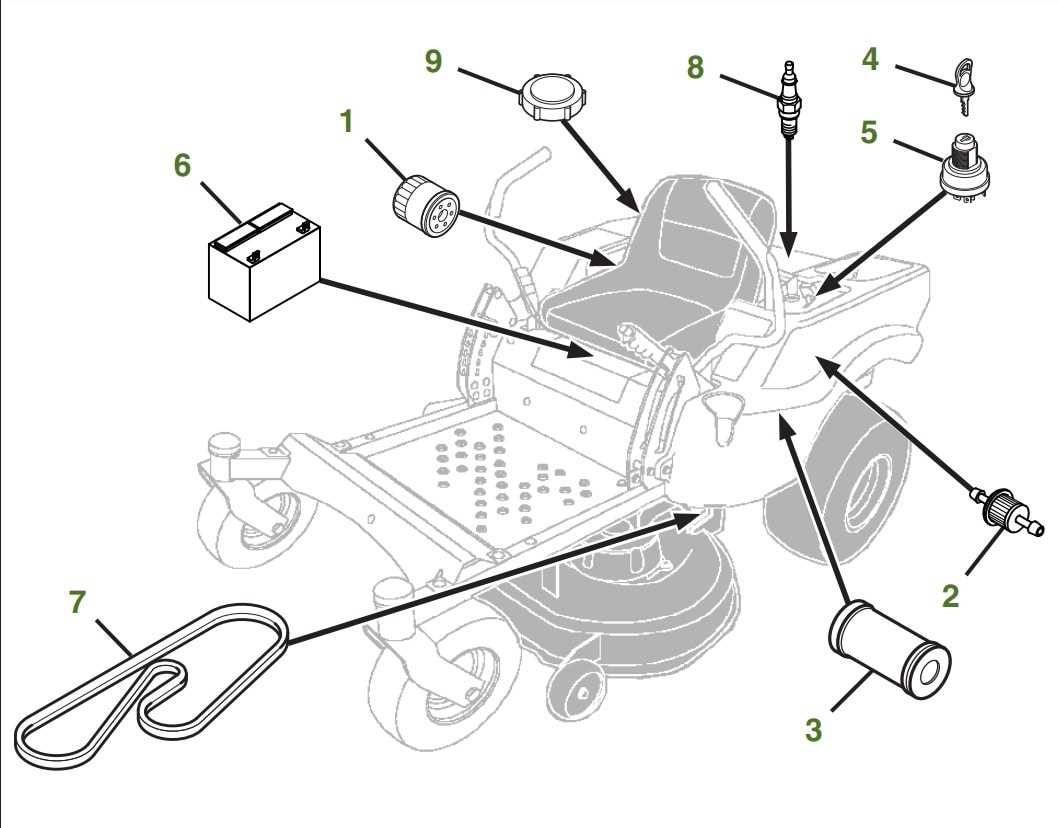

Proper maintenance of outdoor equipment requires understanding the intricate layout of each individual section. Knowing how every element connects and functions ensures efficient performance and longevity. For those working with grass cutting machinery, gaining insights into its configuration is crucial for both repair and upkeep.

In this guide, we will explore the essential elements that contribute to the effective operation of such machines. Whether you are performing routine checks or diagnosing issues, a clear understanding of these components is necessary. We’ll cover common components, their interconnections, and how they work together to deliver consistent results.

Maintenance tips and troubleshooting will also be provided to help you resolve typical issues, enhancing the lifespan of the equipment. Being able to visualize the parts and their respective roles can greatly simplify the process, allowing for quicker repairs and a smoother operation.

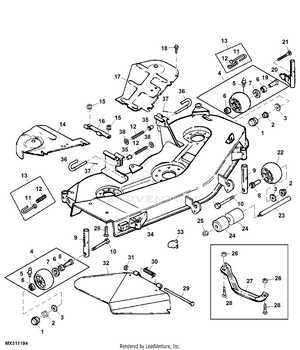

Understanding the Mower Deck Components

Effective operation of a grass cutting machine depends on the seamless interaction between various mechanical elements. Each section plays a vital role in ensuring the machine functions properly, contributing to both efficiency and durability. Familiarity with the essential components allows for more informed maintenance and troubleshooting.

The rotating blades, support structures, and drive mechanisms all work in tandem to achieve optimal cutting results. Understanding their respective functions and how they integrate with other systems can help users detect potential issues before they become problematic. A well-maintained setup reduces the risk of damage and ensures consistent performance during operation.

Recognizing each component’s position and purpose will also assist in the assembly and disassembly processes. This knowledge not only aids in repair tasks but also in performing necessary adjustments to ensure the machine operates smoothly and safely over time.

Step-by-Step Assembly of Mower Deck

Assembling outdoor equipment requires precision and a clear understanding of each element’s role in the overall structure. This section outlines the process of putting together the key components in a logical sequence, ensuring each piece is correctly aligned and securely attached for optimal function.

Begin by positioning the main frame and securing it in place. Once the base is stable, attach the rotating blades and connect them to the drive system. It is essential to ensure the blades are properly aligned to avoid uneven cutting and unnecessary wear. Check for any signs of wear on the blade mounts before assembly to ensure durability.

After completing the blade attachment, move on to install the support brackets and tensioning mechanisms. These elements are crucial for maintaining the proper height and balance during operation. Once the system is fully assembled, double-check all fastenings and test the movement to ensure smooth functionality before use.

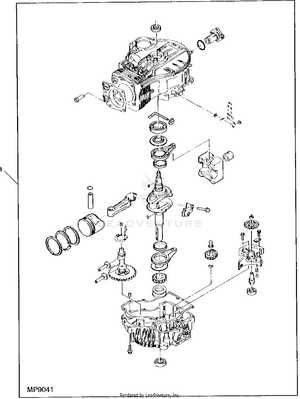

Common Issues with Mower Deck Parts

Understanding the most frequent problems that arise with cutting equipment is essential for efficient maintenance and repair. Many of these issues are related to wear and tear, improper alignment, or faulty connections that can impact performance and cause unexpected breakdowns.

One common issue is the improper functioning of rotating blades, which may become misaligned or dull over time, leading to inefficient cutting. Another frequent problem is the failure of tensioning mechanisms, which can cause instability during operation or improper cutting height. Additionally, issues with the drive system can result in inconsistent blade movement or complete failure.

Regular inspections and timely repairs can prevent these issues from affecting the overall performance. Ensuring that all components are well-maintained and properly adjusted is the key to prolonging the life of the equipment and maintaining smooth operation.