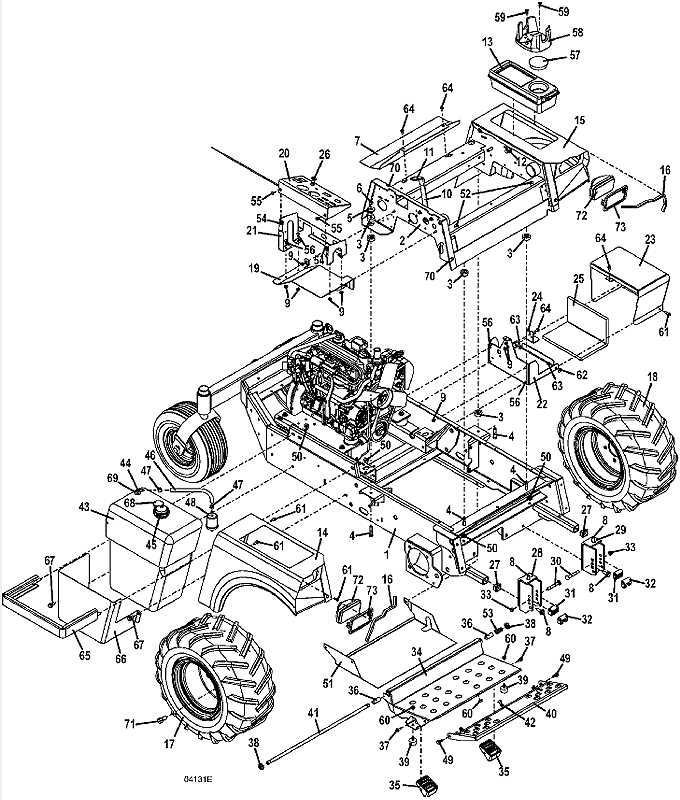

Proper maintenance of your utility vehicle requires a solid understanding of its internal structure. To perform repairs, upgrades, or replacements, it’s crucial to know how each component fits together and functions. Access to clear, accurate visual references simplifies this process, ensuring that any issues can be addressed efficiently.

By examining detailed illustrations, you can identify various vehicle elements, from the engine to suspension systems, with ease. This knowledge not only speeds up repair times but also helps in selecting the right replacement parts when needed. A well-informed approach minimizes the risk of errors during maintenance and extends the longevity of your equipment.

Whether you’re a seasoned technician or a first-time owner, understanding these schematics is a valuable skill. With the right tools and the ability to navigate these detailed guides, you’ll be prepared to handle most mechanical challenges your vehicle might present.

Understanding the Kubota RTV900 Parts

To maintain and repair your utility vehicle, it’s essential to become familiar with its various components and how they interact. Knowing the key elements of the machine and their functions will allow for more effective troubleshooting and quicker repairs. Whether you’re replacing worn-out parts or upgrading certain systems, understanding the vehicle’s internal structure is the first step toward efficient maintenance.

Key Vehicle Components

Each vehicle is made up of several major systems, including the engine, transmission, suspension, and electrical components. Recognizing how these systems work together helps pinpoint issues and ensures the correct part is selected when a replacement is necessary. Engine parts, such as the air filter, spark plugs, and belts, are crucial for optimal performance, while the transmission system ensures smooth operation of the vehicle’s gears. The suspension system is responsible for maintaining stability and comfort while driving over uneven terrain.

How Parts Work Together

Understanding how each component interacts is vital for identifying the root causes of malfunctions. For instance, a problem with the fuel system could affect engine performance, while issues with the electrical system may impact the vehicle’s lights and power functions. Knowing the connection between these systems allows for better diagnosis and more precise repairs. The ability to visualize how each part fits into the overall vehicle structure is an invaluable skill when maintaining or restoring machinery.

How to Read the RTV900 Parts Diagram

Understanding how to interpret visual schematics is an essential skill for anyone working with complex machinery. These illustrations provide a detailed overview of a vehicle’s components, showing how each element is connected. By learning to read these technical guides, you can quickly locate parts and identify potential issues, which makes repairs and maintenance much more efficient.

The key to effectively using these visual references lies in recognizing the symbols and part numbers used. Each component is typically marked with a unique identifier, allowing you to cross-reference it with a parts list or catalog. This ensures you’re selecting the correct replacement items and helps you understand how the parts fit together within the overall system. It’s important to become familiar with the layout of the diagram, so you can quickly navigate through the various sections for specific details.

Once you understand the symbols and layout, you’ll be able to track the flow of systems like the engine, transmission, or electrical wiring. These diagrams provide a clear path for troubleshooting, allowing you to pinpoint exactly where problems may lie. Mastering the reading of these technical drawings is crucial for maintaining your vehicle in top condition and ensuring that repairs are done efficiently and accurately.

Essential Kubota RTV900 Components for Repair

For successful maintenance and repair of your utility vehicle, knowing which key systems and elements require attention is crucial. Understanding the most common areas that need repairs can save both time and money. Regularly inspecting vital components can help prevent major failures and keep your vehicle running smoothly over time. Familiarity with these critical systems enables you to take prompt action when something goes wrong, preventing larger issues from arising.

Engine and Powertrain

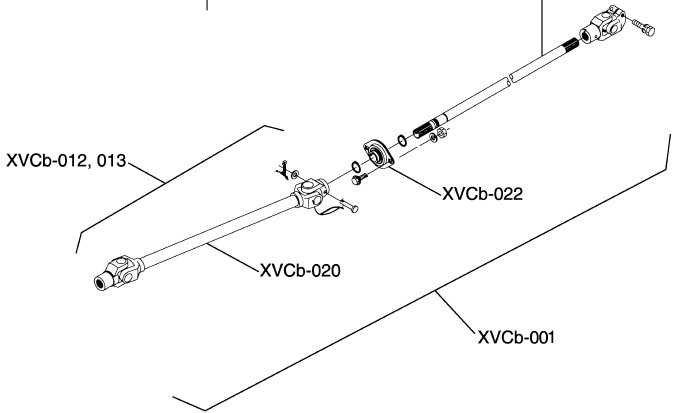

The engine is the heart of any vehicle, and its components are among the most commonly repaired parts. Essential elements like the fuel system, air filters, and spark plugs should be checked regularly. Additionally, the powertrain–comprising the transmission, driveshafts, and differential–requires periodic inspection to maintain smooth performance. If any part begins to wear down or malfunction, immediate attention is necessary to prevent further damage to the vehicle.

Suspension and Steering

The suspension system is integral to a smooth ride and proper handling, especially when driving over rough terrain. Worn-out shock absorbers, damaged suspension arms, or faulty steering components can significantly affect the vehicle’s performance and safety. Regular checks of these systems are essential, as replacing components early can prevent more costly repairs down the road. Strong, well-maintained suspension parts ensure that your vehicle stays in control, even in challenging conditions.

Tip: Always refer to the specific parts catalog or reference material to ensure that you’re using the correct components for replacement. Using the wrong parts can compromise your vehicle’s efficiency and longevity.