Proper maintenance and repair of snow clearing machines require a clear understanding of their key components and how they work together. Recognizing the individual elements of these machines is essential for effective troubleshooting and maintenance. This guide will help you navigate through the complex parts, ensuring smooth operation during winter conditions.

In this article, we will provide a detailed overview of the equipment’s construction, offering insights on how each component functions. Whether you’re a seasoned operator or a beginner, knowing how to identify and manage these elements will save you time and money on repairs.

Effective maintenance starts with knowing what you’re working with. We’ll explore various diagrams and breakdowns that will make understanding these machines simpler and more manageable.

Understanding the Snow Clearing Equipment Components

Every snow removal machine consists of multiple elements that work in harmony to perform the necessary tasks. These components, though seemingly simple, have intricate designs and specific functions that ensure smooth and efficient operation. Familiarity with these parts is crucial for operators, as it helps them identify issues quickly and prevent breakdowns during critical moments.

Key Elements of the Snow Clearing Mechanism

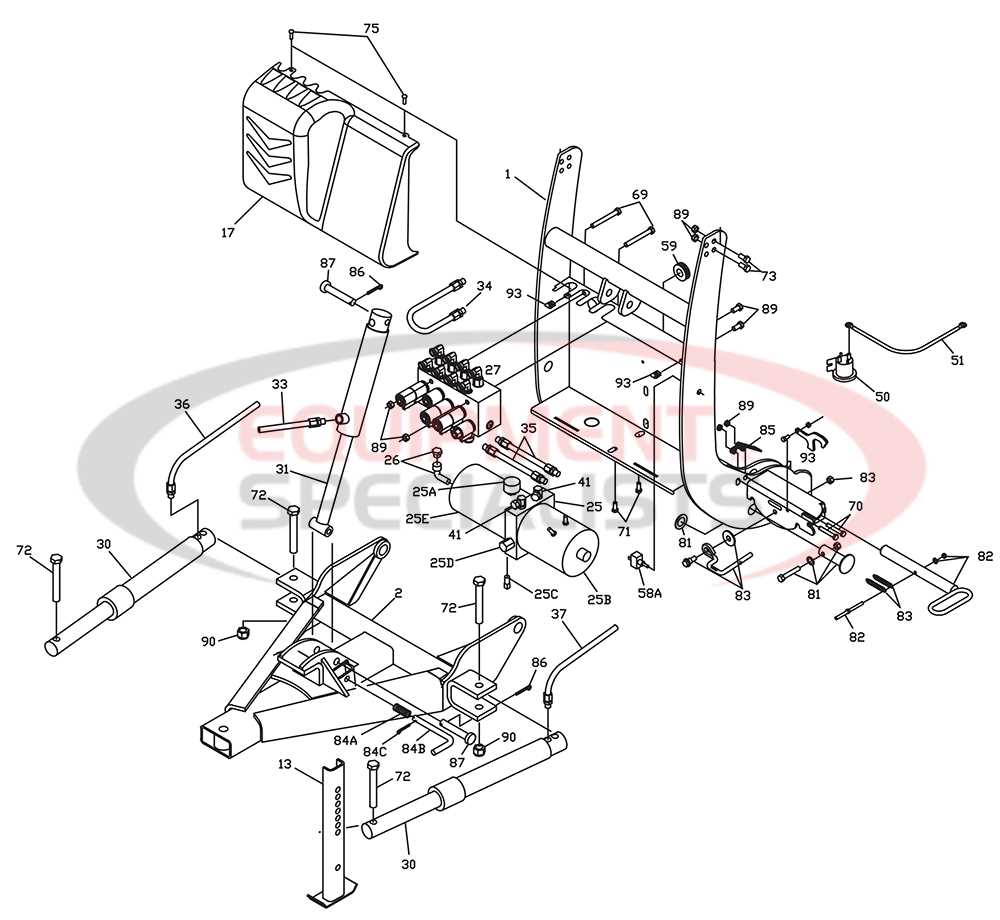

The main sections of this equipment include the lifting system, control components, and the clearing blade. Each of these elements plays a vital role in the overall performance. The lifting mechanism, for example, allows the operator to adjust the height of the blade for different snow depths, while the control system provides the ability to maneuver the device effectively in varying conditions.

