Maintaining garden machinery can be a challenging task, especially when it comes to identifying and replacing various components. Whether you’re repairing or upgrading your equipment, knowing how to properly navigate and interpret technical diagrams is essential for smooth operation. Understanding the specific pieces that make up your machinery ensures that you can troubleshoot and carry out replacements without confusion.

When you familiarize yourself with the layout of all essential parts, it becomes easier to manage common issues, prolong the life of your equipment, and ensure efficient performance. This guide will walk you through the crucial elements of a typical machine, helping you identify components, understand their functions, and make informed decisions during repairs or maintenance.

Accurate knowledge of each part and its relationship within the system is invaluable. You’ll be equipped to solve problems more quickly and avoid unnecessary replacements. Whether you are a seasoned gardener or just starting out, this resource will help you maximize the functionality and longevity of your outdoor tools.

Understanding the Craftsman 5 HP Tiller Parts

Every piece of garden machinery is made up of various essential components that work together to ensure efficient operation. By understanding the roles of each part, you can troubleshoot problems more effectively and perform maintenance tasks with confidence. This section will help you become familiar with the key elements of the engine, transmission, and control systems, offering a comprehensive overview of the main components you may encounter during repairs or upgrades.

From the engine housing to the handles and wheels, each part serves a specific purpose that contributes to the overall functionality of the machine. Some parts control movement, others manage power, and certain components are responsible for safety and ease of use. Knowing how these pieces interact with one another is crucial for maintaining optimal performance.

In this guide, we’ll highlight the most commonly replaced elements, discuss their functions, and explain how to identify signs of wear or damage. With this knowledge, you’ll be able to keep your equipment running smoothly and efficiently, avoiding costly repairs or replacements by taking action early when needed.

