Maintaining your gardening equipment is essential for ensuring smooth performance and longevity. Knowing the key elements that make up your machinery allows for quicker troubleshooting and better decision-making when repairs are needed. Familiarizing yourself with each part will help you identify when something needs fixing or replacing.

In this guide, we will explore the most common components of outdoor machines, providing a clear breakdown of their functions. Understanding how each piece works together enables more effective maintenance, making your equipment run efficiently throughout its lifespan.

By learning how to read and interpret mechanical diagrams, you’ll be able to make informed choices when replacing damaged or worn-out parts. Whether you’re an experienced user or new to machine upkeep, this knowledge will empower you to take care of your tools confidently and independently.

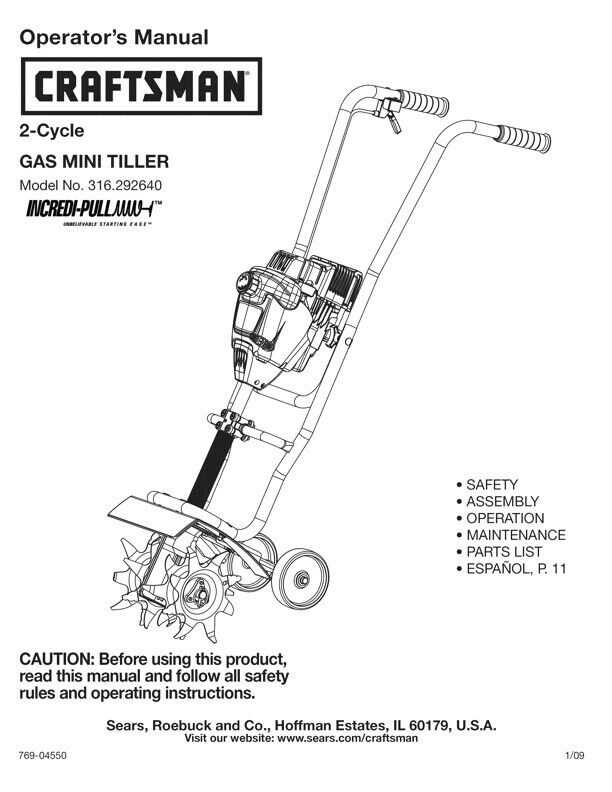

Understanding Craftsman Tiller Components

Familiarizing yourself with the various components of garden machinery is essential for maintaining its optimal performance. Each element plays a vital role in how the equipment functions, and understanding their purpose allows for better upkeep and smoother operation. This section will delve into the key components, highlighting their roles and how they contribute to the overall performance of your machine.

Key Mechanical Elements

At the heart of any outdoor equipment lies a collection of mechanical elements working together to achieve efficiency. From the engine to the transmission, each part is crucial for converting energy into useful power. Knowing where each part is located and how it interacts with others helps in troubleshooting and ensuring everything runs smoothly.

Commonly Replaced Components

Over time, certain components tend to wear out faster than others due to constant usage. Regular wear on parts such as belts, blades, and fuel systems is inevitable, but by knowing which components need attention, you can replace them promptly to avoid further damage. Recognizing these components early can save time and prevent costly repairs down the line.

