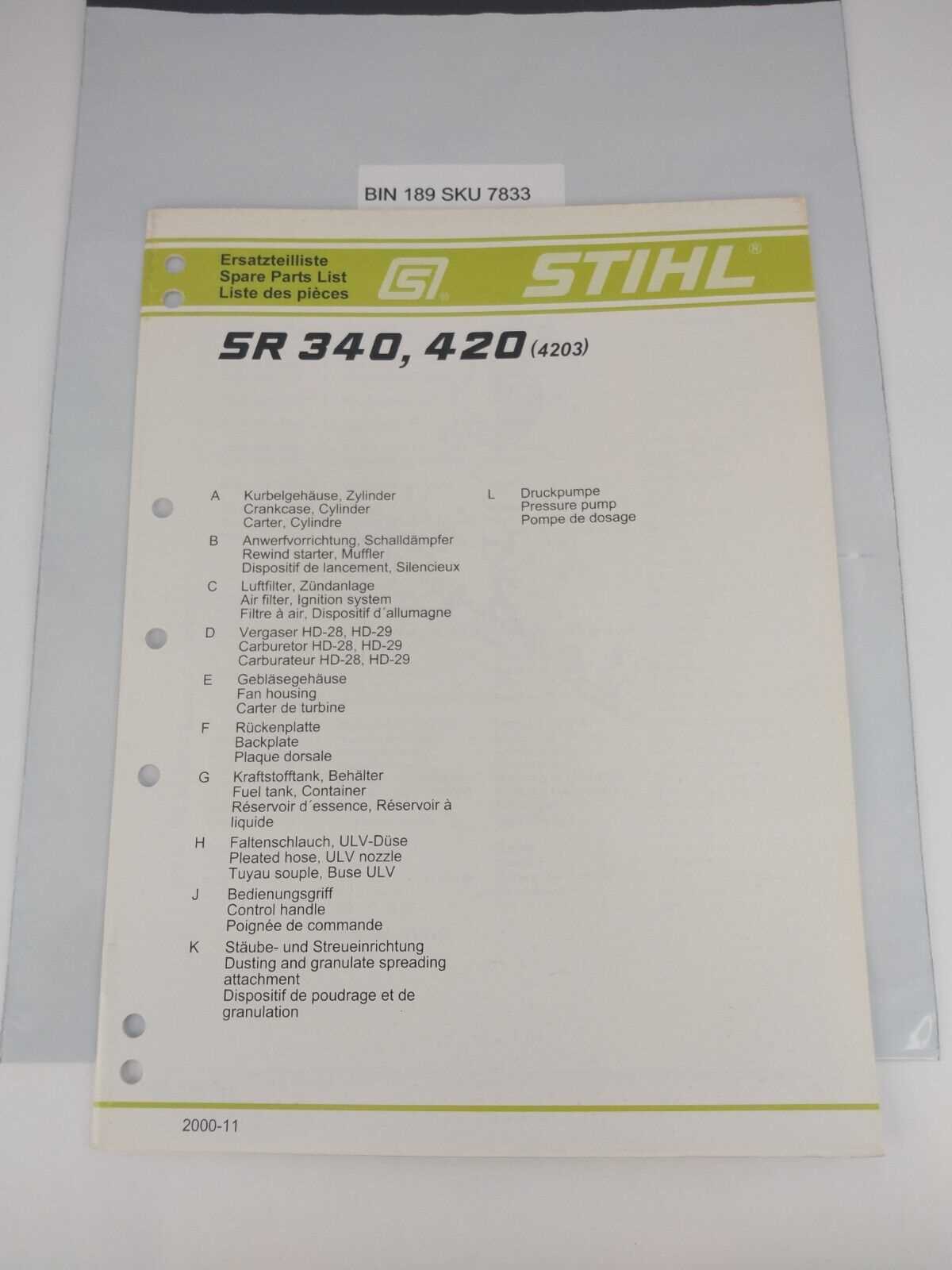

For effective maintenance and repairs, a clear understanding of the machine’s internal structure is essential. Knowing how each individual component fits together ensures smooth operation and prevents unnecessary breakdowns. This knowledge is key when it comes to maintaining optimal functionality and extending the lifespan of your equipment.