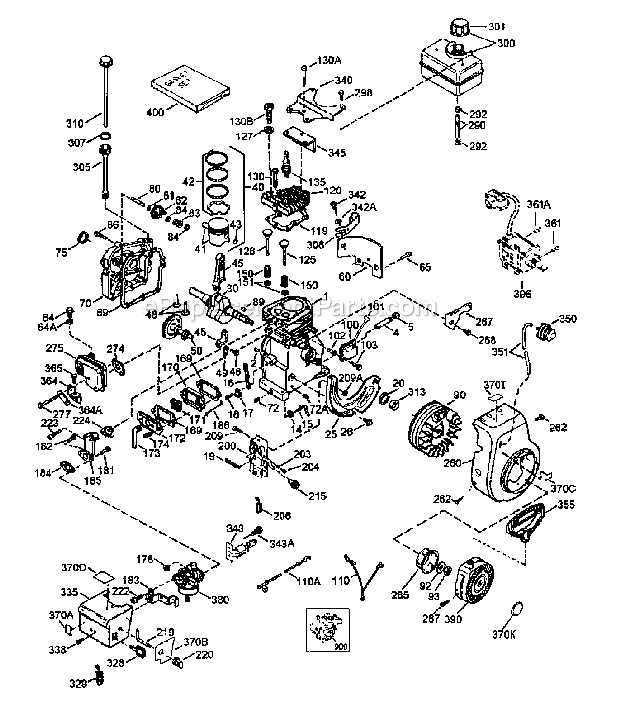

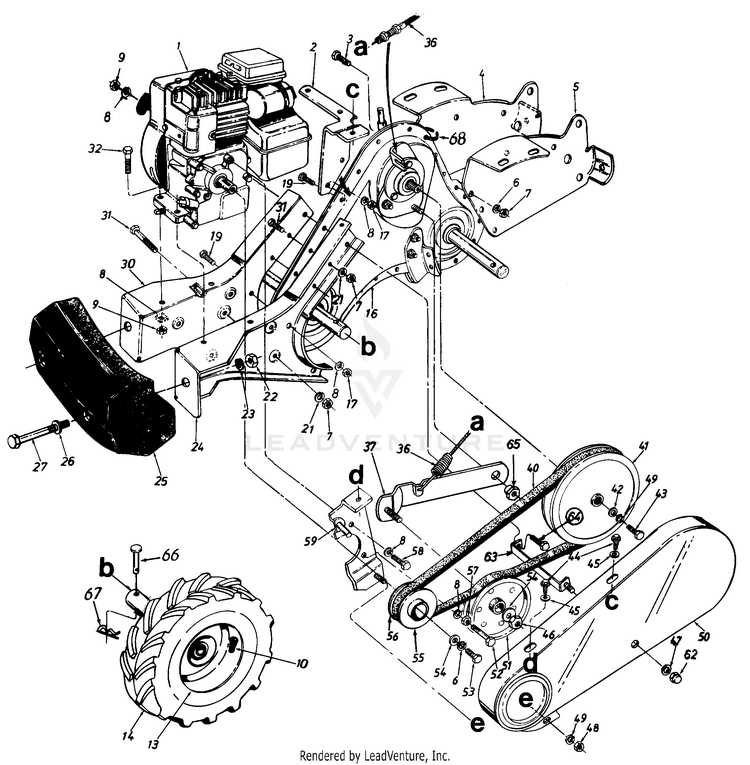

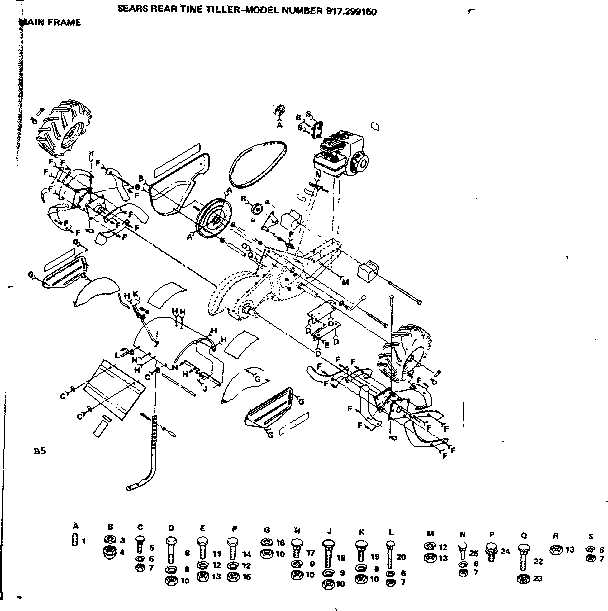

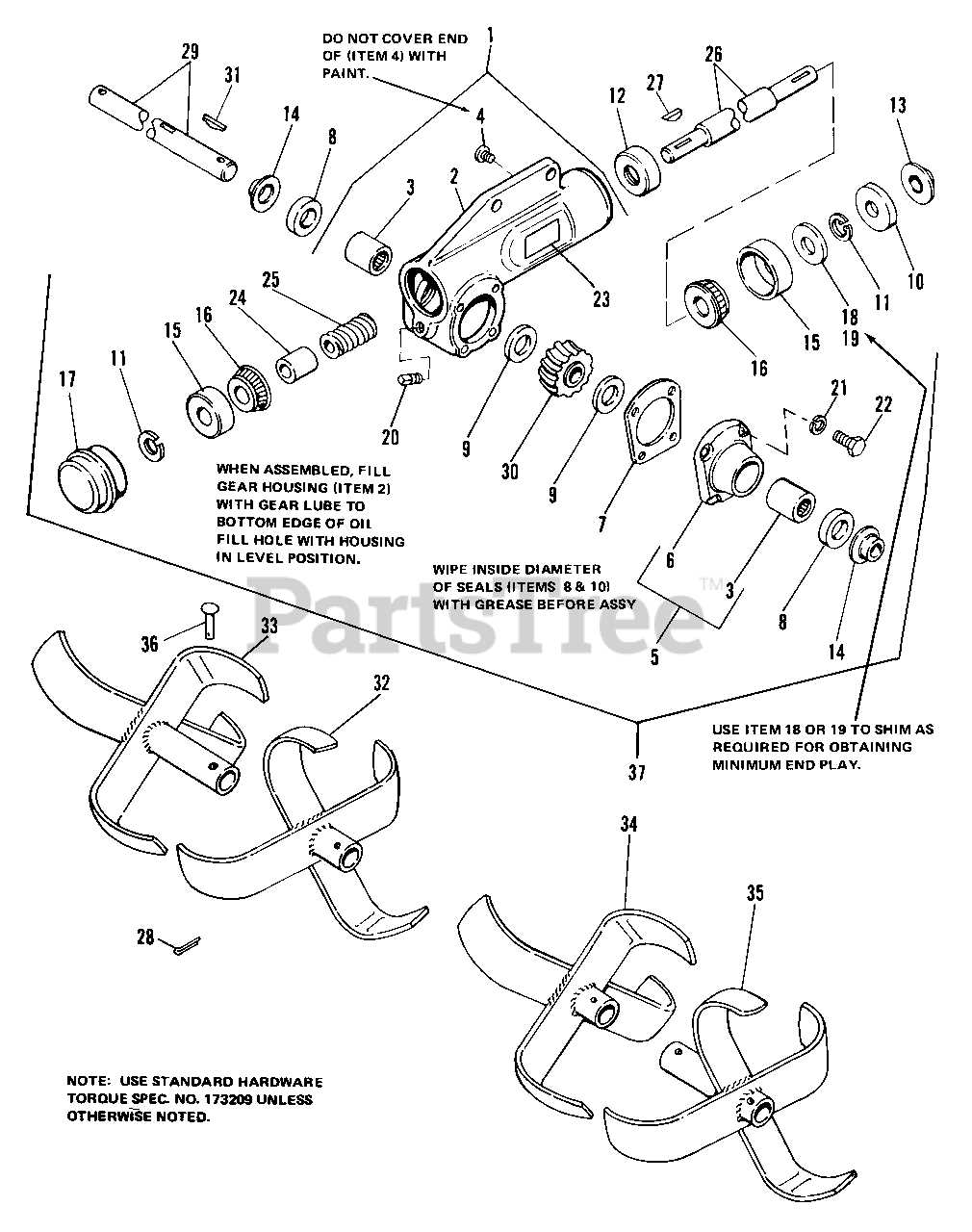

How to Read the Parts Diagram

Interpreting technical schematics is an essential skill when working with mechanical equipment. These visual guides provide a detailed view of all the components within the system, helping you locate and identify each element with ease. Understanding how to read these illustrations ensures you can find the exact part you need and comprehend its placement and function within the machine.

Breaking Down the Visual Elements

Each schematic typically includes clear labels and numbered references to indicate specific pieces. These numbers correspond to a list of components, often accompanied by detailed descriptions or part numbers. The layout is designed to show the relationship between different parts, with arrows or lines illustrating how each component connects to the others. Familiarizing yourself with these visual cues allows you to efficiently navigate the diagram and locate any part quickly.

Understanding Component Groupings

In many schematics, similar components are grouped together, such as gears, belts, or control mechanisms. This grouping helps you understand how systems within the machine are organized and how they work together. By focusing on these clusters, you can narrow down which parts are most likely to need attention based on the symptoms or issues you’re experiencing.

Common Replacement Parts for Craftsman Tillers

Maintaining garden equipment often requires replacing certain components due to wear and tear. While every machine is unique, some parts are more commonly replaced than others. Understanding which pieces are most likely to need replacement can help you stay prepared and keep your equipment running smoothly. In this section, we will explore the typical elements that need attention and how to recognize when it’s time to replace them.

Engines and Air Filters

The engine is the heart of any machine, and over time, it can experience issues related to power loss or inefficiency. One of the most common maintenance tasks is replacing air filters. These filters prevent dirt and debris from entering the engine, and when they become clogged, they can reduce performance or cause engine failure. Replacing the air filter regularly ensures that the engine runs at peak performance and reduces the risk of costly repairs.

Belts and Drive Systems

Belts are vital for transmitting power from the engine to other moving parts, such as wheels or gears. Over time, belts can stretch, crack, or snap, leading to decreased functionality or even complete breakdowns. Inspecting belts for wear and replacing them promptly helps maintain smooth operation. Additionally, components of the drive system, such as pulleys or drive shafts, may need replacement if they become worn out or damaged.