When it comes to maintaining and repairing machinery, having a clear understanding of its assembly is essential. Knowing how each element fits into the overall structure allows for easier identification of issues and smoother repairs.

In this section, we will explore how to identify the various components of your equipment, as well as provide guidance on replacing worn-out parts. A detailed overview of the structure will give you the confidence to handle maintenance tasks effectively.

By following this guide, you will gain valuable insights into the various elements that make up your device and learn how to ensure its optimal performance over time. Whether you are performing routine maintenance or addressing a specific problem, understanding the setup is the first step toward success.

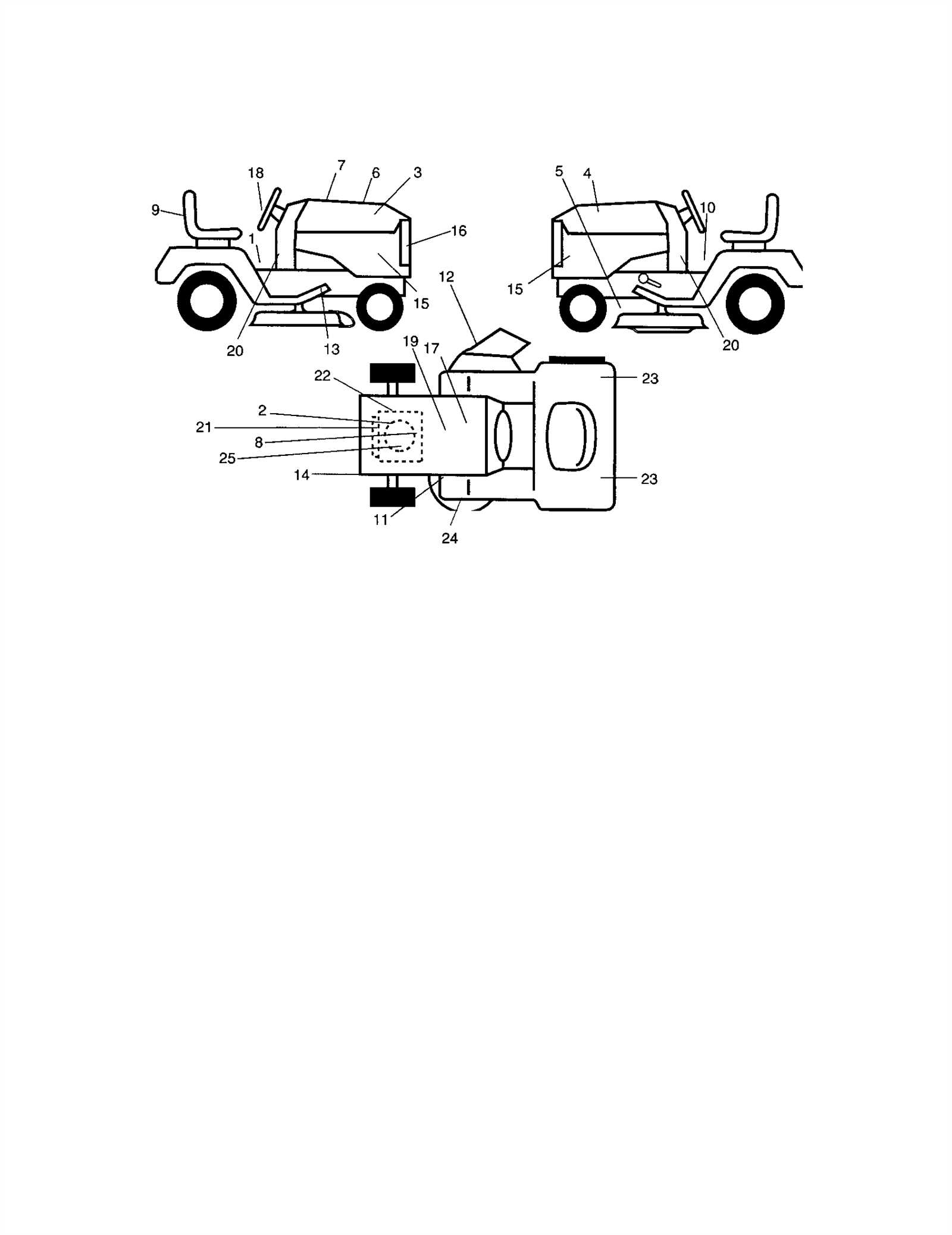

Understanding Equipment Assembly and Components

To effectively manage the maintenance and repair of your machinery, a thorough understanding of its structure is crucial. The assembly of any device consists of various elements that work together to ensure proper functioning. By knowing the exact arrangement and role of each component, you can identify issues more efficiently and take the appropriate steps for resolution.

