When working with power tools, understanding their individual components is crucial for ensuring smooth operation and effective maintenance. A clear visual representation of each element can make troubleshooting and repair tasks significantly easier, saving both time and effort. This guide will walk you through the various sections of your tool, helping you identify essential parts for optimal performance.

Proper knowledge of how different components interact will allow you to make informed decisions during repairs or upgrades. Whether you’re replacing worn-out pieces or simply checking for wear and tear, being familiar with the internal structure of your tool is key. In the following sections, we’ll dive into how to read these useful schematics and recognize the most important parts that need attention.

By understanding how the different elements of your equipment are organized, you can tackle maintenance tasks with confidence. The right visual reference makes all the difference when identifying issues and ensures your tool continues to perform at its best.

Understanding Power Tool Components

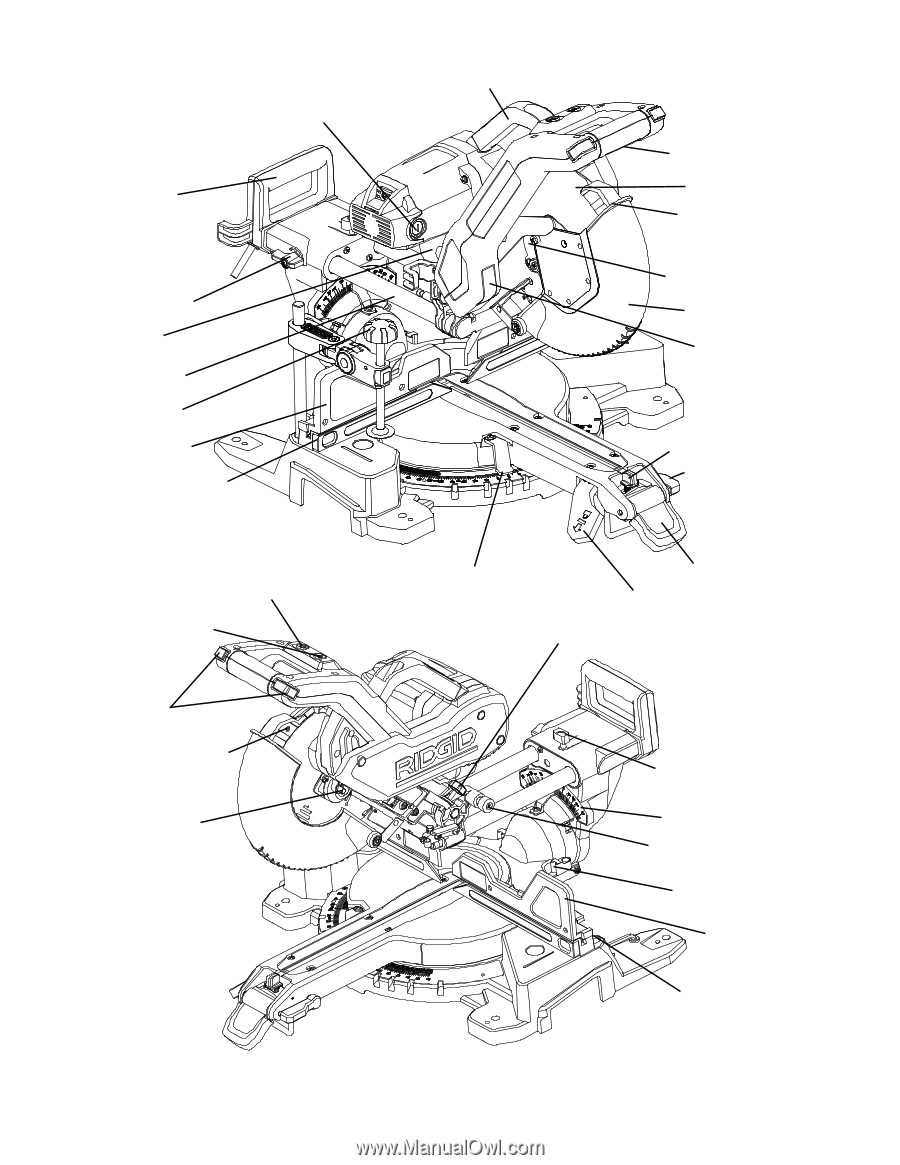

Each tool consists of several key elements that work together to perform specific tasks. Familiarity with these individual sections helps users not only in efficient operation but also in diagnosing issues or performing necessary upgrades. In this section, we will explore the essential components of your cutting equipment and their roles in ensuring smooth functionality.

