When performing maintenance or repairs on your outdoor equipment, having a clear view of its internal structure is essential. A detailed illustration can help you identify each part and understand how they interact within the machine. This approach simplifies the process of assembling, disassembling, and troubleshooting any issues that may arise.

In this section, we’ll explore how to read and interpret the various elements that make up your equipment. With the right visual guide, even complex machines become easier to handle. From small fasteners to major components, every piece plays a crucial role in ensuring optimal performance.

By understanding these illustrations, you can more effectively manage repairs, replacements, and general upkeep. Whether you’re a seasoned professional or a first-time user, knowing how to navigate these diagrams will enhance your experience and extend the life of your machine.

Stihl FS70R Parts Breakdown

When dealing with any outdoor equipment, understanding the different components and their functions is crucial. A thorough examination of these elements helps ensure proper maintenance and smooth operation. By breaking down the machine into its individual pieces, users can easily identify which parts need attention, whether for repairs or replacements.

Key Components for Maintenance

Every machine is made up of several core elements that work together to ensure performance. The engine, fuel system, cutting mechanisms, and safety features each require regular checks. Understanding where these components fit within the assembly allows for faster troubleshooting and more efficient upkeep.

Assembly and Disassembly Insights

Knowing how to correctly assemble and disassemble your equipment is essential for effective repairs. The breakdown of each section and its relationship with others allows users to approach maintenance systematically. With the right approach, complex tasks like replacing worn-out components become more manageable.

How to Read the Parts Diagram

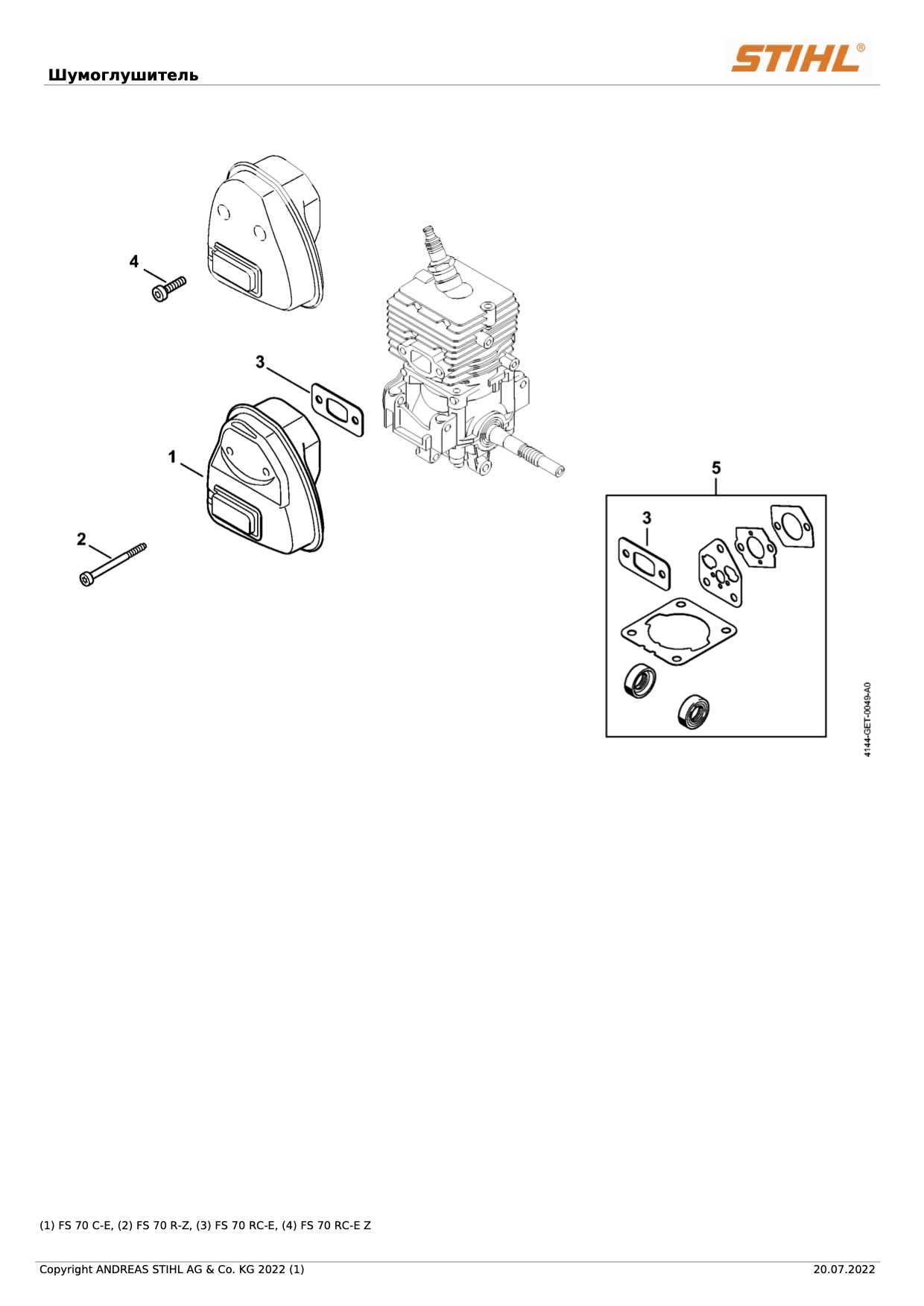

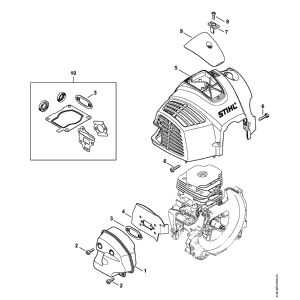

Understanding a visual representation of your equipment’s internal structure is essential for effective troubleshooting and repairs. These illustrations provide an overview of how components are arranged and connected, allowing you to identify individual parts and their functions. Properly interpreting these visuals can save time and improve accuracy during maintenance tasks.

Identifying Key Symbols and Labels

The first step in reading an illustration is recognizing the various symbols and labels used to represent the components. These may include numbers, letters, and specific markings that correspond to each piece within the system. Familiarizing yourself with the legend or key provided will help you understand which part is which and avoid confusion during assembly or disassembly.

Understanding the Flow and Connections

Once the parts are identified, it’s important to understand how they are connected and interact with one another. The flow of energy, fuel, or motion between components is often highlighted in these diagrams, giving you a clearer picture of how the system functions as a whole. This knowledge allows for more efficient repairs and ensures you are working with the equipment’s intended design.

Essential Components for Stihl FS70R Maintenance

Proper maintenance of your equipment relies on ensuring the key elements are in top condition. These critical components are responsible for the overall functionality and efficiency of the machine. Regular inspection and upkeep of these parts help prevent unexpected failures and ensure that the machine operates smoothly over time.

Among the most important elements are the engine components, which provide the necessary power for operation. This includes items like the spark plug, carburetor, and air filter. Keeping these parts clean and functioning optimally can significantly improve engine performance and longevity.

Another vital aspect is the fuel system, which includes the fuel lines, fuel filter, and tank. Regularly checking for leaks, blockages, or any signs of wear ensures that the engine receives a steady supply of fuel without interruptions. Neglecting this system can lead to poor engine performance or complete failure.

Finally, don’t forget about the cutting mechanism. Blades, trimmers, and related parts require frequent inspection and sharpening to maintain cutting efficiency. A dull blade or worn-out trimmer will not only decrease performance but also put unnecessary strain on the engine.