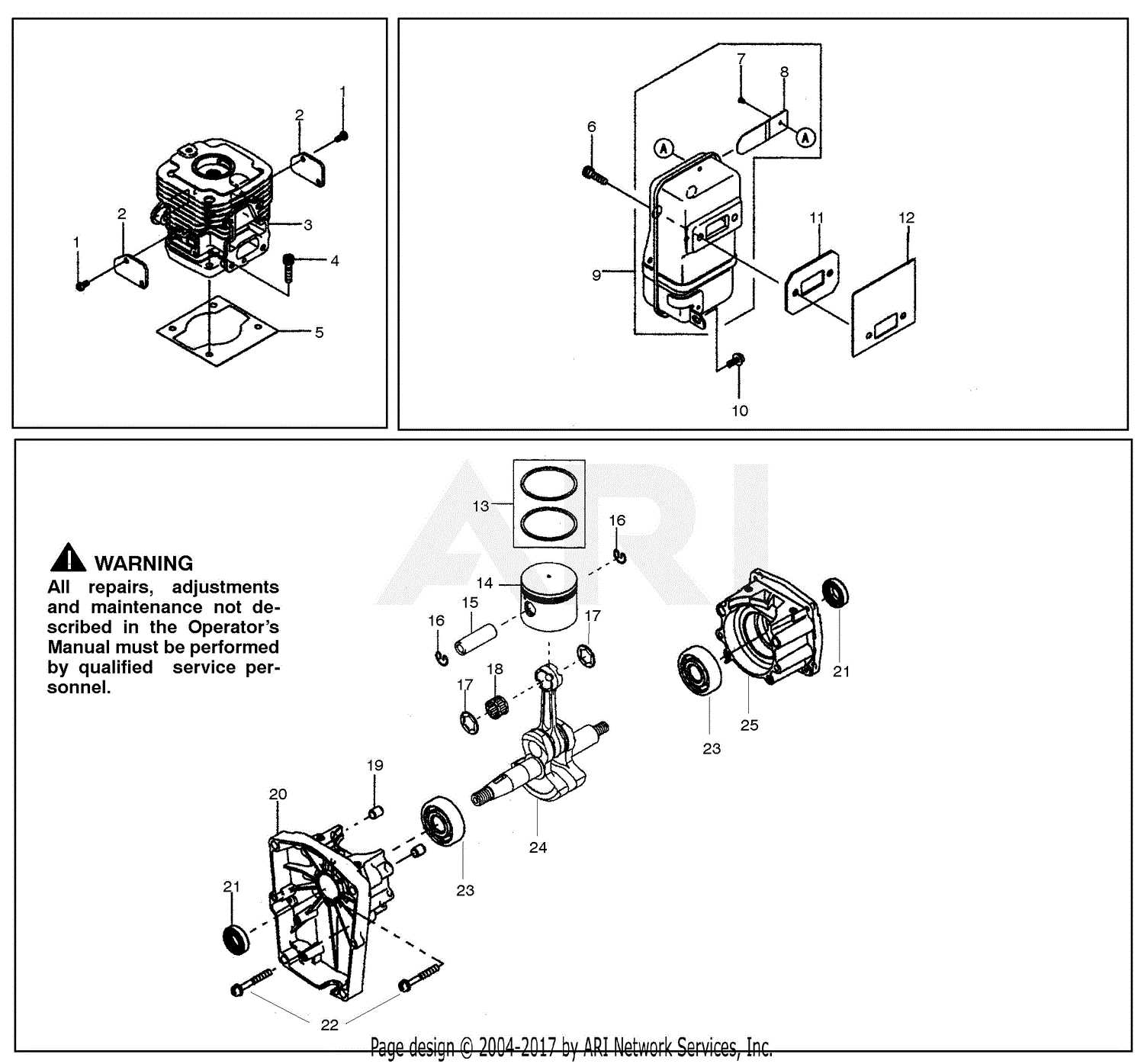

Proper maintenance and repair of any outdoor machinery depend on a clear understanding of its individual components. Identifying the correct placement and function of each element is essential for ensuring the equipment operates efficiently. Familiarizing yourself with the layout of critical pieces and their interactions is key to avoiding costly mistakes and improving the longevity of the tool.

Maintenance and troubleshooting become much more straightforward when one knows how the system is structured. By taking the time to analyze each section and its corresponding parts, users can pinpoint the exact cause of any issue and take the appropriate steps to resolve it.

Whether you’re looking to perform basic repairs or more advanced upgrades, understanding the configuration of the various parts is crucial. This knowledge empowers users to carry out adjustments and replacements with confidence, ensuring smooth operation for extended periods.

