When maintaining and repairing your outdoor power equipment, understanding the various components is essential. Every machine is made up of a variety of parts, each playing a crucial role in its functionality. Knowing how these elements fit together and work will not only help you with repairs but also ensure the longevity of your tool.

Detailed illustrations and part breakdowns are key to identifying the right components and understanding their functions. Whether you’re performing routine maintenance or fixing a malfunction, having a clear reference can save time and prevent unnecessary mistakes.

By familiarizing yourself with the structure and layout of your tool, you’ll be better equipped to make informed decisions about repairs and replacements. This guide will walk you through the essential components, helping you keep your equipment in top condition.

Understanding the Stihl FS100RX Parts

When working with outdoor power tools, it is crucial to understand the different components that make up the machine. Each element, no matter how small, plays an important role in ensuring the device functions smoothly and efficiently. Familiarizing yourself with these individual parts helps with troubleshooting and maintenance tasks, allowing for better performance and durability over time.

Main Components and Their Functions

The engine and drive system are the heart of the machine, but many other smaller components contribute to its operation. Here are some key parts that you should know about:

- Fuel System: Includes the fuel tank, lines, and carburetor, essential for delivering the correct fuel mixture to the engine.

- Starter Mechanism: Responsible for initiating the engine, it includes the pull cord and recoil spring.

- Cutting Head: This is where the line or blade is mounted, and it directly influences cutting efficiency.

- Handle and Shaft: These parts provide the framework for the tool and are crucial for control and stability during use.

Importance of Regular Maintenance

Understanding how each component functions also allows you to perform effective maintenance. Regular inspection of the machine’s key elements, such as cleaning the carburetor, checking the cutting head, and ensuring the fuel system is intact, can prevent breakdowns and prolong the tool’s lifespan.

Additionally, replacing worn-out components at the right time helps maintain the optimal performance of the equipment. Knowing the layout and role of each part simplifies the identification of problems and accelerates repair processes.

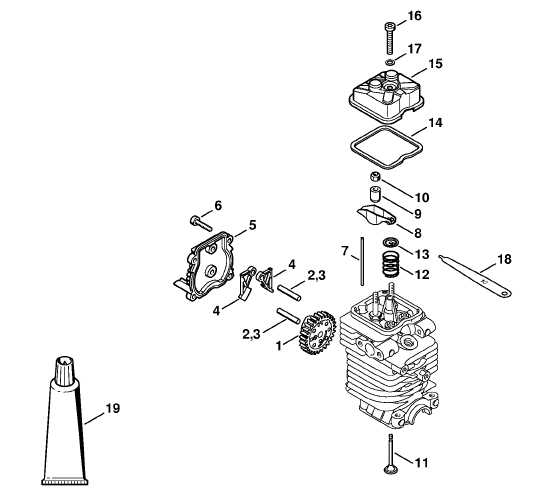

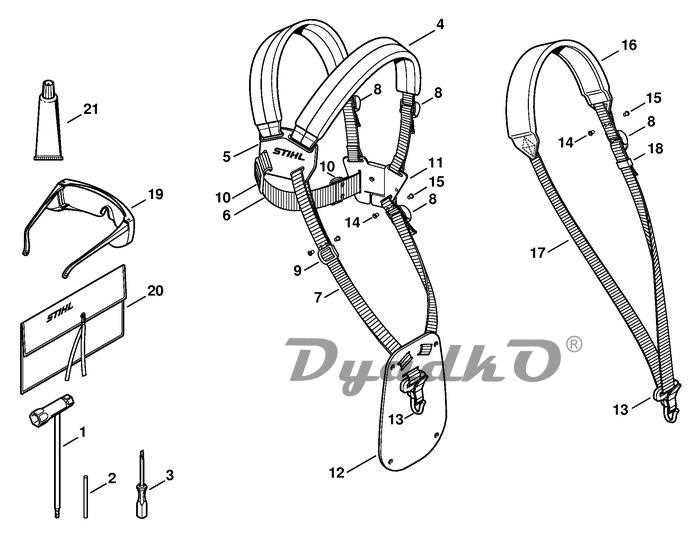

How to Read the Stihl FS100RX Diagram

Understanding a technical illustration of your outdoor power tool is essential for effective repairs and maintenance. These diagrams serve as visual blueprints, providing a detailed overview of how various components are arranged and interact within the tool. Learning how to read these visuals can greatly enhance your ability to diagnose issues and carry out replacements accurately.

The diagram typically highlights all key components, showing their positions relative to one another. It includes numbers or labels next to each part, which correspond to a parts list or reference guide, allowing you to identify specific elements and their functions within the system. By following the layout and understanding how each piece fits into the larger assembly, you can easily locate the component you need to examine or replace.

Take note of important details such as the orientation of parts, connection points, and the sequence of assembly. These will help you assemble the tool correctly after maintenance or identify any missing or damaged parts during troubleshooting.

Common Issues and Parts Replacement

Every outdoor tool experiences wear and tear over time, leading to various issues that require attention. Identifying these problems early and replacing the necessary components ensures the equipment continues to function efficiently. Some issues are more common than others, and knowing how to address them will save time and effort in the long run.

Typical Problems and Their Causes

Here are a few common issues that often arise with outdoor power tools:

- Engine not starting: This can be due to fuel system issues, clogged filters, or a faulty starter mechanism.

- Loss of power: A decrease in performance may be caused by a clogged air filter, worn spark plug, or fuel line problems.

- Damaged cutting head: Over time, the cutting head may become worn or misaligned, affecting the efficiency of the tool.

Replacing Worn or Faulty Components

Regular inspection of the tool’s main components allows you to identify damaged or worn parts. If a part is found to be defective, it should be replaced promptly to maintain optimal performance. Common replacements include the spark plug, air filter, fuel lines, and cutting head. Always ensure you are using high-quality replacement components to prevent further issues.

By understanding the typical issues and knowing how to replace the components, you can extend the life of your tool and avoid costly repairs down the road.