Proper maintenance is essential for the smooth operation of any lawn tractor. Identifying and understanding its components is the first step toward ensuring longevity and efficiency. Knowing the key elements that make up the machinery allows you to troubleshoot and replace parts when necessary.

In this guide, we will break down the structure and functionality of a typical tractor model, offering a clear overview of its various sections. This will help you familiarize yourself with its key features, so you can handle repairs and maintenance tasks with confidence.

Maintaining your machine becomes much easier when you have a clear visual reference of how each part fits together. Knowing where each component is located can save time and effort, whether you’re performing routine upkeep or addressing a specific issue.

Let’s dive deeper into understanding the layout of these vital components and how they work together to keep your machine running smoothly.

Understanding Lawn Tractor Components

Every lawn mower or tractor is made up of various parts that work together to ensure smooth operation. By understanding the essential components, you can identify any issues quickly and perform necessary repairs or replacements without delay. Each part plays a crucial role in the overall functionality, from the engine to the wheels.

Key Features of the Engine System

The engine is the heart of any machinery. It powers the entire system, enabling movement and operation. Understanding the engine’s components, such as the carburetor, fuel system, and ignition system, will help you diagnose common problems like poor starting or power loss. Regular maintenance, including oil changes and air filter checks, is essential for keeping the engine in top shape.

Drive and Steering Mechanisms

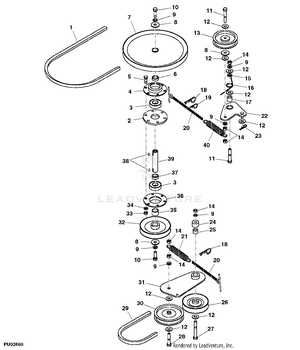

The drive system is responsible for transferring power from the engine to the wheels. This system includes belts, pulleys, and gears, all of which need to be in proper working order for the tractor to move efficiently. The steering mechanism ensures precise control, allowing for easy navigation and handling during mowing. Proper maintenance of these components ensures a smooth ride and prevents unnecessary wear and tear.

Understanding these critical parts helps you manage maintenance tasks effectively and avoid costly repairs in the future. Regularly checking for wear and tear, lubricating moving parts, and replacing worn-out components will extend the life of your machine.

How to Read the Components Layout

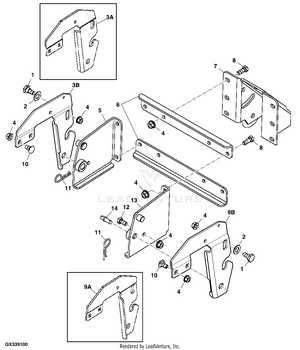

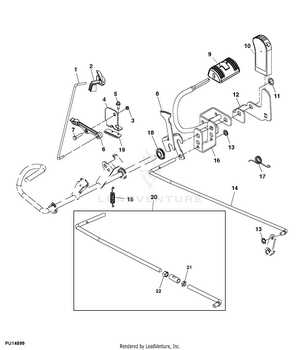

Understanding how to read a machinery layout is crucial for efficient maintenance and repair. A well-organized layout provides a clear visual representation of all the parts, showing how they connect and function together. This reference can guide you through identifying the correct components when troubleshooting or replacing parts.

Each section of the layout typically includes a numbered reference for each part, along with a description. By matching the numbers with the corresponding components in your machine, you can easily locate and replace worn-out or damaged parts. Make sure to follow the layout in the correct sequence to avoid confusion during reassembly.

Pay close attention to labels that indicate specific part numbers, as these can help you find the right replacement when needed. Additionally, the layout often includes helpful tips and symbols that provide extra information about how the parts fit together or their specific functions.

Common Issues and Replacement Parts

Every piece of machinery may encounter issues over time due to wear and tear, improper maintenance, or external factors. Recognizing common problems early and knowing which components need to be replaced can save time and prevent further damage. A thorough understanding of the potential issues can guide you through troubleshooting and repairs efficiently.

One of the most frequent problems is poor starting or engine misfires. This could be caused by a faulty ignition system or clogged filters. In such cases, replacing the spark plugs or cleaning the air filter can resolve the issue. Additionally, worn-out belts or damaged drive components can cause the machinery to move slowly or unevenly, requiring belt replacements or adjustments to the drive mechanism.

Maintaining an inventory of key replacement items like belts, filters, and spark plugs is advisable. These items often wear out and need to be replaced to ensure the machine continues to perform optimally. Regular inspections and replacing components at the first sign of damage will help maintain the efficiency and longevity of your equipment.

Addressing small issues quickly before they escalate into larger problems can save both time and money, allowing you to keep your machine in excellent working condition for longer periods.