Understanding the inner workings of your cleaning equipment is crucial for ensuring its longevity and efficiency. By gaining insight into its essential components, you can make informed decisions about maintenance and repairs. This knowledge empowers users to keep their systems running smoothly over time.

In this section, we will break down the various elements that contribute to the effective performance of your machine. From motors to filtration systems, each part plays a role in achieving the best results. A clear understanding of how these components interact with one another enhances overall performance.

Regular inspection and care of each part not only prolongs the lifespan but also prevents unexpected malfunctions. By recognizing potential issues early on, users can avoid costly repairs and keep their machines working at peak efficiency.

Understanding Cleaning Equipment Components

Effective cleaning relies heavily on the interaction of various internal elements that contribute to the overall functionality of the system. Recognizing the role of each component can significantly improve the way you handle maintenance and repairs. Knowledge of these essential parts helps ensure optimal performance, preventing potential issues before they arise.

Key Components That Drive Performance

At the core of any cleaning device are the motor, filtration system, and air pathways. Each of these plays a crucial role in maintaining the machine’s efficiency. The motor powers the entire system, while the filtration elements capture dust and particles, and the airflow mechanisms ensure that the system performs at full capacity.

Proper Care and Maintenance

To extend the life of your equipment, it’s important to regularly check and maintain these crucial parts. Frequent inspection of the motor and filters, along with proper cleaning techniques, will keep the system running smoothly. Addressing issues early prevents unnecessary wear and tear, ensuring the machine continues to perform at its best.

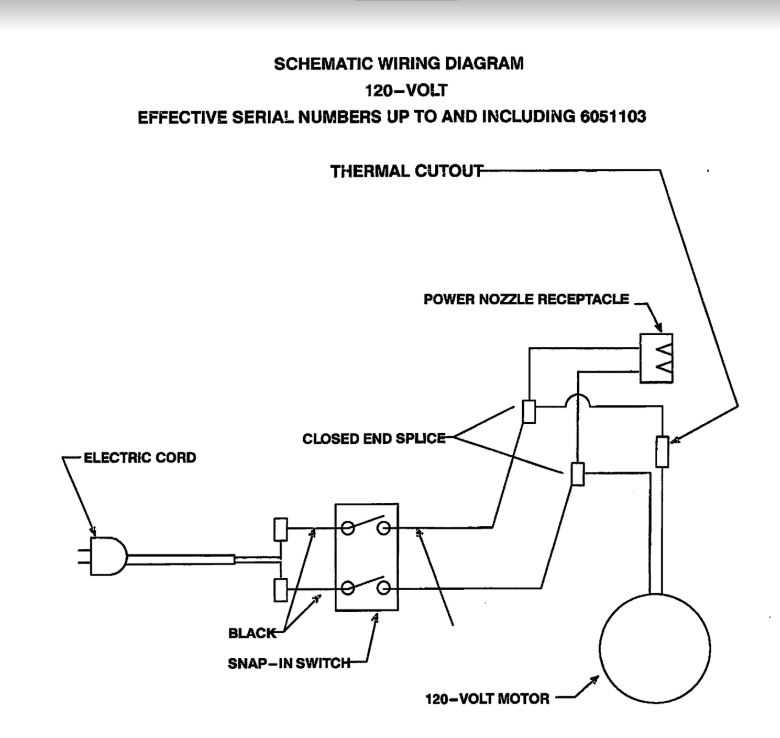

How to Identify Key Components in the Layout

Recognizing the critical elements in a machine’s internal setup is essential for troubleshooting and effective maintenance. By carefully examining the layout, you can pinpoint which parts influence overall functionality. This skill allows users to address issues more precisely and efficiently.

Steps to Identify Major Components

The first step is understanding the basic flow of the system. Start by locating the motor, as it is usually the central unit that drives the entire operation. Then, focus on the airflow pathways and filtration sections, as these are key to how the system captures and circulates air. Each component typically has a distinctive placement in the layout, which helps in quick identification.

Using the Layout to Troubleshoot

Once you identify the main parts, use the layout to trace any irregularities or potential faults. For example, if airflow is reduced, check the filters or hoses for blockages. By isolating specific sections, you can address the issue faster and avoid unnecessary disassembly. Efficient identification saves time and helps maintain optimal performance.

Maintaining Your Cleaning System Components

Proper upkeep of the internal elements in your cleaning device is crucial for preserving its efficiency and extending its lifespan. Regular maintenance ensures that all components continue to function optimally, preventing breakdowns and costly repairs. Understanding the specific care requirements for each part helps avoid common issues and improves overall performance.

Routine Cleaning and Inspections

Start by routinely checking the main components, such as the motor and filters, for wear or buildup. Keeping these parts clean is essential for maintaining maximum airflow and suction. Ensure all hoses and connectors are free from clogs or damage to ensure proper function. Regularly inspect the system’s filters, as dirty filters can hinder airflow and decrease performance.

Addressing Common Issues Early

Minor issues, if left unchecked, can lead to bigger problems down the line. By addressing any irregularities early–such as strange noises or reduced efficiency–you can prevent more serious damage. Always follow the manufacturer’s recommended maintenance schedule to ensure each part receives the necessary attention at the right time.