For anyone looking to maintain or repair their equipment, it is essential to have a clear understanding of how each component fits into the overall system. The proper functioning of each part is crucial to ensure optimal performance and longevity. Knowing how to identify and replace individual elements can make a significant difference in the ease and success of repairs.

In this guide, we will explore the key components of the system, explaining their role and importance. Understanding the layout and functionality of each part will not only aid in troubleshooting but also help in making informed decisions when it comes to maintenance and replacement. Whether you are a seasoned professional or a first-time user, having a reference to the various parts can simplify the process.

Having access to detailed visual resources and clear descriptions of the components can make all the difference. With this information, you can navigate repairs with confidence, ensuring that your equipment remains in top condition.

Understanding Nautilus CC Plus Components

When working with complex equipment, it is essential to have a comprehensive understanding of how its various elements function together. Each individual piece plays a specific role in the overall operation, and recognizing how they interconnect is key to maintaining efficiency and avoiding potential issues. A deep knowledge of the components ensures that the system performs at its best for a longer period of time.

Identifying key components within the structure allows for easier diagnosis and troubleshooting. Every element, from the most basic to the most intricate, is designed to work seamlessly with others, making it vital to know how to recognize and differentiate between them. This awareness is particularly useful when attempting to identify potential faults or when conducting regular maintenance.

Understanding the function and positioning of each part makes it simpler to carry out repairs or replacements. With the right tools and knowledge, any issue can be addressed with confidence, ensuring that the system remains reliable and efficient. Familiarity with the essential components is the first step toward achieving optimal performance and longevity for your equipment.

How to Read the Parts Diagram

Reading a technical illustration is a crucial skill when it comes to understanding the internal structure of any system. These visuals provide a clear representation of how each component fits into the larger assembly, and interpreting them correctly can guide you through maintenance and repair procedures. The key is to familiarize yourself with the symbols and layout used to represent different elements, ensuring that you can identify them accurately when working on your equipment.

Typically, each part will be labeled with a reference number or code, allowing you to cross-reference it with a list of components for further details. Understanding this system of notation is vital for troubleshooting, as it helps pinpoint the exact location of any malfunctioning part. Once you recognize the basic symbols and their meanings, you can quickly navigate through any technical schematic with ease.

Moreover, pay attention to the way the components are arranged. Often, these drawings show how each element is connected or interacts with others. This can provide valuable insights into the flow of operations within the system, making it easier to isolate and resolve issues. By carefully studying the layout, you will be able to gain a better understanding of the system’s architecture and handle repairs more efficiently.

Essential Parts for Maintenance and Repairs

When maintaining or repairing any complex system, it is crucial to identify the core components that ensure smooth operation. These key elements are fundamental for the overall functionality, and their proper maintenance is vital for extending the lifespan of the equipment. Knowing which parts to focus on allows you to address potential issues before they become serious problems.

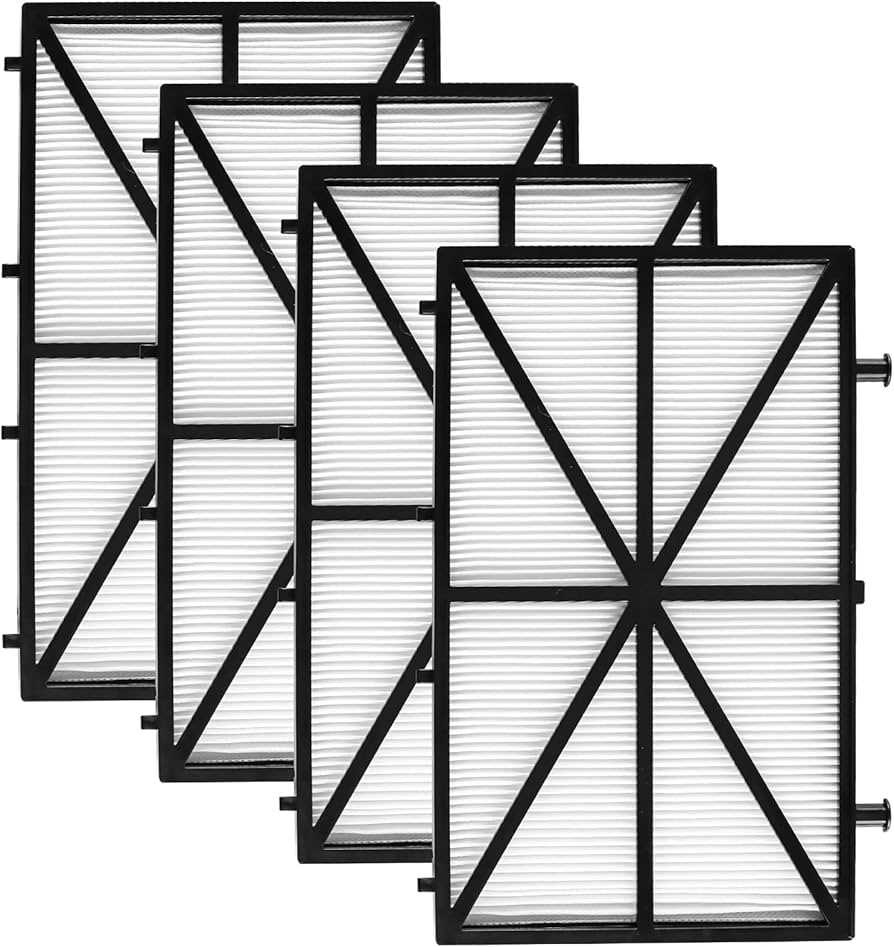

Regularly inspecting and replacing worn-out components helps prevent breakdowns and ensures that the system operates at peak efficiency. Some elements, like seals, filters, and pumps, are more prone to wear and should be checked frequently. These parts play critical roles in maintaining the flow of energy or liquid, and their failure can disrupt the entire system.

By focusing on high-impact parts that are central to the system’s operation, you can effectively reduce downtime and avoid costly repairs. Keeping track of these essential components, and having them on hand for quick replacements, will help maintain the integrity of the equipment. Proper care and attention to these key elements make it easier to handle unexpected malfunctions and keep the system running smoothly for a longer time.