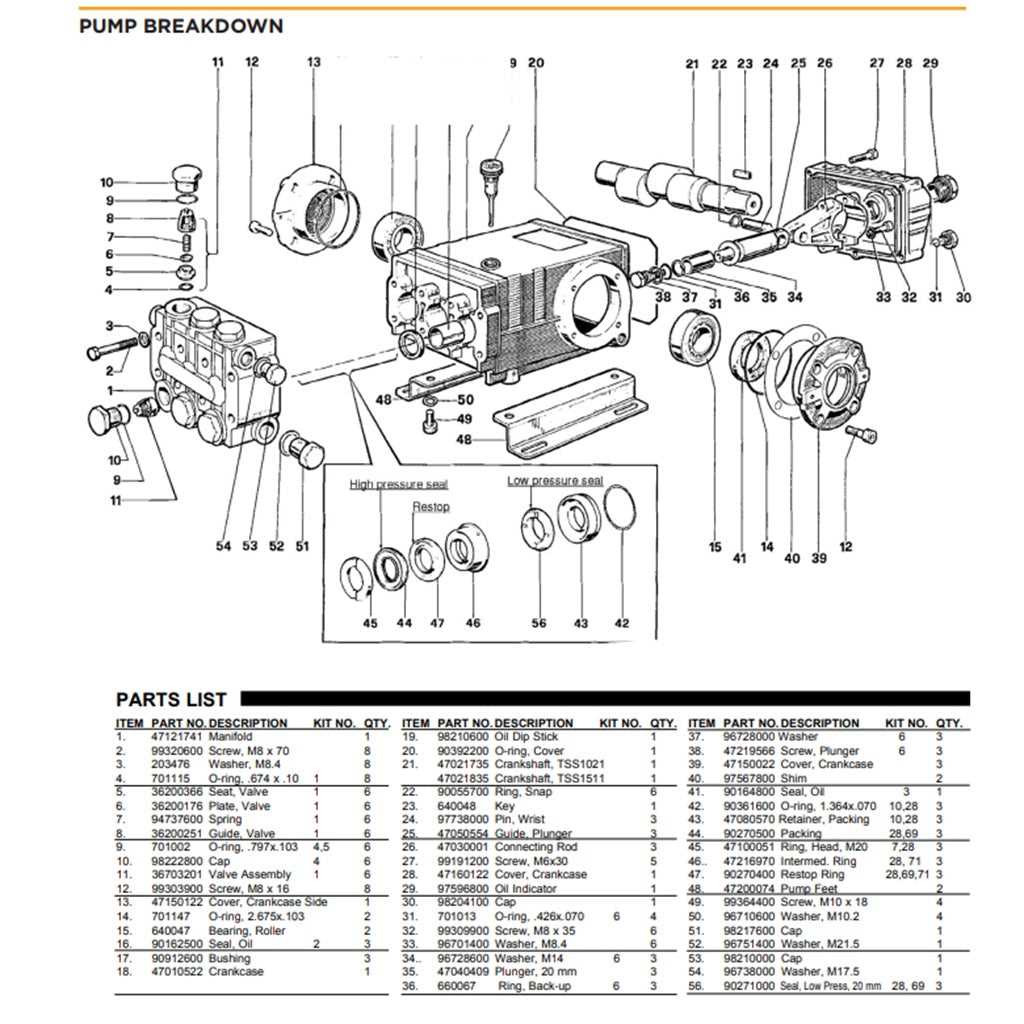

Maintaining your cleaning machine requires a thorough understanding of its structure. Each component plays a crucial role in ensuring the equipment functions efficiently. Familiarizing yourself with these elements can significantly improve performance and ease of use. Knowing how each part fits together allows for quicker troubleshooting and repairs, reducing downtime.

Identifying the various sections of the device is essential for proper maintenance. Recognizing the key components enables users to detect any issues early, preventing more significant damage. A detailed breakdown of these sections is vital for anyone working with high-performance cleaning equipment.

Proper knowledge of the equipment’s inner workings can help extend its lifespan. With the right guidance, even complex repairs become manageable, saving both time and money. Understanding how different parts interact with each other ensures a smooth and trouble-free cleaning experience every time.

Understanding the Essential Components of Your Cleaning Equipment

Every high-performance cleaning device consists of multiple elements that work together to achieve optimal results. Knowing how these individual parts contribute to the overall functionality is key to effective use and maintenance. By familiarizing yourself with the essential components, you can troubleshoot, replace, and maintain the machine more efficiently.

Main Sections of the Equipment

- Motor: The heart of the device, responsible for generating power.

- Pump: Pressurizes the water to the desired level for effective cleaning.

- Hose: Delivers pressurized fluid from the unit to the cleaning nozzle.

- Nozzle: Controls the direction and intensity of the stream.

How Understanding Components Benefits Users

- Efficiency: Identifying the correct function of each part allows for smoother operation.

- Easy Maintenance: Regular checks of components help prevent issues from escalating.

- Cost Savings: Proper knowledge reduces the need for expensive repairs and replacements.

How to Identify Key Cleaning Equipment Components

Recognizing the main elements of your cleaning system is essential for effective operation and maintenance. Each section has a unique function that contributes to the overall performance of the machine. Knowing how to identify these components allows users to troubleshoot issues, perform regular maintenance, and make necessary replacements when required.

Step-by-Step Identification Process

- Check the Manual: The first step is always to consult the user manual for specific details on each section.

- Look for Labels: Many devices have labels or stickers indicating key components, such as the motor, pump, or hose.

- Inspect the Shape: Recognizing the shape and design of each part helps in distinguishing one from another.

- Examine Connections: The way each part connects to the machine is a helpful clue for identification.

Tools and Resources for Accurate Identification

- Online Guides: There are numerous resources available online that provide detailed visuals for each component.

- Support Services: If in doubt, contacting the manufacturer’s support can ensure you correctly identify the parts.

Benefits of a Complete Component Breakdown

Having a comprehensive breakdown of your equipment’s components brings numerous advantages, especially when it comes to maintenance and repairs. By clearly understanding each section, users can perform tasks with greater accuracy and speed. This clarity helps avoid errors and ensures that the machine continues to operate at its best performance.

Improved Efficiency in Repairs

- Quick Troubleshooting: Knowing the exact function of each part helps identify issues quickly, reducing downtime.

- Accurate Replacements: With a clear visual reference, users can easily order the right replacement parts, saving both time and money.

Enhanced Long-Term Maintenance

- Preventative Care: A detailed component breakdown allows for proactive checks, preventing wear and tear from going unnoticed.

- Cost-Effective: Regular maintenance based on a complete breakdown can reduce the frequency of expensive repairs.