Identifying the specific elements involved in the assembly process will guide you in recognizing wear or potential issues. Whether you are replacing worn-out parts or simply performing routine checks, being able to refer to a detailed representation of the unit will greatly enhance your efficiency and accuracy.

With the right visual guide, identifying which parts require attention becomes much easier. It simplifies the process of assembly and disassembly, allowing for quick repairs and less downtime. Having a comprehensive understanding of the entire structure not only speeds up maintenance but also minimizes the risk of mistakes during service tasks.

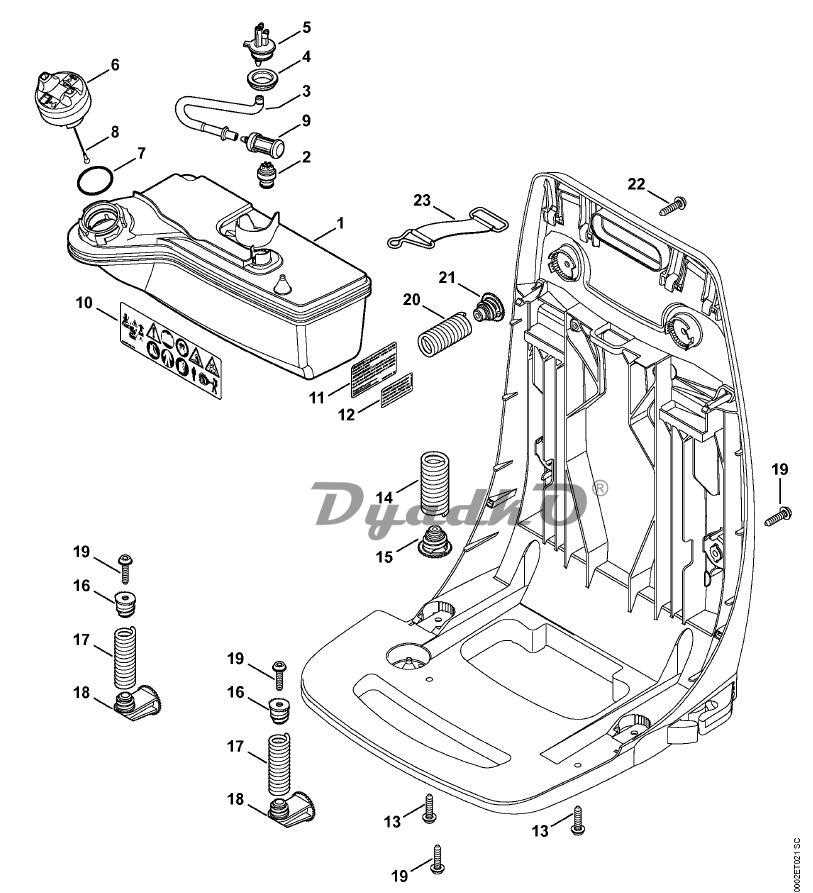

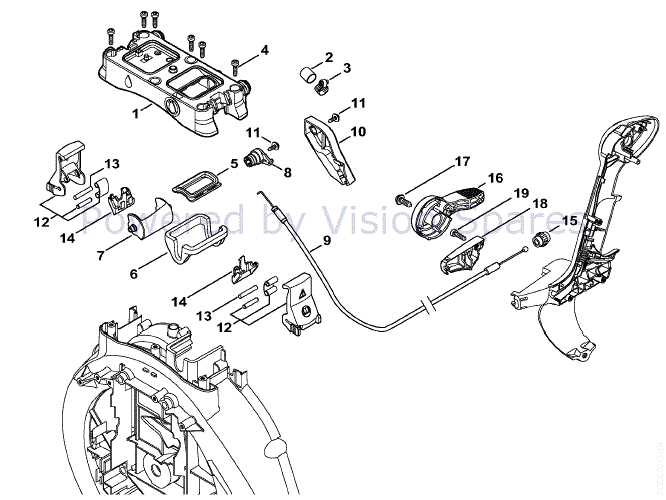

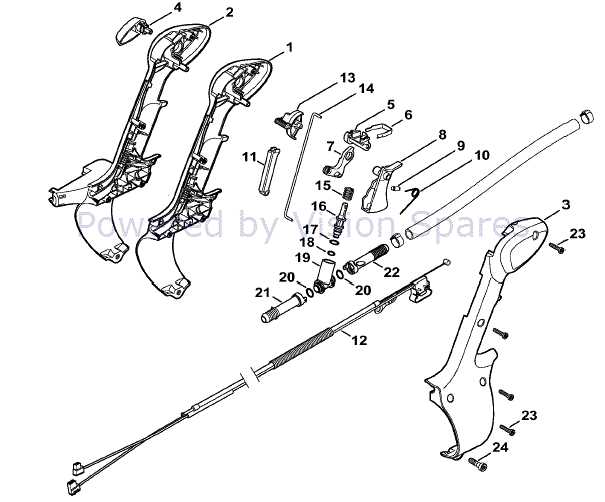

Exploded View Overview

Understanding the full assembly of your machine is vital when performing maintenance or troubleshooting. An exploded view provides a detailed visual breakdown, allowing you to easily identify each individual component and how they interact within the larger structure. This type of visual aid is essential for anyone looking to perform repairs or routine checks with precision and confidence.

Key Features of the Exploded View

The exploded view offers a comprehensive representation of the equipment, with each part clearly labeled. This allows users to quickly locate and assess the various components without having to disassemble the entire unit. With this detailed guide, users can more effectively spot areas requiring attention, from worn-out components to those in need of adjustment or replacement.

Benefits for Maintenance and Repair

By providing a clear layout of all parts, an exploded view simplifies the repair process. It helps users understand the relationship between parts and identify the correct order for assembly and disassembly. This visual clarity also reduces the risk of errors, ensuring that repairs are made efficiently and accurately, saving both time and effort.

Key Components of the SR 450 Model

