When it comes to maintaining or repairing a power tool, having a clear understanding of its internal structure is essential. Knowing the different components and their functions helps ensure smooth operation and longevity of the device. A well-organized illustration of these elements can make the process much easier, allowing users to quickly locate the required parts and troubleshoot effectively.

Identifying the right elements is crucial for anyone who wishes to replace or repair a tool. With a detailed breakdown of the tool’s design, users can pinpoint the specific areas that need attention. This guide provides a helpful overview of the most important components, simplifying the repair and maintenance process.

Whether you’re looking to replace a worn-out component or conducting routine checks, this guide will assist you in getting the most out of your tool, ensuring it functions at its best for years to come.

Understanding the Tool Components

Every power tool consists of various elements that work together to ensure its functionality. Having a clear understanding of how these components fit together is essential for effective maintenance and repair. By recognizing the role each part plays in the operation of the device, users can identify issues quickly and address them efficiently.

Key Functional Elements

The main components of any tool typically include the motor, trigger mechanism, and feed system. Each plays a unique role in the tool’s operation, and understanding their functions can help in diagnosing malfunctions. For instance, the motor drives the tool’s performance, while the trigger mechanism controls its activation. A malfunction in any of these parts can disrupt the tool’s functionality, making repairs more complicated.

Exploring the Supportive Components

In addition to the core operational parts, there are several smaller elements that support the tool’s overall efficiency. These include fasteners, springs, and safety mechanisms. These components may seem minor, but they are crucial for keeping the tool in optimal condition. Regularly checking these elements ensures smoother performance and longer lifespan of the tool.

How to Identify Components in the Breakdown

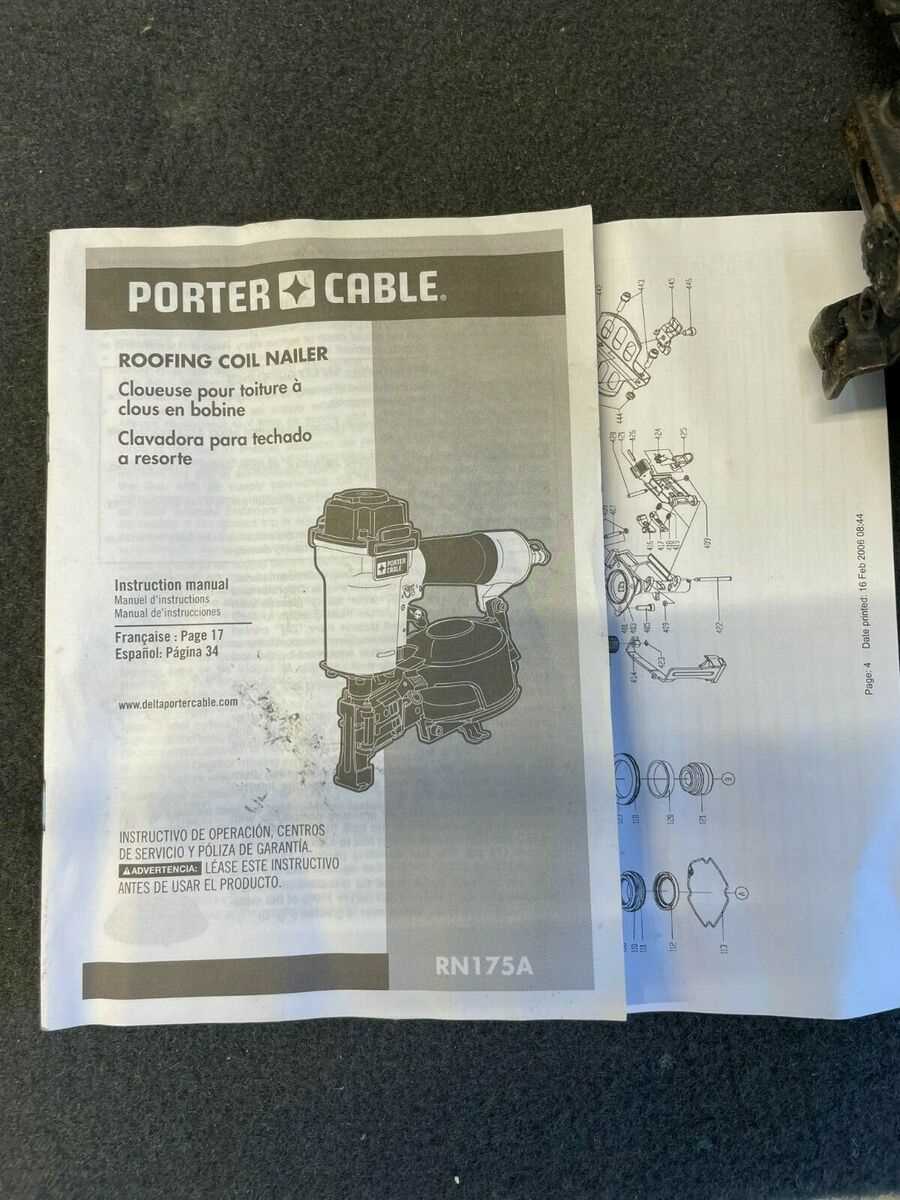

Understanding how to recognize different elements within an illustration is key to effective repairs and maintenance. These detailed visuals often feature labeled sections that help users pinpoint the exact location of each component. Knowing how to read these visuals ensures that users can quickly identify the parts that need attention without confusion.

Steps for Identification

When working with an illustration, follow these simple steps to identify the necessary components:

- Start by locating the main functional units, such as the motor and trigger mechanism.

- Examine the connections between different parts to understand how they work together.

- Look for labels or markings that indicate specific components, which help in easy identification.

- Use reference numbers or symbols in the diagram to cross-check against a parts list if available.

Tips for Clear Identification

To make the identification process easier, keep these tips in mind:

- Zoom in on the visual to get a clearer look at each section, ensuring no part is overlooked.

- Familiarize yourself with common shapes and features of key components for quicker recognition.

- Always refer to the tool’s manual for guidance on interpreting the diagram accurately.

Tips for Replacing Tool Components

When it comes to replacing damaged or worn-out components in a tool, following the correct procedure can prevent further issues and ensure proper functionality. Taking the time to carefully remove and install each part is crucial for maintaining the tool’s efficiency and longevity. Here are some helpful tips to guide you through the replacement process.

Before starting, ensure you have the right replacement parts. Double-check the specifications to match the components with your tool’s model. Using the correct parts is essential for maintaining the tool’s performance and preventing potential damage.

Next, gather all the necessary tools for the job. You’ll likely need screwdrivers, wrenches, or pliers to remove and secure components. Having the proper tools on hand will make the replacement process smoother and more efficient.

As you proceed with the replacement, take note of how the original parts are positioned. Keep track of any screws or fasteners removed during the process, and make sure they are reinstalled correctly. This will help prevent any parts from being left loose or improperly attached.

Lastly, after replacing the components, test the tool to ensure everything is working as expected. Run a few checks to verify that the new parts are functioning correctly and that the tool is operating smoothly. Regularly performing this maintenance will help extend the tool’s lifespan and keep it in top condition.