When working with outdoor machinery, knowing the structure and functions of its various components is essential. Identifying each element’s role ensures smoother operation and simplifies maintenance. For anyone managing garden equipment, having a clear overview of how these parts interact can save both time and effort during repairs or upgrades.

Breakdowns are often due to worn or damaged components, making it crucial to recognize the exact part that needs attention. By examining the layout and understanding the connection between each element, users can avoid unnecessary replacements and repairs.

Whether you’re a professional landscaper or a home gardener, familiarity with your equipment’s internal setup empowers you to take control of its upkeep. A comprehensive knowledge of its assembly can help in troubleshooting and ensuring that everything is functioning as it should.

Understanding Lawn Equipment Components

Every piece of outdoor machinery is made up of a variety of components that work together to achieve optimal performance. Understanding how these elements function individually and collectively allows users to keep their equipment running smoothly. When you are familiar with the construction and roles of each part, troubleshooting becomes easier, and maintenance can be performed more efficiently.

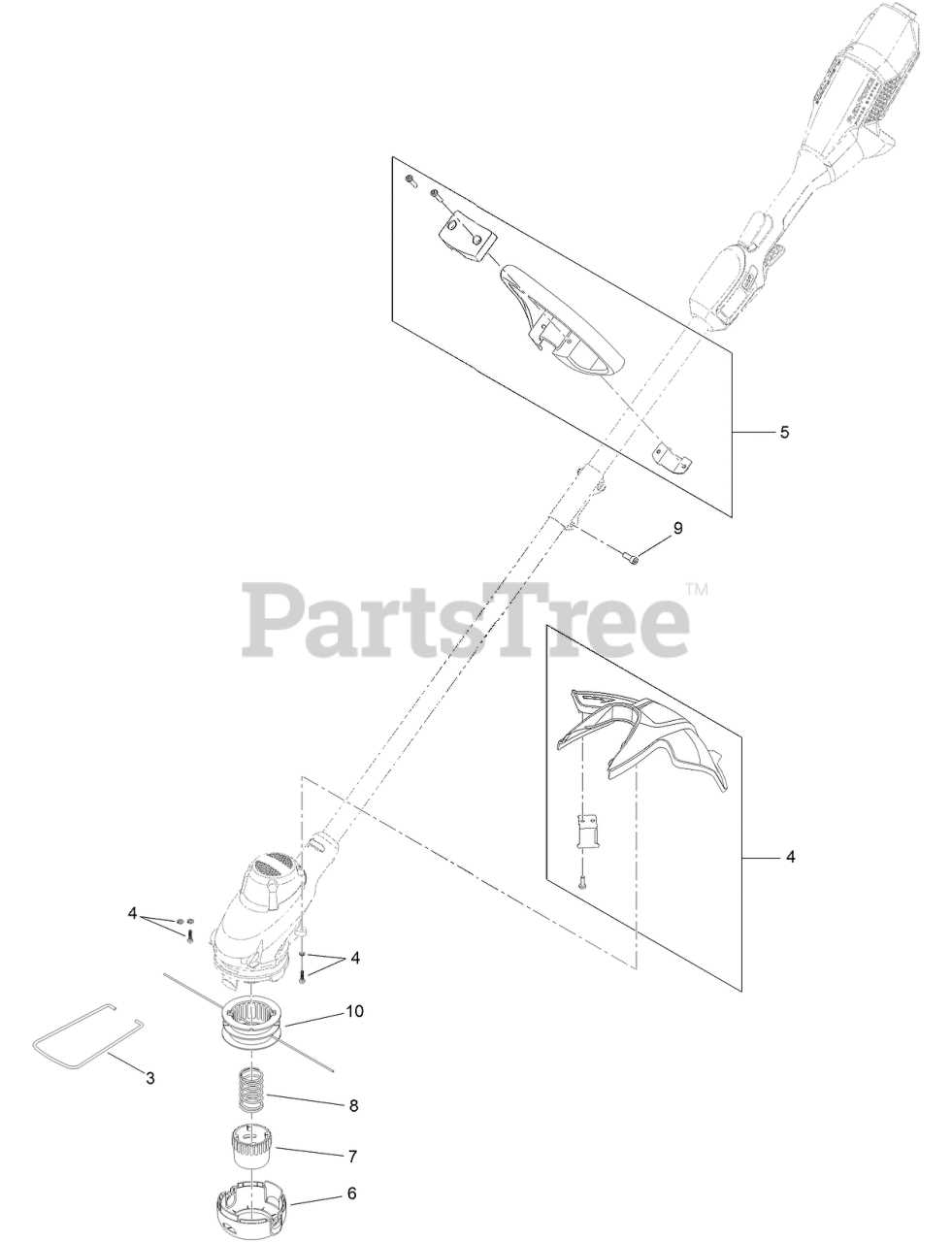

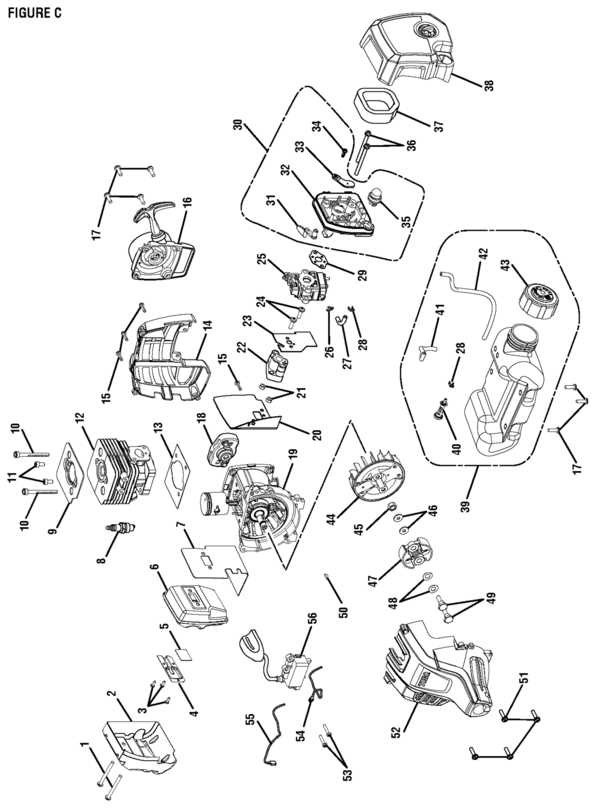

Key Components to Identify

The internal structure of lawn equipment typically includes essential elements such as the motor, housing, cutting mechanism, and handle. Each plays a vital role in the overall function of the device. The motor powers the system, while the cutting mechanism is responsible for the actual work. Proper housing ensures that all parts stay securely in place, and the handle provides the user with control. Knowing these core elements helps in diagnosing issues or replacing faulty parts when necessary.

How Components Interact

Each element within the system has a specific job, but their functions are interconnected. For example, a motor may struggle to function correctly if it is not adequately connected to the power source. Similarly, wear and tear on the cutting mechanism can cause a chain reaction, affecting the overall efficiency. By understanding how the parts work together, users can better maintain their equipment, preventing small issues from becoming costly repairs.