Poulan Pro PR48BT Parts Overview

Understanding the different elements of outdoor machinery is essential for efficient operation and maintenance. Each component plays a specific role, contributing to the overall functionality of the device. Whether you are assembling a new model or troubleshooting an existing one, being familiar with the essential parts will help ensure everything runs smoothly.

Key Elements to Identify

The core components of any device should be understood in terms of their purpose and function. Some of the most important include:

- Engine housing – protects the internal mechanism

- Drive shaft – connects the engine to the working parts

- Handle assembly – provides control and support for the user

- Throttle control – regulates power and speed settings

- Fuel system – supplies the necessary energy for operation

Maintenance and Replacement Tips

Regular upkeep involves inspecting and replacing certain components to maintain optimal performance. Common maintenance tasks include:

- Checking for wear and tear on the drive shaft and handle assembly

- Cleaning or replacing filters in the fuel system

- Inspecting and adjusting the throttle mechanism for proper response

Replacing worn parts ensures the machine operates at peak performance, reducing the risk of mechanical failure and improving safety during use.

Understanding Component Placement and Function

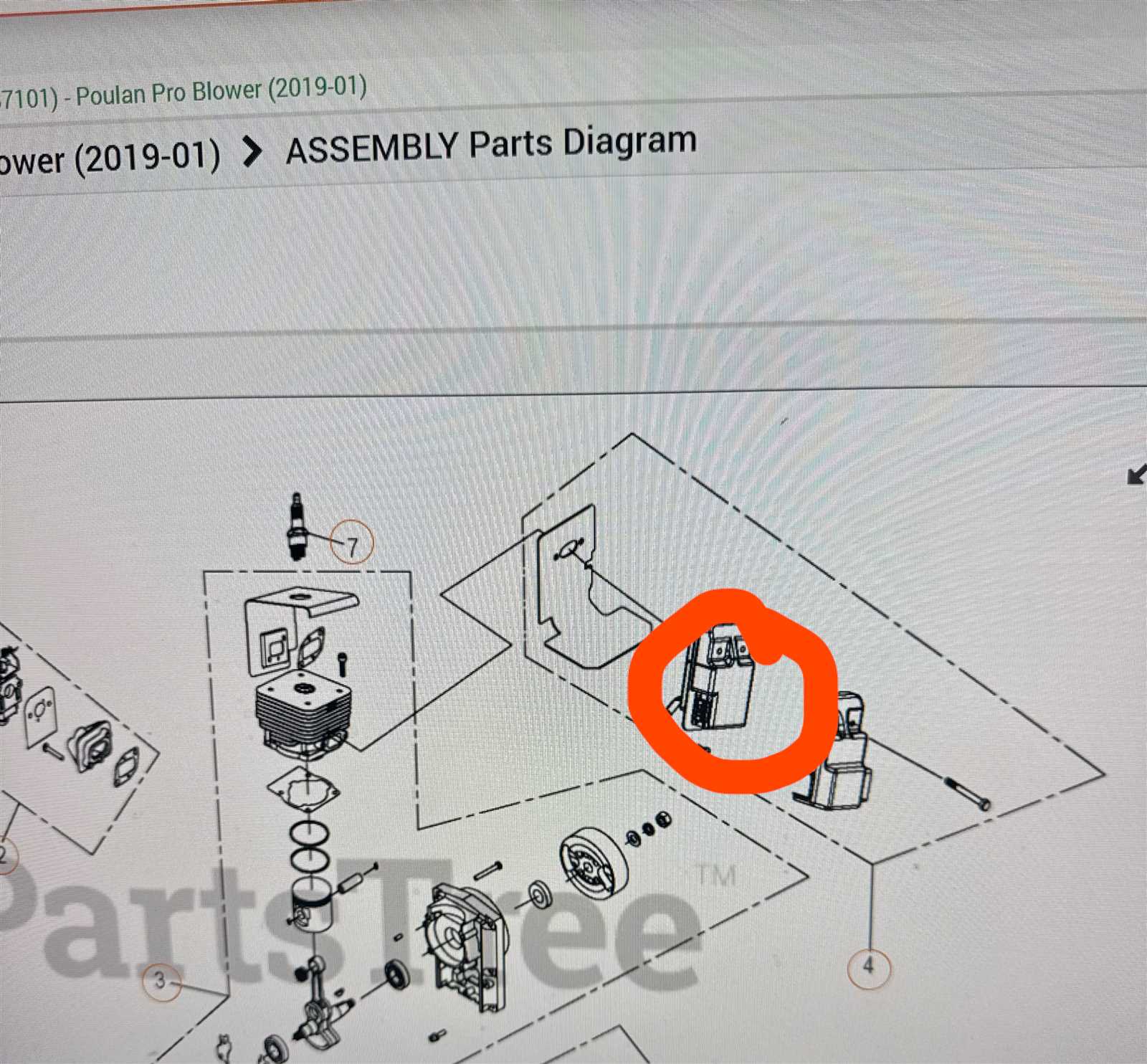

The arrangement of various components within machinery plays a crucial role in its overall performance. Proper placement ensures that each part functions optimally, contributing to the smooth operation and longevity of the equipment. By understanding how each element works together, users can troubleshoot more effectively and perform necessary repairs with precision.

Critical Components and Their Functions

Each part of the machine is designed with a specific purpose in mind. Below are key components and their functions:

- Engine casing: Houses and protects the internal engine components from debris and external damage.

- Transmission system: Transfers power from the engine to the working parts, ensuring consistent operation.

- Control handles: Allow the user to steer and control the movement of the device for precise operation.

- Throttle mechanism: Regulates the engine’s speed, enabling control over power output during use.

Effective Troubleshooting through Placement Awareness

Recognizing the layout of the machine’s components is key to diagnosing issues. Proper knowledge of how each element is positioned can help users identify and address problems with ease. For instance, if the throttle isn’t responding, understanding its position relative to other parts may highlight issues with the linkage or other connected systems.

Key Components of Poulan Pro PR48BT

To ensure smooth operation and effective performance, understanding the fundamental parts of a machine is essential. The main components work together to create a system that allows the equipment to perform its intended tasks efficiently. Each piece plays a significant role in maintaining stability, power transfer, and overall functionality.

Essential Components to Recognize

Here are some of the key elements that contribute to the performance of the device:

- Engine housing: This protects the internal mechanisms from external damage and debris.

- Drive shaft: Transfers mechanical power from the engine to the working components, ensuring movement and function.