Every piece of machinery consists of several integral elements that work together to ensure smooth operation. Understanding these components is crucial for both maintenance and repair, as each part plays a specific role in the overall function. Identifying these elements helps users to better manage their equipment and address any issues that may arise during its usage.

Power and Engine System

The power system is at the heart of the machine, driving its performance. This includes the engine components responsible for generating the necessary power to operate the unit effectively. Proper maintenance of these key elements ensures the engine runs smoothly, reducing the likelihood of performance drops or malfunctions.

Operational and Support Elements

Beyond the engine, the operational components such as the drive system, fuel lines, and exhaust system are essential for smooth functionality. Each of these elements must work in harmony to allow efficient operation and avoid any disruptions during use. Regular inspection of these areas ensures that the machine functions as intended, maintaining high efficiency and reliability.

How to Use the Visual Guide Effectively

Utilizing a detailed visual representation can greatly enhance your ability to identify and understand the components within your equipment. By following the guide, you can easily pinpoint specific parts, understand their roles, and assess their condition. This method not only saves time but also ensures that repairs or replacements are done accurately.

Start with an overall view to familiarize yourself with the machine’s layout. Understanding the arrangement of key elements is the first step in using the visual guide effectively. Once you have a sense of the big picture, focus on the specific areas that require attention or replacement.

Cross-reference with your equipment to match the components in the guide with what you see in your machine. This helps you identify exact parts and their positions, ensuring you address the right areas. By doing so, you reduce the risk of mistakes and improve the efficiency of your maintenance work.