Exploring the Key Parts of a Trimmer

Outdoor equipment often relies on a variety of components that serve specific functions. Understanding the key elements that make up the system can improve both performance and longevity. Each piece contributes to the overall efficiency, and recognizing their roles helps users troubleshoot issues more effectively or make repairs as needed.

Power System and Motor

The motor is the heart of the equipment, providing the necessary energy to drive the cutting mechanism. Typically, the power source can be either gas-powered or electric, depending on the model. The efficiency of the motor affects the overall strength and reliability of the device. Ensuring proper maintenance of the motor can prevent many operational problems.

Cutting Mechanism and Accessories

The cutting head and its accessories are crucial for achieving the desired result. The cutting system usually includes elements such as the string, blades, or other attachments that perform the actual work. Regular inspection of the cutting components is important for maintaining sharpness and functionality, ensuring that they effectively tackle grass, weeds, or other materials.

How to Identify Lawn Equipment Issues

Understanding how to spot potential problems in outdoor machinery is essential for maintaining its performance. Regularly checking the equipment for signs of wear or malfunction can prevent larger issues and extend its lifespan. Knowing what to look for when problems arise can save both time and money.

Common issues often stem from a few key areas. Here are some symptoms to watch for:

- Unusual Noises: If the motor makes strange sounds or the equipment is vibrating more than usual, there may be a loose part or internal damage.

- Loss of Power: A noticeable reduction in power can be caused by a malfunctioning motor or a clogged cutting system.

- Difficulty Starting: If the equipment is hard to start, it could be an issue with the power source, spark plug, or fuel line.

- Uneven Cutting: When the cutting mechanism fails to deliver even results, it could indicate problems with alignment or dull blades.

By paying attention to these symptoms, users can identify issues early on and take appropriate action.