When maintaining or repairing your boat’s motor, understanding its internal structure is essential. Whether you’re troubleshooting or replacing broken elements, knowing how everything fits together will help ensure the longevity and efficiency of your equipment.

In this section, we’ll provide a detailed overview of the essential elements of an electric trolling motor. A clear understanding of each component’s role can simplify the repair process and guide you in selecting the right replacement parts.

With a well-organized schematic, identifying each piece becomes much easier. This can save time and effort, making maintenance tasks smoother and more effective, especially when dealing with specific issues that require precise part identification.

Understanding Minn Kota Edge 70 Components

To effectively maintain and repair your boat’s motor, it is crucial to familiarize yourself with its main components. Every element of the motor plays a unique role in ensuring smooth operation, and identifying these components can significantly improve your troubleshooting and repair process.

Each motor typically consists of several core sections that work together to power and control the device. Recognizing how these sections interact will help you identify potential issues faster and determine which components require attention.

Motor Housing and Shaft

The motor housing serves as the protective shell for internal components, preventing water and debris from causing damage. The shaft, connected to the housing, transmits power from the motor to the propeller, enabling it to move the boat efficiently. Understanding how these parts work together ensures that you can spot wear and tear that could lead to operational problems.

Propeller and Drive Mechanism

The propeller and the drive mechanism work in tandem to generate propulsion. The drive mechanism connects directly to the motor, transferring its power to the propeller blades, which then push the water to move the boat. Keeping these parts in optimal condition is essential for maintaining smooth movement and performance, especially in different water conditions.

