When it comes to maintaining and repairing outdoor power tools, understanding their structure and individual elements is key. A clear overview of how each part functions within the system can significantly improve your ability to troubleshoot and perform necessary repairs. Proper knowledge of these components ensures that you can keep your equipment in optimal condition for longer periods.

Efficient maintenance relies on being able to identify and understand the different parts of your tool. By learning how to break down each segment, you will gain confidence in carrying out both basic and more complex tasks. This guide aims to simplify the process, providing you with a detailed understanding of each component, its role, and how to identify it easily for maintenance and replacement.

Whether you are an experienced technician or a beginner, having access to a detailed breakdown of the system helps streamline repairs, saving both time and effort. By the end of this article, you will be better equipped to maintain and extend the life of your equipment.

Understanding the Equipment System

The multi-functional tool system is designed to provide flexibility and efficiency for various outdoor tasks. It allows users to attach different working units to a single power head, offering a versatile solution for everything from trimming to edging, blowing, and more. By understanding how this system is built, you gain insight into its modularity and how each component contributes to overall performance.

The Core Power Head

The core unit serves as the driving force behind the system, providing power to all the attached accessories. It is engineered to handle different attachments with ease, ensuring smooth operation regardless of the task. Its role is to house the engine, which provides the necessary power, as well as various controls that regulate the machine’s functions.

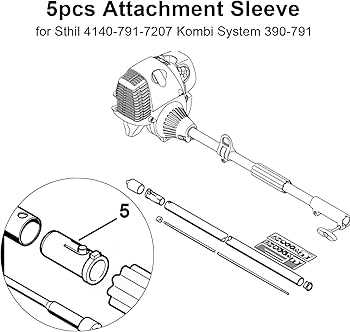

Attachments and Accessories

Each tool attachment is designed to serve a specific purpose, from trimming grass to clearing debris. These accessories connect seamlessly to the main unit, allowing the user to quickly switch between tasks. Understanding how these attachments function and how they are connected to the main body helps ensure proper use and maintenance, making your tool more efficient and versatile.

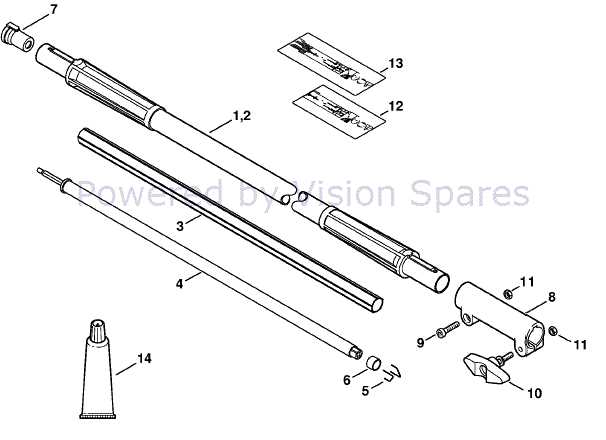

How to Read the Components Breakdown

Understanding the visual representation of a tool’s internal structure is essential for efficient repairs and maintenance. These breakdowns are designed to clearly show how individual components fit together and interact within the system. By studying these illustrations, users can easily identify parts that need attention or replacement, ensuring that their equipment operates smoothly.

Identifying Key Sections

In the illustration, each section of the tool is typically labeled with corresponding numbers and letters. These labels correlate with a detailed list that provides the exact name and part number for each item. Familiarizing yourself with the layout helps pinpoint the specific areas that require attention, making repairs faster and more precise.

Understanding Part Relationships

Components are often shown in relation to one another, which helps visualize how each part connects to the others. Understanding the interconnections between these elements allows for easier troubleshooting and more effective maintenance. Whether you’re replacing a single part or performing a more extensive repair, knowing how everything fits together will streamline the process.

Essential Maintenance Tips for Outdoor Power Tools

Proper maintenance is crucial for ensuring the longevity and optimal performance of your outdoor equipment. Regular care and timely adjustments can prevent common issues and keep the system running efficiently. By staying on top of maintenance tasks, users can avoid costly repairs and extend the life of their tools.

Cleaning and Lubrication

Regular cleaning is key to maintaining your equipment’s performance. After each use, make sure to remove debris, dirt, and grass buildup from both the motor housing and attachments. Lubricating moving parts ensures smooth operation and reduces wear, preventing mechanical failure over time. Pay special attention to the drive shaft and engine components, as these are essential for the overall function of the tool.

Inspection and Replacement of Key Components

Periodically inspect the critical components, such as the engine, air filters, and fuel lines, for any signs of wear or damage. Replacing worn parts promptly ensures that the equipment continues to operate safely and efficiently. Checking the attachment connections and fasteners also helps maintain stability and prevents accidents during operation.