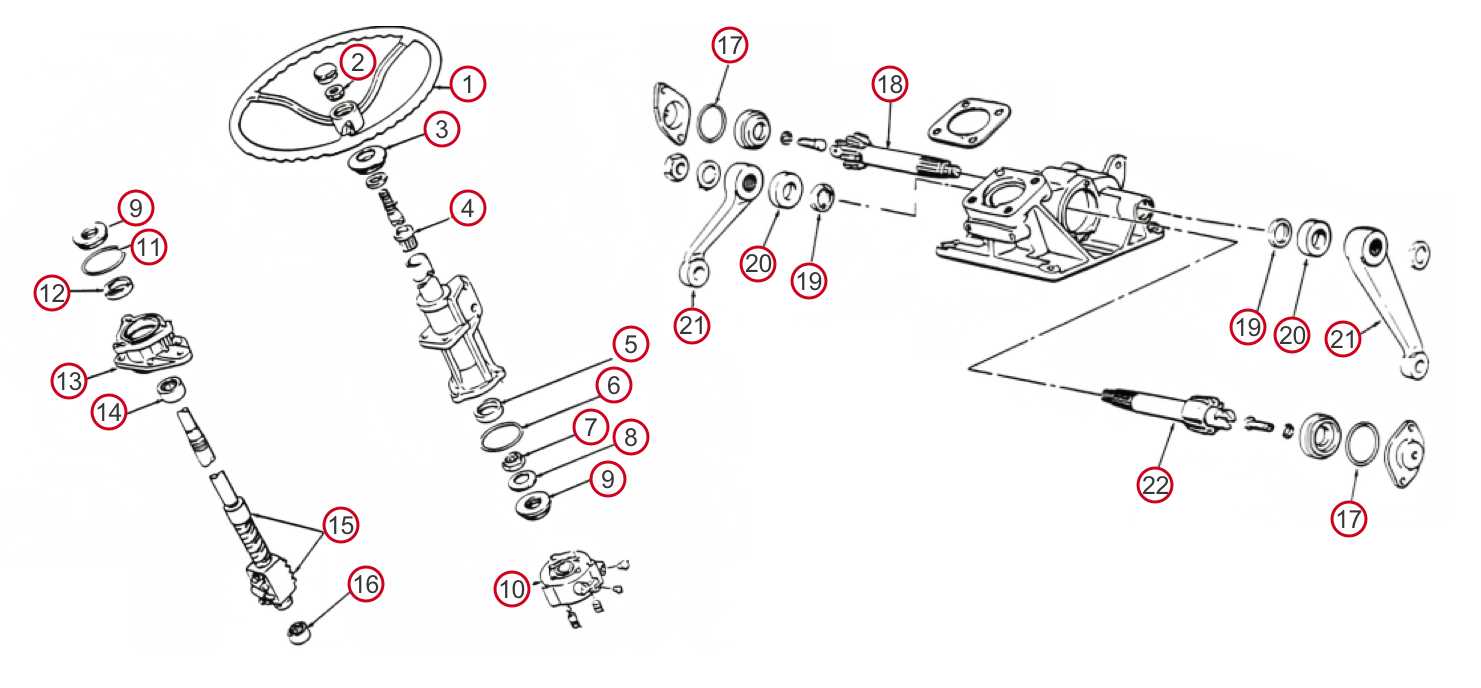

Understanding the layout and organization of machine elements is crucial for anyone maintaining or repairing agricultural equipment. A clear representation of each segment helps identify potential issues and ensures smooth operation. This knowledge is essential for proper maintenance, reducing downtime and extending the life of your machinery.

Accurate visual representations play a key role in simplifying complex repair processes. By clearly marking each component, it becomes easier to recognize the necessary parts for specific repairs. Whether you’re a professional or a DIY enthusiast, having an organized reference at hand can save time and effort.

In this guide, we will focus on breaking down the essential elements of machinery and how to approach their identification. With the right information, you can make informed decisions when it comes to maintenance and replacements, ensuring optimal performance throughout the year.

Understanding the Tractor Components

Every piece of machinery is made up of numerous components that work together to ensure optimal functionality. Knowing how these elements interact with each other can greatly improve the maintenance and troubleshooting process. By recognizing the function of each part, you can effectively address issues before they become major problems.

Each section of the machine has a specific role, whether it’s related to the engine, transmission, or control mechanisms. Understanding these functions will help you pinpoint the cause of any malfunction more efficiently. Moreover, knowing where each component is located simplifies repair tasks and reduces downtime during maintenance.