Identifying Key Components

Each machine is made up of different sections that serve specific functions. These sections can include moving parts, electrical components, and mechanical structures. Familiarizing yourself with the overall setup allows you to pinpoint the source of any problem, whether it’s related to power, performance, or functionality. Understanding how each part interacts with others is essential for troubleshooting and making informed decisions when repairs are needed.

Practical Guide for Repairs

Once you are familiar with the internal configuration, you can proceed with repairs or replacements as needed. This knowledge not only aids in replacing damaged parts but also helps in ensuring the machine’s longevity. By following the appropriate maintenance steps, you can keep your equipment operating at its best, avoiding frequent breakdowns and ensuring reliable performance over time.

Identifying Key Components of Your Equipment

Understanding the core elements of your machinery is essential for effective maintenance and troubleshooting. Every device is designed with specific components that work in unison to ensure its smooth operation. Identifying these crucial parts allows for better management of repairs and overall upkeep.

The machine consists of various systems, including power sources, control mechanisms, and moving elements. Each component plays a vital role, and recognizing these parts enables quick diagnosis and efficient problem-solving. Familiarity with the structure helps you address issues before they become major setbacks.

Once you have an understanding of the key components, you can more easily locate faults and take appropriate actions, whether that involves simple repairs or more complex replacements. Proper knowledge of each element will help maintain the overall performance of your equipment for a longer time.

