When working with heavy-duty farming equipment, understanding the structure and functions of its essential elements is crucial for effective operation and long-term performance. Proper identification and maintenance of each component ensure smooth operation and minimize downtime.

Knowing where each individual part fits and how they work together helps in troubleshooting and repairs. Whether it’s a mechanical failure or a need for regular maintenance, being familiar with the key elements makes a significant difference in keeping the machine in optimal condition.

In this section, we will explore a detailed overview of the crucial components involved. Familiarity with these parts and their roles will equip you to handle any necessary adjustments or repairs confidently, ensuring your machine stays functional throughout its service life. Effective care and understanding of each part can significantly extend its lifespan.

Understanding IH 1300 Sickle Mower Parts

When it comes to farm machinery, each component plays a pivotal role in ensuring the equipment functions at its best. A thorough understanding of how these elements interact can help improve overall performance and reduce the likelihood of malfunctions. Proper knowledge of the individual components is essential for both operators and technicians involved in maintenance and repair tasks.

Essential Components of the Machine

The primary function of any agricultural machine is to perform a specific task efficiently, and each element of the structure is designed to contribute to that goal. The crucial components include moving parts, structural elements, and attachments that work together to provide optimal cutting and handling capabilities. Recognizing these key elements allows for faster troubleshooting and repairs.

Common Issues and Maintenance Practices

Even with regular use, certain issues may arise over time. From wear and tear on critical components to mechanical failures, understanding the components involved makes it easier to diagnose and solve these problems. Regular inspections and maintenance are necessary to keep the machine running smoothly and prevent costly repairs. Knowing which parts need attention can save time and effort during upkeep.

How to Use the Parts Diagram

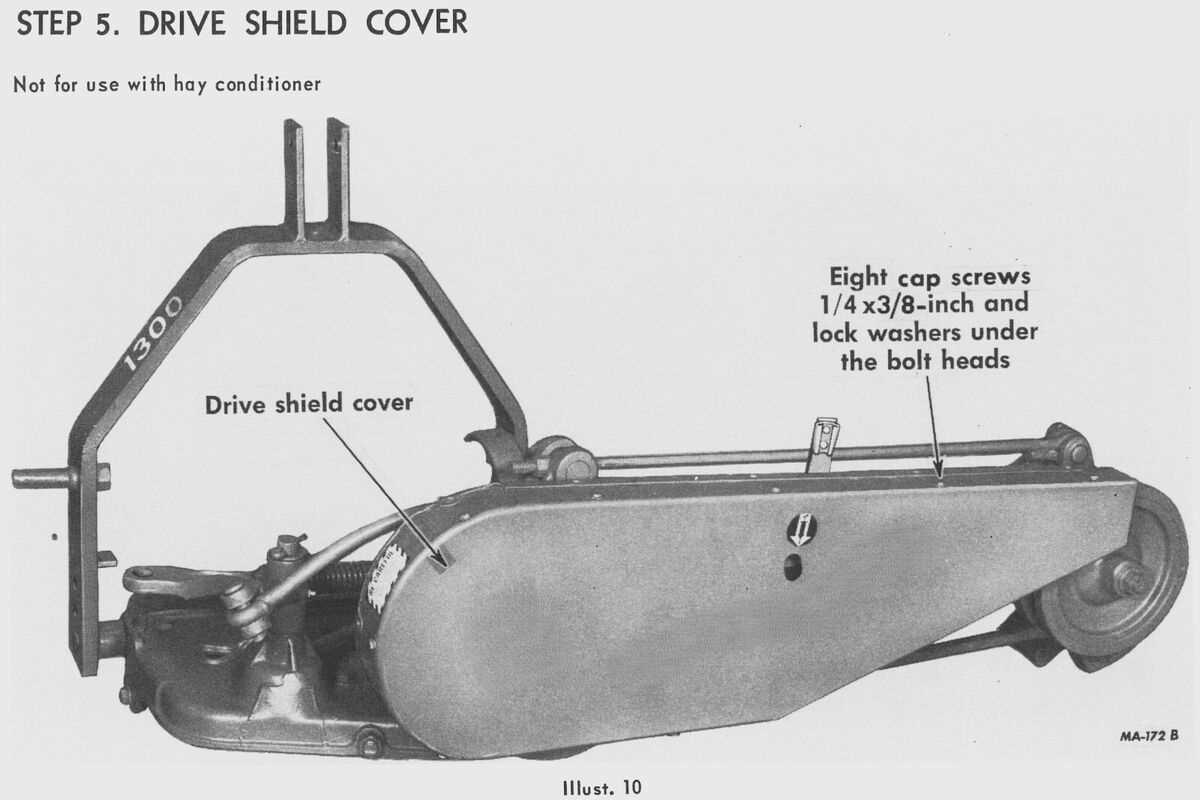

Utilizing a detailed schematic of your machinery is an essential step in understanding how each component functions within the system. This visual representation helps pinpoint specific elements, aiding in troubleshooting, repairs, and regular maintenance. By referencing this guide, operators and technicians can efficiently identify parts that need attention or replacement.

The key to effectively using the schematic is to familiarize yourself with the different sections and their corresponding components. Each part is numbered or labeled, allowing you to quickly locate the item you’re working on. Whether you’re addressing a malfunction or performing routine checks, having this visual reference simplifies the entire process.

Additionally, understanding how the elements connect and work together will provide a broader view of the machine’s overall performance. This not only helps in making repairs but also enhances preventive maintenance by identifying potential issues before they become major problems.

Common Repairs for IH 1300 Mower

Over time, even the most well-maintained machinery can experience issues due to wear and tear. Identifying and addressing these common repairs is crucial to keeping the equipment running efficiently. By understanding the most frequent problems, you can prevent costly breakdowns and ensure your machine remains in top condition.

Repairing the Cutting Mechanism

One of the most common areas that require attention is the cutting assembly. Blades and related components can become dull, misaligned, or damaged during regular use. It’s essential to regularly inspect these elements to ensure they are functioning properly. Replacement or sharpening may be necessary to maintain effective cutting performance.

Addressing Mechanical Failures

Mechanical issues can also arise, particularly in the drive system. Belts, pulleys, and gears are subjected to significant stress during operation, which can lead to wear or failure. Regular inspections and replacing worn parts before they cause more severe damage can save both time and money. Staying proactive with maintenance can help prevent major mechanical failures and keep the system running smoothly.