In this section, we’ll explore the different categories of components that make up the system, discussing their roles and how they contribute to the overall performance of the equipment. This knowledge not only aids in fixing problems but also ensures better care for the machinery over time.

Key Components in the Machine Layout

Every complex machine is made up of several vital elements that function together to create a seamless operation. Identifying and understanding these essential components is crucial for both proper maintenance and efficient repair. Knowing which parts are critical allows for targeted troubleshooting and helps extend the lifespan of the equipment.

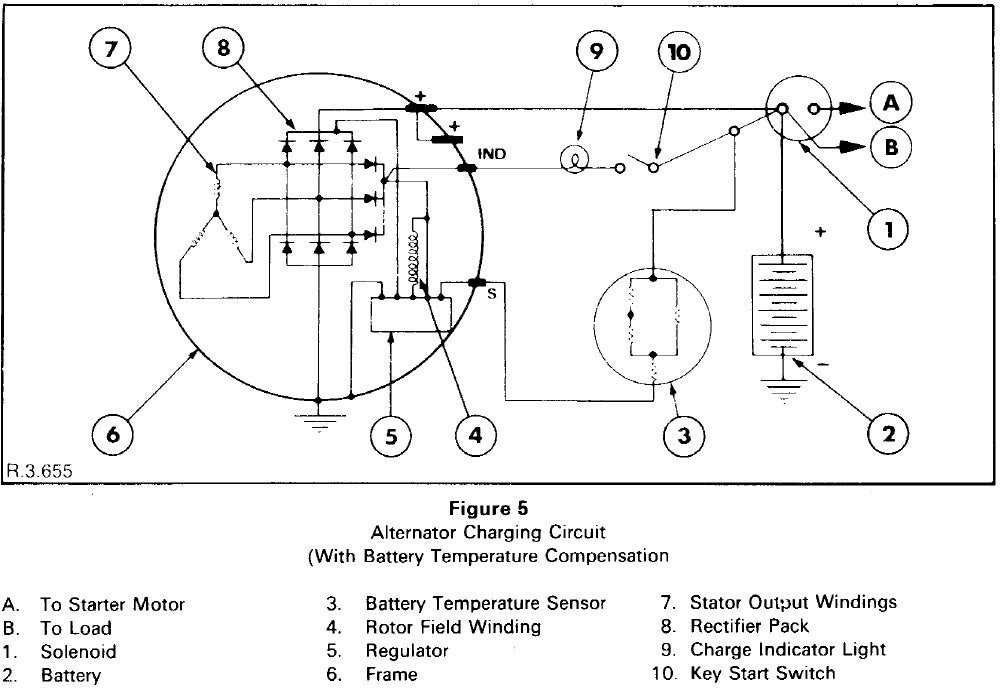

Engine and Power System

The engine is the heart of any machine, driving the power needed for all functions. It’s essential to understand the key components of the engine, including the fuel system, cooling system, and exhaust components. These work in unison to ensure smooth and consistent performance. Regular checks and maintenance of the engine ensure it operates efficiently over time.

Transmission and Control Mechanisms

The transmission system is responsible for transferring power from the engine to the wheels or other working parts of the machine. This includes gears, shafts, and various linkages that allow for controlled movement. Understanding the transmission system is vital for diagnosing issues related to speed, movement, and power distribution. Ensuring proper alignment and fluid levels in these systems can prevent costly repairs.

How to Identify Components for Replacement

When equipment begins to show signs of wear or malfunctions, recognizing the right components that need replacement becomes essential. Accurately identifying these parts ensures that the correct replacements are sourced, reducing unnecessary downtime and repair costs. A systematic approach is key to determining which parts need attention and when.

Visual Inspection and Signs of Wear

Start by carefully inspecting the machinery for visible signs of damage or wear. Cracks, corrosion, excessive dirt, and fluid leaks are common indicators that a component may need replacement. Pay attention to parts that show wear due to friction or heat, such as belts, seals, or bearings. Identifying these issues early can prevent more serious damage in the future.

Consulting the Manufacturer’s Guide

Using the manufacturer’s manual or a detailed component layout can help identify specific parts that are at risk of failure. These resources provide essential information about the lifespan and maintenance needs of each part. Comparing your findings with the guide will help confirm which components need to be replaced and ensure compatibility with new parts.