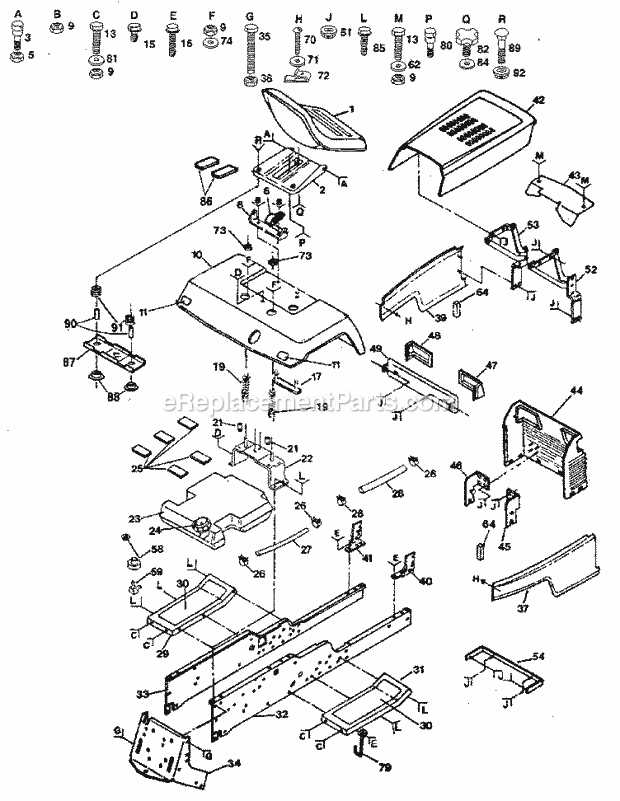

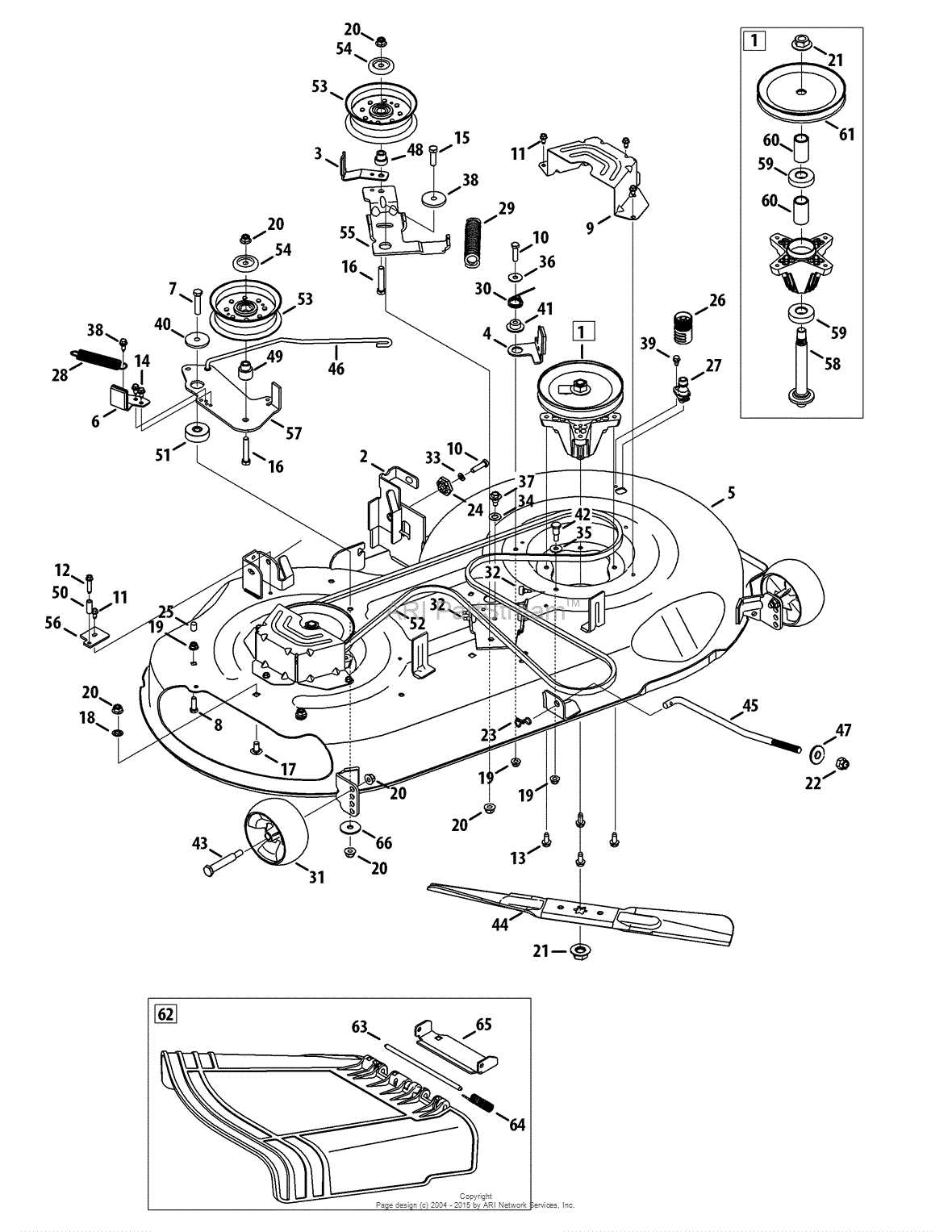

How to Replace Components in Your Equipment

Replacing worn or damaged components is a key aspect of keeping your equipment in optimal working condition. Understanding the replacement process is essential for ensuring the longevity and performance of the device. Whether you are dealing with mechanical or electrical parts, following a systematic approach will help you complete the task effectively and safely.

Preparing for the Replacement

Before starting the replacement process, make sure you have all the necessary tools and the correct replacement components. Disconnect the power source and take precautions to avoid damage during the disassembly. Having a clear understanding of the device’s configuration will make it easier to locate the damaged parts and access them without causing unnecessary stress to the system.

Replacing and Reassembling the Equipment

Once you’ve removed the faulty components, carefully install the new ones in their designated positions. Double-check that each part is securely attached and properly connected to the system. After the replacement is complete, reassemble the device and test it to ensure everything is functioning as it should. Regular checks and maintenance will help avoid future issues and keep your equipment performing at its best.