Importance of Understanding Each Component

When dealing with repairs or maintenance, knowing how each individual part functions allows for faster identification of problems. Being able to pinpoint a malfunctioning section can prevent unnecessary replacements or repairs and ensure the system remains operational through the toughest conditions.

Identifying Essential Components for Repair

Effective repairs begin with recognizing the key elements that require attention. Snow removal equipment, like any complex machine, is composed of various components that play a critical role in its overall function. Understanding which parts need maintenance or replacement ensures that the system operates efficiently and prevents further damage.

To identify essential components for repair, start by familiarizing yourself with the core sections of the machine. Focus on the mechanical and electrical components that are most prone to wear. Regular inspection of these parts allows for early detection of issues, making it easier to address problems before they escalate and disrupt operations.

How to Read Snow Clearing Equipment Diagrams Effectively

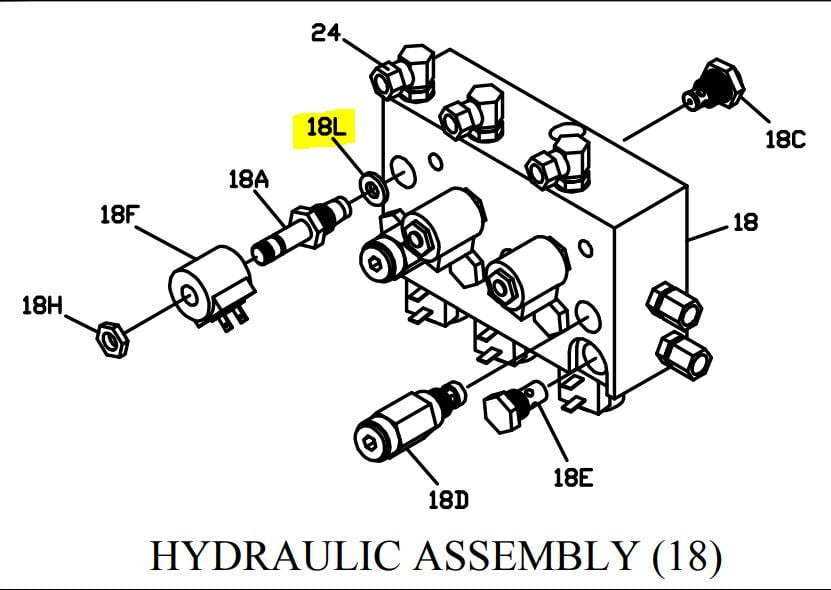

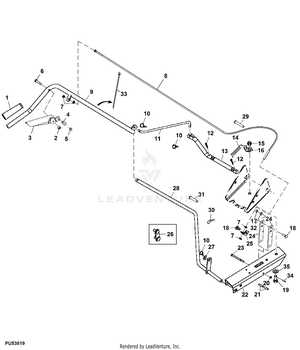

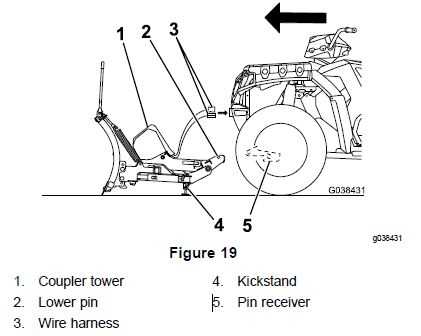

Understanding the technical illustrations of your snow removal equipment is crucial for troubleshooting and repairs. These diagrams provide a visual guide to the different components, their locations, and how they interact within the system. Knowing how to interpret these visuals correctly can save valuable time and effort when diagnosing issues.

To read these diagrams effectively, focus on the labels, symbols, and connections presented. Each part is typically marked with specific numbers or letters that correspond to parts lists or guides. By following the flow of lines and arrows, you can trace connections between components, helping you identify the source of problems more easily.

Tip: Pay attention to the sectional views, as they often provide a clearer understanding of how components fit together and where potential malfunctions could arise.