Key Mechanisms of the Cutting System

The primary function of any cutting equipment relies on its cutting mechanism. This involves the blade, motor, and supporting structures that facilitate smooth and precise cuts. The motor is responsible for generating power, while the blades are designed to handle different materials with ease. Understanding how these elements are arranged will allow users to quickly identify potential issues like blade wear or motor strain.

Supporting Structures and Safety Features

Beyond the cutting system, several additional components ensure the tool remains stable, safe, and easy to use. Support arms, clamps, and dust collection systems play vital roles in securing materials during operation and maintaining a clean workspace. Safety features, such as blade guards and locking mechanisms, prevent accidents and improve user confidence while operating the tool.

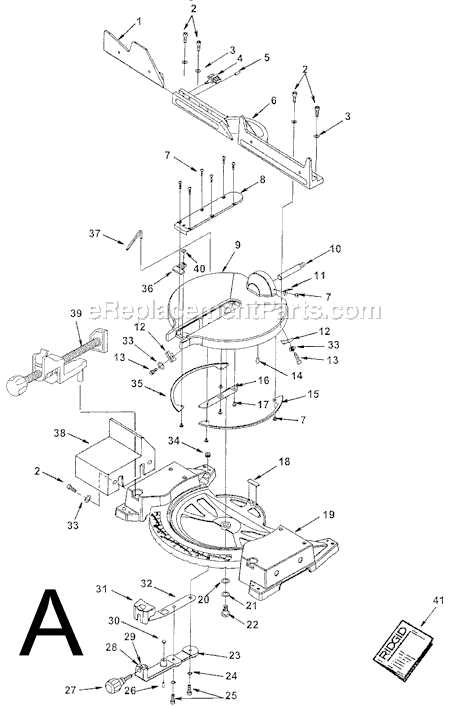

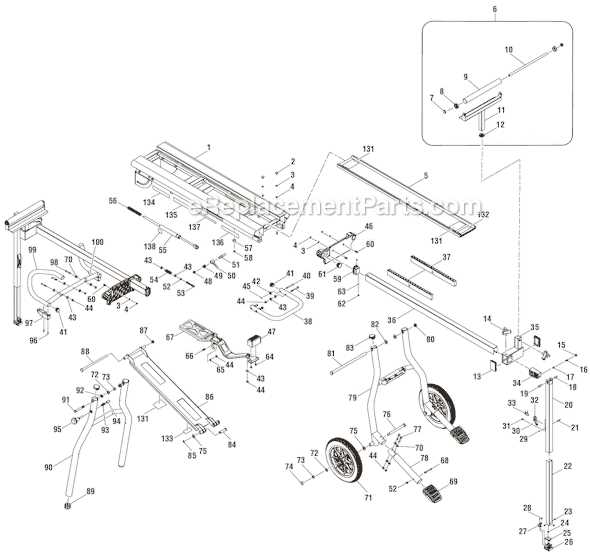

How to Identify Key Parts in the Diagram

Understanding how to read and interpret technical illustrations of your tool is essential for maintenance and repair. These visual representations offer a detailed view of the components, making it easier to locate and identify specific sections. By recognizing the labels and understanding their placement, you can quickly navigate through the diagram and pinpoint the necessary elements for any task.

Recognizing Essential Components

In most illustrations, the core components such as the motor, blade holder, and adjustment mechanisms are typically highlighted with distinct markings or shading. Knowing how these parts are connected will help you understand the function of each element within the tool. Look for the sections that are most likely to wear out or require frequent inspection, such as the gearing system or safety locks.

Utilizing Labels and References

Diagrams usually come with helpful labels and reference numbers that guide users to specific components. These references are crucial when ordering replacement parts or troubleshooting. Pay attention to any highlighted text or arrows indicating the flow of movement or energy within the tool, as they help to visualize the overall function of each section.

Common Maintenance Tips for Power Tools

Regular maintenance is essential to keep your equipment running efficiently and to extend its lifespan. By performing routine checks and minor repairs, you can ensure optimal performance and avoid costly breakdowns. This section provides practical tips to help you maintain your cutting tool and address common issues before they become major problems.

Blade Maintenance and Cleaning

One of the most important aspects of tool upkeep is maintaining the cutting element. Regularly check the blades for signs of wear, corrosion, or buildup of debris. Clean them after each use to prevent material accumulation, which can affect performance. If you notice any dullness or chips, it may be time to sharpen or replace the blade to ensure clean, precise cuts.

Lubrication and Motor Care

To ensure the internal components continue to function smoothly, apply lubrication to moving parts such as gears and pivot points. This helps reduce friction and prevents premature wear. Additionally, make sure to inspect the motor regularly for any signs of overheating or dust accumulation. Keeping the motor clean will promote its efficiency and prevent overheating, which can lead to malfunctions.