- Throttle control: Allows users to regulate the engine speed, offering flexibility and control during use.

- Handle assembly: Provides a secure grip for the user, enabling full control over the machinery.

Understanding Their Roles

Each of these parts has a vital function in the overall operation of the equipment. The engine housing protects sensitive internal components, while the drive shaft ensures that energy is transferred from the engine to the other moving parts. The throttle control adjusts the power output, allowing for fine-tuned performance, and the handle assembly is essential for comfortable and safe operation by the user.

Exploring Essential Parts and Features

Understanding the key elements of machinery is critical for anyone looking to maintain or repair their equipment effectively. These components are designed to work together, ensuring smooth performance and enabling users to handle tasks efficiently. Each feature contributes to the machine’s overall functionality, making it important to recognize their roles and understand how they interact with one another.

Key Features to Know

Several critical features are integral to the operation of the equipment:

- Power system: Provides the energy required for operation, ensuring the machine can perform its tasks effectively.

- Control mechanism: Allows the user to adjust settings such as speed and power, offering flexibility during use.

- Support frame: The structure that holds all components in place, providing stability during operation.

- Cooling system: Prevents overheating by dissipating excess heat generated by the engine during use.

Understanding Their Impact

Each feature plays an important role in ensuring that the equipment functions at its best. The power system provides the necessary energy, while the control mechanism offers users the ability to adjust the performance as needed. The support frame ensures that all parts stay secure during operation, and the cooling system prevents damage by managing temperature. Together, these features enable the machinery to perform effectively and reliably for extended periods of time.

Maintenance Tips for Poulan Pro Parts

Proper maintenance is crucial for ensuring that machinery continues to operate efficiently and lasts for many years. Regular checks and routine care can prevent wear and tear, avoid costly repairs, and enhance performance. Understanding the necessary upkeep for each component is vital for maintaining the overall functionality of the device.

Routine Checks and Care

Regular inspection of key components can help identify potential issues before they become major problems. Here are some essential maintenance tasks to keep in mind:

- Clean and replace filters: Ensuring that air and fuel filters are free from debris will improve airflow and prevent engine damage.

- Inspect moving parts: Check components like the drive mechanism for signs of wear or damage, and lubricate parts as needed to prevent friction.

- Examine the cooling system: Make sure the cooling system is functioning properly by cleaning it regularly and ensuring there are no blockages in airflow.

Storing Your Equipment

Proper storage is just as important as routine maintenance. Always store your equipment in a dry, cool area to protect it from the elements. If storing for extended periods, drain fuel and clean all surfaces to avoid buildup that could affect performance when you resume use.