When maintaining or repairing garden equipment, having a clear understanding of its structure is essential for effective troubleshooting and part replacement. Identifying individual components helps in ensuring the device operates at peak performance and reduces the risk of future issues.

Knowing how each element fits together allows for efficient servicing, saving both time and money. This guide provides an in-depth look at the various parts of your tool, enabling easy identification and maintenance procedures.

Whether you are replacing a worn-out mechanical piece or simply conducting a routine check, understanding the layout and function of the key elements can significantly improve your repair experience. Accurate identification is the first step towards a properly functioning machine.

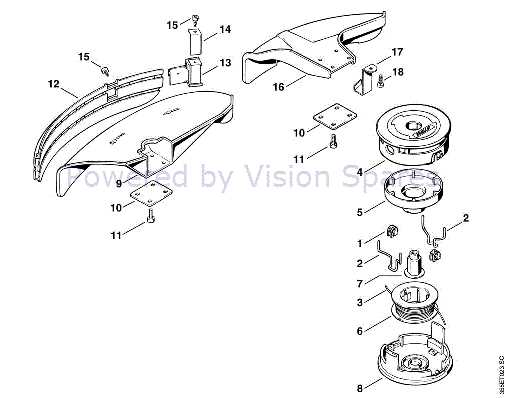

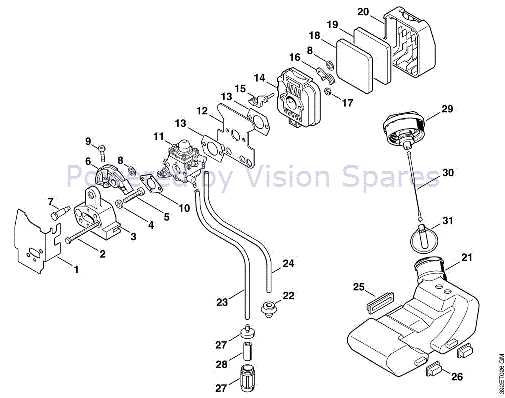

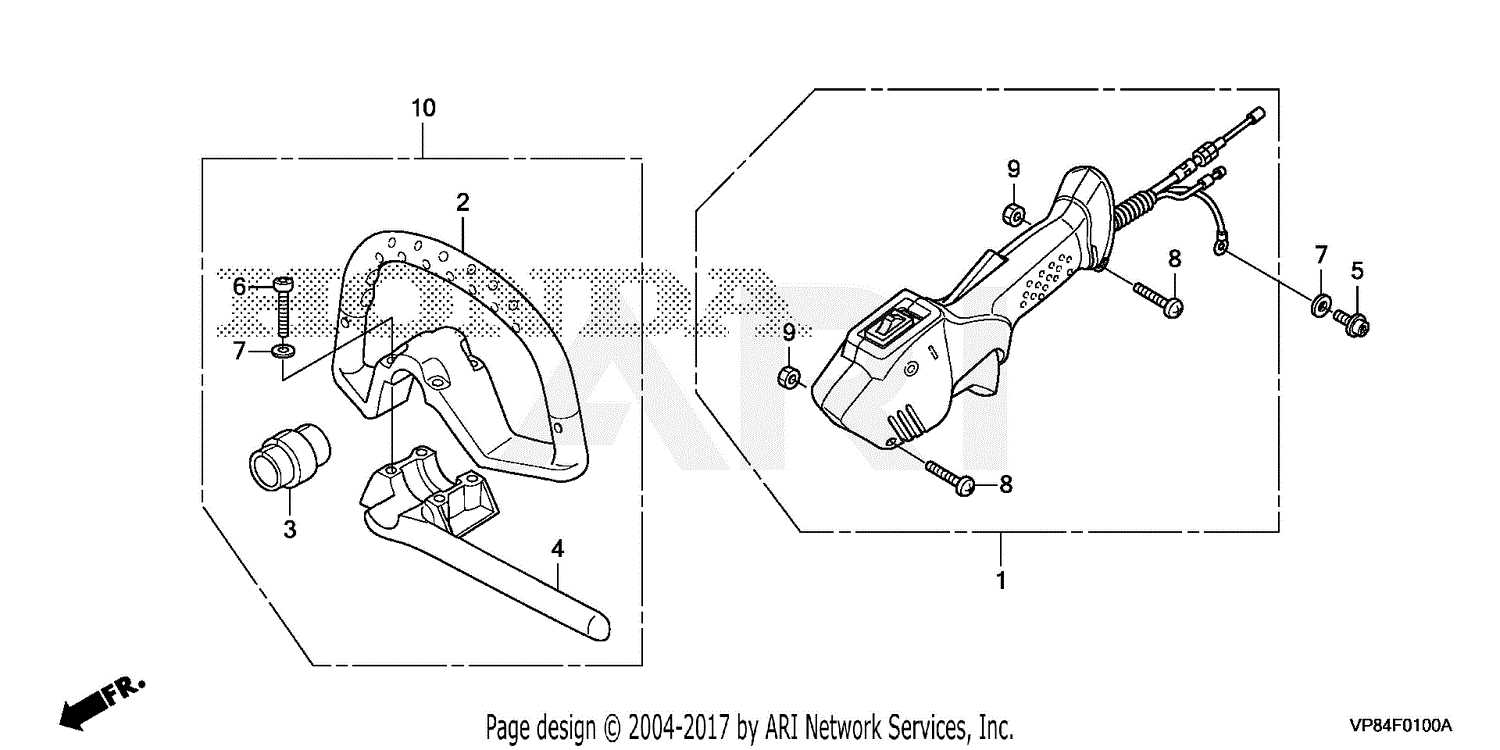

Understanding Trimmer Component Breakdown

Every tool consists of various integral elements that contribute to its overall functionality. A clear understanding of each component and its role can significantly improve maintenance efforts and prevent operational failures. This section will guide you through the main sections of your equipment, helping you identify key parts for troubleshooting and repair.

By familiarizing yourself with the structure of the tool, you can more effectively address wear and tear issues, ensuring a smoother operation. Each piece, from the engine to the cutting mechanism, works together to achieve optimal performance, and recognizing their individual functions is essential for efficient care.

Accurate identification of each component is a crucial step in successful maintenance. Knowing which part needs attention allows for precise replacements and ensures that your equipment is always in top condition, ready for any task at hand.

Key Components of the Trimmer

Every trimming tool relies on a set of essential components that work together to provide efficient performance. Understanding these key elements will help you maintain your equipment, identify potential issues, and ensure its longevity. In this section, we’ll highlight the most important parts that contribute to the smooth operation of your tool.

The engine is the powerhouse, driving the mechanism that allows for cutting. Other critical components, such as the shaft, head, and line spool, ensure precise movement and effective trimming. Each element has a specific function that complements the others, creating a seamless experience when the tool is in use.

Regular inspection of these key components can prevent malfunctions and extend the life of your equipment. Knowing how to recognize wear and tear on each part will make it easier to identify when a replacement or repair is needed.

How to Use the Trimmer Component Breakdown

Understanding the structure of your tool is essential for effective maintenance and repairs. A detailed visual guide can help you easily identify each element, making it simpler to locate the specific parts that require attention. This section will explain how to make the most of such a guide for better troubleshooting and part replacement.

By studying the breakdown, you can quickly match the labels with the actual components on your equipment. This not only saves time but also ensures accuracy when ordering replacements or performing repairs. Knowing which components are connected and how they function together helps to prevent errors and enhances your repair skills.

To use this guide effectively, focus on the clear labeling of each component and cross-check with your tool to spot any issues. This method will streamline maintenance, allowing you to address problems swiftly and efficiently.