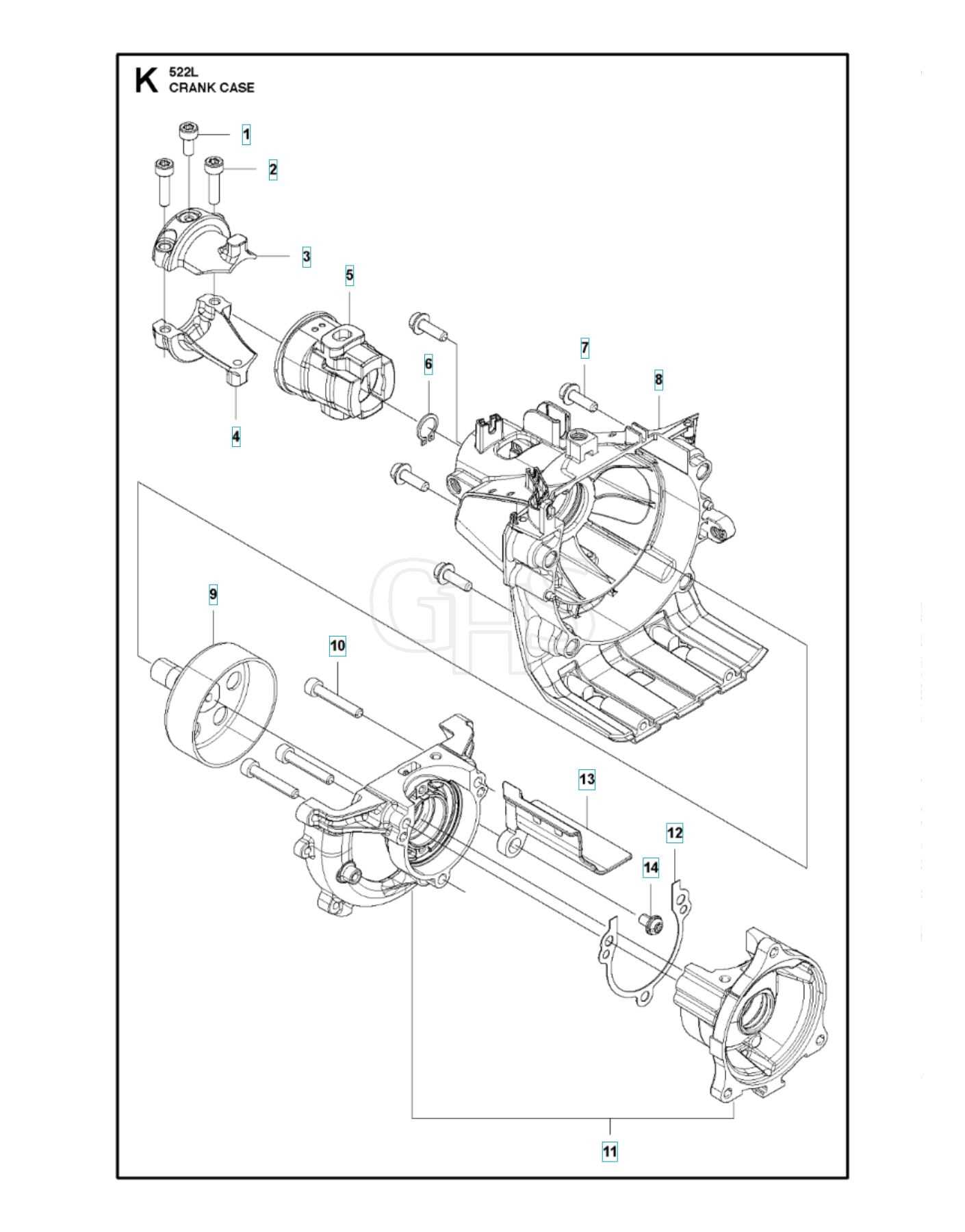

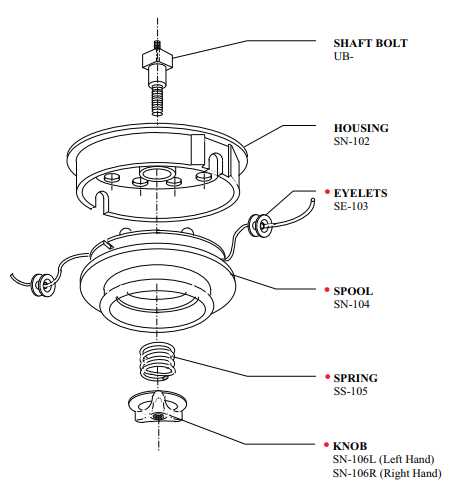

When maintaining outdoor equipment, understanding its internal structure is essential for proper upkeep and repair. A detailed layout of the various components helps in identifying the right parts for replacement and ensures smooth operation.

For users looking to perform repairs or replace worn-out elements, having a clear view of how everything fits together is crucial. A well-organized illustration of the machine’s core elements provides clarity on where each component belongs and how to access them.

By studying this guide, you will gain a better understanding of the equipment’s assembly, making maintenance tasks easier and more efficient. Accurate knowledge of individual components ensures that repairs are done effectively and without unnecessary confusion. Proper identification of each piece can save time and improve the overall performance of your machine.

Understanding Equipment Assembly Layout

Having a clear understanding of how each individual element in a machine fits together is crucial for effective maintenance and troubleshooting. A well-organized breakdown of the various components provides valuable insight into the overall structure, helping users identify which parts require attention or replacement.

By examining the layout of key components, you can quickly grasp how each element interacts with others, allowing for better-informed decisions when repairs are necessary. This knowledge can also assist in pinpointing specific areas where malfunction or wear might occur.

Comprehending the arrangement not only helps in selecting the correct replacement items but also improves the overall repair process by ensuring that the correct tools and techniques are applied. Accurate identification of each segment streamlines the maintenance workflow and minimizes errors, enhancing the longevity of the equipment.

Key Components of the Equipment Model

Every piece of machinery consists of several integral elements that work together to ensure smooth operation. Understanding the primary components allows users to better manage maintenance tasks and identify issues that may arise over time.

Among the critical elements are the engine, fuel system, and cutting mechanism, each playing a vital role in the overall performance. The engine is responsible for powering the unit, while the fuel system ensures it runs efficiently. The cutting mechanism, essential for functionality, needs regular attention to maintain its effectiveness.

Recognizing the importance of these components helps in diagnosing problems quickly and determining whether a part needs repair or replacement. Familiarity with each piece also allows for more precise adjustments, extending the lifespan and enhancing the performance of the machine.

How to Interpret the Components Breakdown

Understanding the detailed breakdown of a machine’s elements is essential for performing maintenance and repairs. This guide will help you navigate through a schematic representation of the equipment’s structure, making it easier to identify the various sections and their functions.

Step-by-Step Guide

The first step is recognizing the labels and numbers associated with each component. These identifiers link directly to specific parts that you might need for replacement or repair. Pay close attention to the groupings, as they often represent related components working in unison within the system.

Analyzing the Layout

Once you’ve identified the components, the next step is to understand their arrangement. Proper knowledge of how these parts interact allows for smoother troubleshooting and repair tasks. Additionally, interpreting the layout helps ensure that any replacement or adjustment aligns correctly with the system, improving overall machine performance.