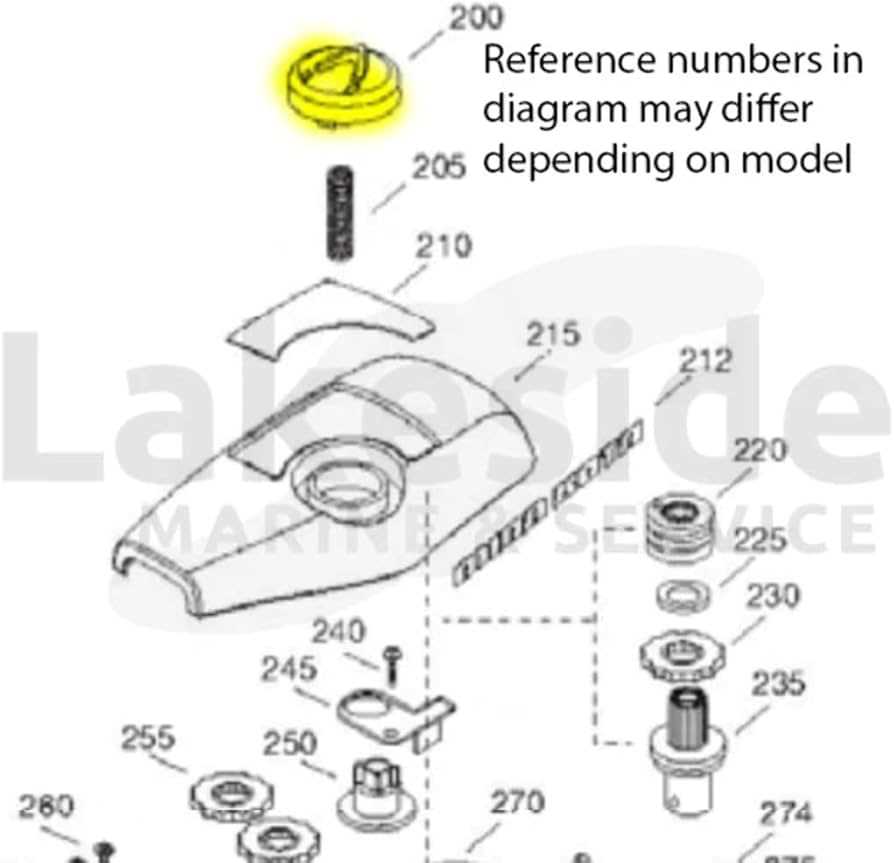

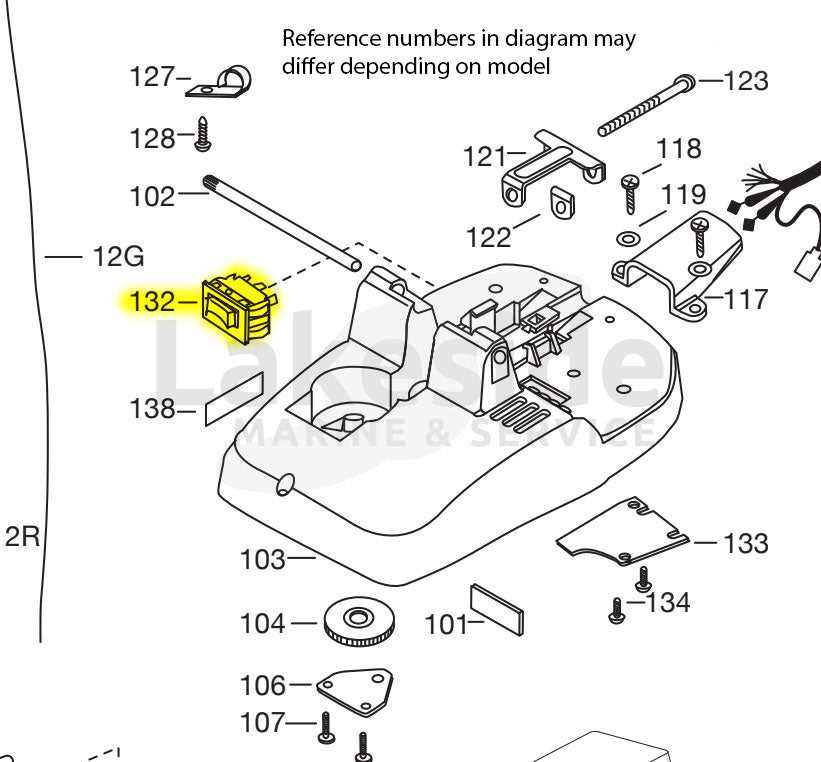

How to Read the Parts Diagram

Understanding a schematic of your motor’s components can be incredibly helpful when performing maintenance or repairs. A well-organized chart or drawing allows you to identify each element within the system, making it easier to locate specific pieces when needed.

When reading the schematic, start by locating the key sections that correspond to the areas you need to examine. The diagram typically shows all the important components, grouped logically based on their function or location in the motor. Pay attention to the labels and numbers, as these will guide you to the exact parts and make it easier to find replacements.

By following the visual cues and matching the labeled components with the physical parts on your motor, you can quickly identify what needs attention. This process streamlines repairs and ensures that no crucial part is overlooked, helping to extend the life of the motor.

Common Issues and Part Replacement Tips

Like any mechanical system, your motor may face some common issues over time. Recognizing these problems early and knowing how to address them can save time, effort, and money. By identifying the cause of malfunctioning or worn-out components, you can keep the system running smoothly and avoid unnecessary repairs.

Many of the most frequent issues arise from wear and tear, improper maintenance, or environmental factors. Identifying the right components that need replacement can be tricky without the right resources. This section will guide you through some common problems and provide useful tips for replacing the damaged elements.

Motor Stops Working or Runs Intermittently

If the motor suddenly stops working or operates intermittently, the issue could lie with the wiring or the internal connections. Check for loose or corroded connections and ensure the power supply is stable. If the issue persists, it might be time to replace the motor’s internal components such as the brushes or stator, which can wear out over time.

Reduced Propulsion or Slow Movement

A common issue with electric motors is reduced propulsion, which may result from a worn-out propeller or a malfunctioning drive system. Inspect the propeller for any signs of damage or debris that may cause obstruction. If the propeller is fine, the drive system or motor shaft might require servicing or replacement to restore proper function.