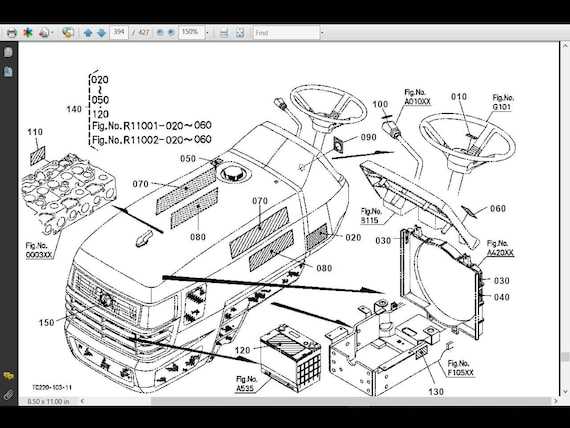

When working with heavy machinery, having a clear visual guide to its internal components is essential for effective maintenance and repairs. Whether you are a professional technician or a hobbyist, being able to identify and understand the key elements of a machine’s structure can save valuable time and effort.

Detailed illustrations provide a comprehensive view of the individual parts, showing their arrangement and connections within the system. This helps in diagnosing issues, planning repairs, and ensuring that everything functions as intended. Proper identification of each component is the first step toward efficient troubleshooting and maintenance.

Having access to this type of information not only makes repairs easier but also ensures that your equipment remains in optimal working condition. Understanding these connections and the role of each piece is crucial for long-term performance and reliability of the machinery. A well-maintained machine not only performs better but also lasts longer, providing greater value in the long run.

Understanding the Tractor Component Layout

Having a clear view of a machine’s internal structure is crucial for efficient maintenance and repair. This type of layout helps users comprehend how different parts interact and work together. It allows for easier identification of components and a better understanding of the machine’s functionality as a whole.

Each piece within the system plays a specific role, from driving mechanisms to essential operational functions. Recognizing the relationship between these elements is key to ensuring proper performance and quick identification of potential issues. A detailed breakdown not only facilitates troubleshooting but also assists in planning preventive maintenance tasks.

With a solid grasp of the arrangement and connections, operators can address problems more effectively and perform repairs with confidence. Maintaining this knowledge ensures longevity and optimal performance, making it an invaluable resource for anyone working with complex machinery.

How to Read the Tractor Layout

Understanding a machine’s internal blueprint is essential for effective maintenance and repairs. A visual guide provides clear representations of the components, their connections, and functions, enabling users to quickly navigate through the system. Knowing how to interpret these visuals ensures that each element can be easily located and understood in the context of the overall machine.

The key to reading this type of guide lies in recognizing the symbols and notations used to represent each component. Components are usually grouped by their function, making it easier to follow their relationships and placement within the system. It’s important to familiarize yourself with these symbols before attempting to troubleshoot or replace parts.

Once you are comfortable with the layout and terminology, you’ll be able to identify problem areas, plan repairs, and maintain the machine more efficiently. This skill improves the troubleshooting process and minimizes downtime by streamlining the identification of necessary parts and procedures.

Common Issues and Solutions for Tractor Components

Like any complex machinery, tractors can experience a range of issues due to wear and tear, environmental factors, or improper usage. Understanding the common problems that may arise with the internal components is essential for timely intervention and effective repairs. Addressing these issues promptly can prevent more serious damage and ensure the continued functionality of the machine.

One frequent problem is the malfunction of hydraulic systems, which may be caused by fluid leakage or clogged filters. Regular inspection and maintenance of seals and filters are key to preventing such issues. Another common issue is the failure of electrical connections, which can disrupt the operation of key systems. Ensuring that all wiring is intact and connections are secure can prevent these disruptions.

Additionally, engine performance problems often arise due to air and fuel system blockages. Routine cleaning of air filters and fuel injectors can resolve such issues. Addressing these common challenges will not only improve the machine’s efficiency but also extend its lifespan, reducing the need for costly repairs down the road.