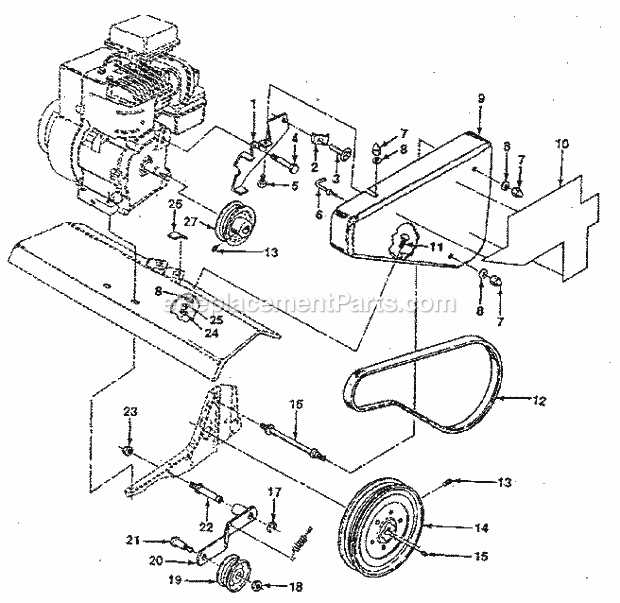

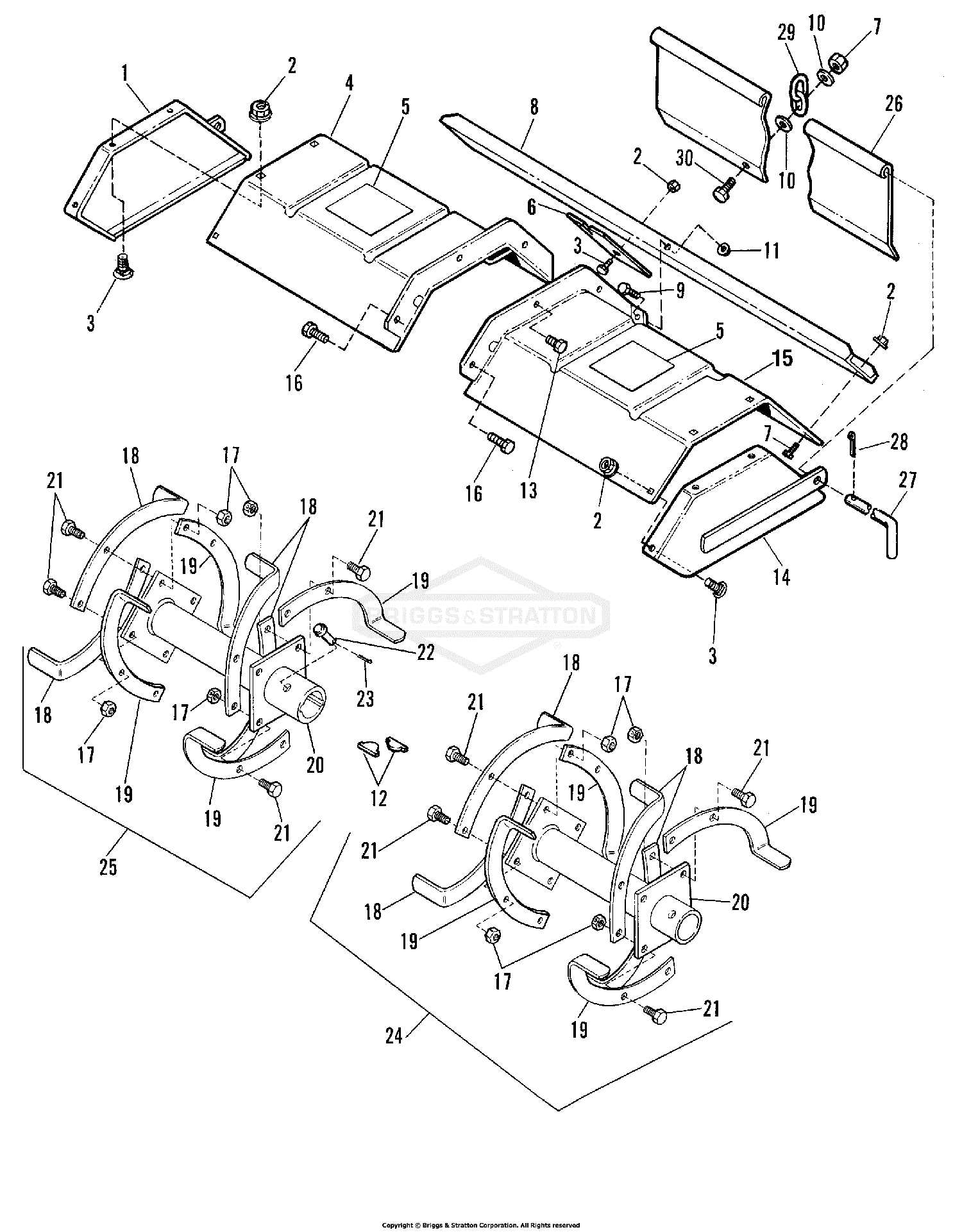

How to Read a Tiller Parts Diagram

Understanding mechanical schematics is an essential skill for maintaining and repairing your garden machinery. These illustrations provide a detailed overview of the equipment’s structure, showing how individual components fit together. Knowing how to read these visual guides simplifies the process of identifying and replacing damaged or worn-out parts.

Key Symbols and Labels

In these technical illustrations, each part is typically represented by a symbol or image, accompanied by labels that describe the function and part number. Familiarizing yourself with these symbols will help you quickly identify the correct components when sourcing replacements or performing repairs. Parts are usually numbered or categorized to make identification more straightforward.

Understanding Connections and Assembly

Another critical aspect is understanding how each component connects to others. These guides often include arrows or lines indicating how parts fit or align with one another. By following these connections, you can ensure proper assembly and avoid errors during reassembly after repairs or maintenance. Knowing how parts interrelate also helps in recognizing potential issues that could arise from improper assembly or missing components.

Common Issues and Replacement Parts

As with any piece of machinery, regular usage can lead to wear and tear, causing certain components to fail or deteriorate over time. Identifying these issues early and replacing faulty parts can extend the life of your equipment and ensure it continues to function effectively. This section highlights some of the most common problems and offers guidance on which parts are typically replaced during maintenance.

Frequent Problems with Equipment

One of the most common issues is the gradual loss of power or inefficient operation. This can stem from clogged air filters, worn-out spark plugs, or a failing fuel system. Another frequent problem is damaged blades or other cutting components, which can reduce effectiveness and make tasks more labor-intensive. It’s essential to regularly inspect these parts to ensure they’re functioning properly and to prevent further damage to the machinery.

Essential Replacements for Optimal Performance

Parts such as belts, cables, and spark plugs are commonly replaced during routine maintenance. These components are subject to constant stress and are prone to wear over time. When issues arise, replacing these elements promptly can prevent more severe damage to the machinery. In some cases, upgrading certain components can even enhance the overall performance of the equipment, ensuring it runs smoothly for longer periods.