When working on vehicle axles, it’s crucial to understand the intricate layout of the various elements that make up this system. These crucial parts ensure smooth operation and durability, each playing a unique role in transmitting power and supporting the vehicle’s weight. With an in-depth grasp of the components, troubleshooting and maintenance become much more efficient and straightforward.

Detailed identification of these elements helps in recognizing wear and tear, improving overall vehicle performance. The correct handling of the parts is essential for safety, efficiency, and longevity. As these systems are often subjected to extreme conditions, proper knowledge allows for timely repairs and upgrades, keeping your vehicle running optimally.

Understanding the relationship between the different components provides clarity when diagnosing problems and performing repairs. Knowing where each piece fits within the assembly helps avoid confusion and ensures every part functions properly, ultimately leading to a more reliable driving experience.

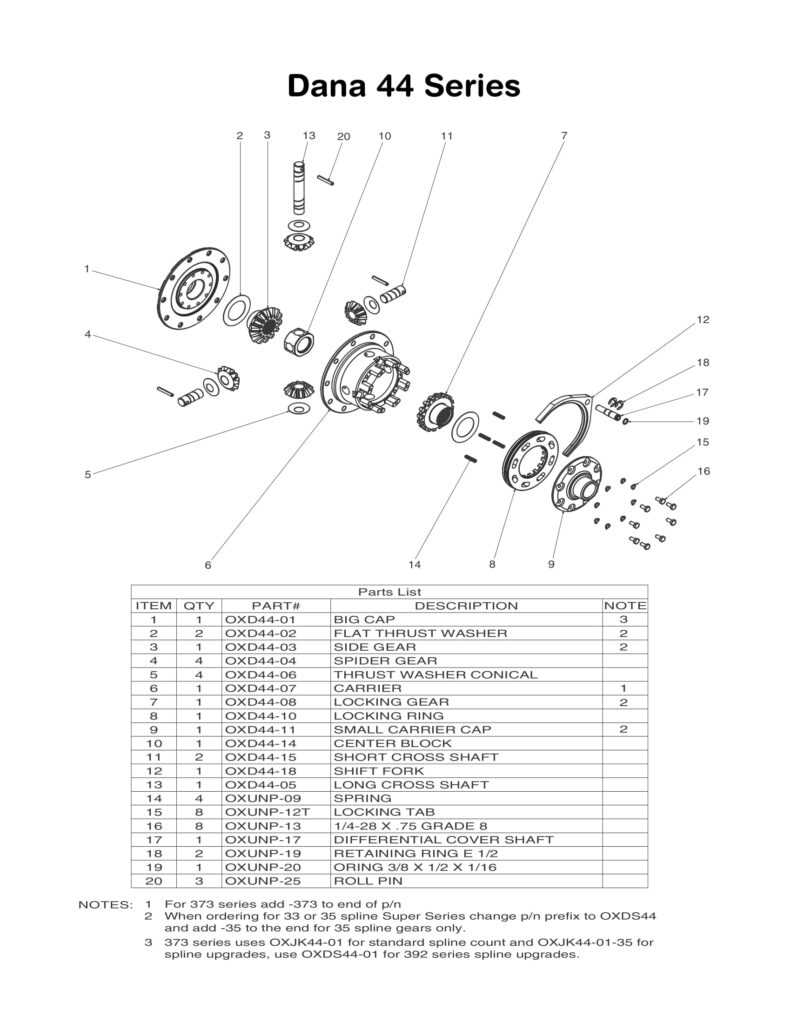

Understanding the Dana 44 Components

The axle system in vehicles consists of several interconnected elements, each serving a specific purpose. These components are vital in ensuring the proper transfer of power, smooth handling, and overall stability while driving. A deeper understanding of each part allows for better maintenance and repair practices, ensuring optimal performance over time.

The differential is one of the most critical elements, responsible for distributing power to the wheels. It enables the wheels to rotate at different speeds, particularly when turning. Another essential component is the carrier assembly, which houses the differential gears and connects the axle shafts to the wheels, supporting the system’s strength and durability.

Equally important is the ring and pinion gear set, which plays a pivotal role in adjusting the torque output and achieving the desired gear ratio. Additionally, the axle shafts themselves are responsible for transferring rotational energy from the differential to the wheels. Understanding the relationship between these components ensures a seamless operation and provides insight into how to maintain or replace any part when necessary.

Key Parts and Their Functions

Every axle assembly relies on various critical components to function efficiently. Each part has a distinct role, working together to ensure smooth operation and optimal performance. Understanding these key elements and their specific functions helps in identifying issues and carrying out effective repairs or upgrades when necessary.

The differential is one of the most important elements, allowing the wheels to rotate at different speeds, especially during turns. This function is essential for maintaining stability and preventing excessive wear on the tires. The ring and pinion gears are responsible for transferring rotational force from the driveshaft to the differential, adjusting the torque based on the gear ratio selected.

Another crucial component is the axle shafts, which carry power from the differential to the wheels, enabling them to move the vehicle. These shafts are designed to withstand the forces generated during driving and require regular inspection to ensure their durability. Together, these components make up the backbone of a reliable axle system, ensuring smooth operation and long-lasting performance.

Identifying Common Issues in Dana 44

Even the most durable axle assemblies can experience problems over time. Recognizing the common signs of wear or malfunction in the system is essential for timely repairs and preventing further damage. Knowing what to look for helps identify issues early, ensuring that the vehicle remains reliable and performs at its best.

Wear and Tear on Gears

One of the most frequent issues occurs within the gear assembly. Over time, the gears can wear down, leading to abnormal noises, such as whining or grinding, during operation. These sounds often indicate that the teeth are losing their integrity, which can lead to slipping or difficulty in transferring power effectively. Regular inspection and lubrication can help reduce wear, but once significant damage occurs, replacement may be necessary.

Axle Shaft Damage

Axle shafts are also prone to damage from heavy use. Cracks or bends in the shafts can result in vibrations or difficulty in maintaining traction. In some cases, an axle shaft may even break, leaving the vehicle unable to drive. Keeping an eye on the shafts for any signs of stress or damage and addressing any issues immediately will prevent more serious failures down the road.