Efficient maintenance and repair of agricultural machinery require a clear understanding of its internal structure and essential elements. A visual guide can help operators and mechanics identify key components, making it easier to address any issues that arise. This is particularly important for individuals who rely on their machines for day-to-day operations and need to keep them running smoothly.

By familiarizing yourself with the detailed arrangement of the various components, it becomes easier to diagnose problems, locate specific parts, and perform routine upkeep. The visual reference serves as a valuable tool for both beginners and experienced professionals, ensuring that every aspect of the machinery is properly maintained and serviced.

Having access to such a guide can significantly improve the efficiency of your maintenance tasks, allowing you to quickly locate parts that need attention. Whether you are troubleshooting a malfunction or planning routine maintenance, a comprehensive layout guide is an essential resource for any technician or enthusiast.

Understanding the Tractor Layout

Knowing the configuration of key components in agricultural machinery is crucial for effective operation and maintenance. This section explores the overall arrangement of the machine’s elements, offering a comprehensive overview of its internal structure. By understanding the layout, users can efficiently locate parts that require attention and better manage repair and maintenance tasks.

Key Sections of the Machine

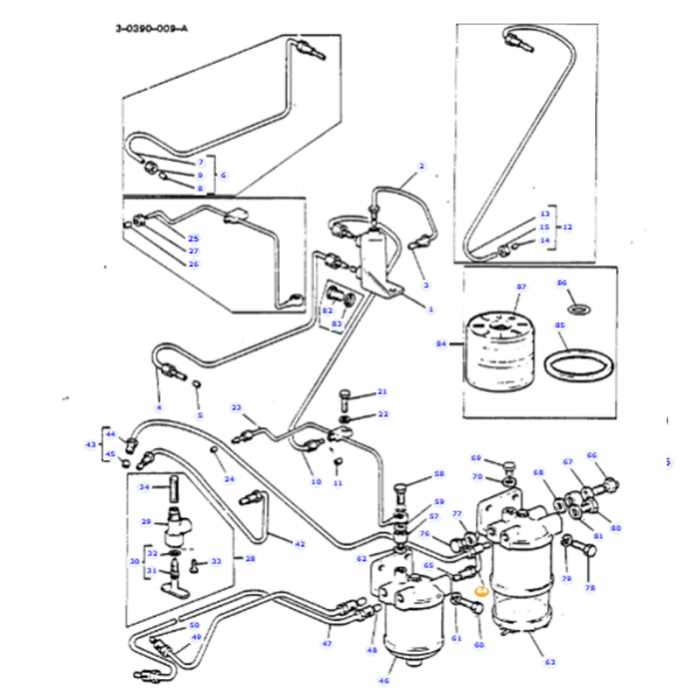

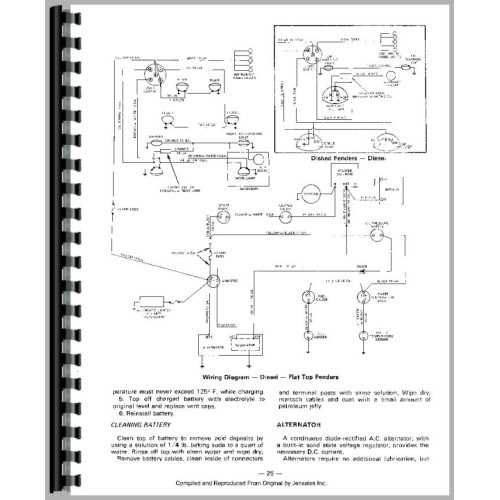

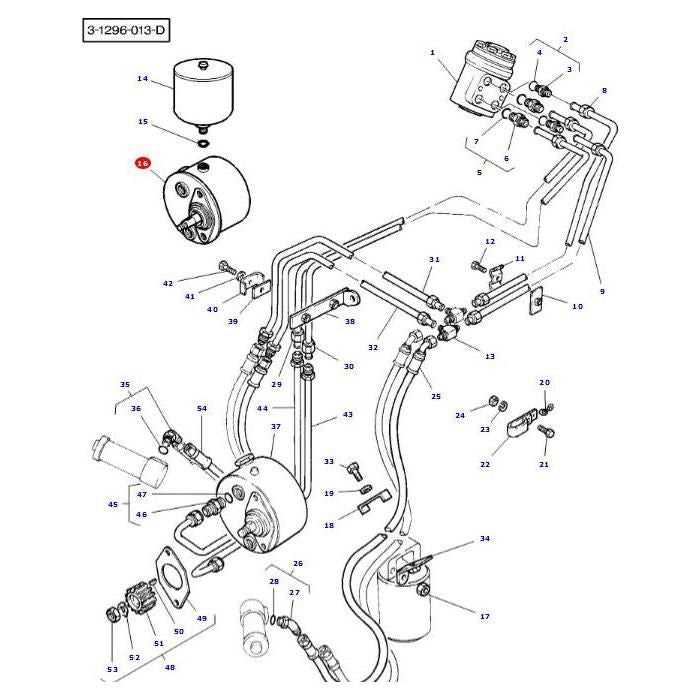

The machinery is divided into distinct sections, each with its own specific role. The engine compartment houses the core power-producing components, while other sections, such as the transmission and hydraulic system, ensure smooth operation and functionality. Familiarity with these sections allows operators to quickly pinpoint any issues and maintain the equipment more effectively.

Essential Components for Maintenance

Some components are more critical than others when it comes to performance and longevity. The fuel system, for example, requires regular checks to avoid contamination or blockage, while the cooling system must be inspected to prevent overheating. Understanding which parts are essential for keeping the machine in peak condition can help prioritize maintenance tasks and reduce downtime.

How to Use the Layout Guide Effectively

To maximize the usefulness of a visual reference for machinery, it is important to understand how to navigate the guide and interpret the details. The correct approach ensures that users can identify specific components quickly, which is essential for both troubleshooting and maintenance. Proper use of the guide will streamline repair efforts and make overall management more efficient.

Reading and Interpreting the Visual Guide

The first step in utilizing the reference effectively is understanding its layout. Each component is labeled and positioned in a way that reflects its real-world placement in the machine. By following the flow from one section to the next, users can systematically identify areas that need attention. Pay special attention to the numbering system or any symbols, as these provide additional context for the parts listed.

Locating and Replacing Components

Once you’ve identified a specific part or section, the next task is to find the corresponding replacement or perform necessary repairs. The guide often includes specifications and descriptions of the components, which can assist in selecting the correct replacement. Always ensure you’re working with the most accurate and up-to-date information to avoid errors during repairs.

Key Components of the Tractor

Every machine relies on several core elements to function properly. These essential components work together to ensure smooth operation, power generation, and task execution. Understanding the main sections of a machine is crucial for any operator, as it helps identify potential issues and perform necessary maintenance to keep the machinery running efficiently.

The engine, transmission, and hydraulic systems are the fundamental parts that enable movement and power delivery. The engine generates the power needed for the machine, while the transmission ensures that this power is transferred efficiently to the wheels or implements. The hydraulic system controls the lifting and movement of attachments, making it one of the most important features for many agricultural tasks.

In addition to these primary systems, the fuel system and cooling system are essential for maintaining operational longevity. The fuel system ensures that the engine receives the proper amount of fuel, while the cooling system prevents overheating during extended use. Regular checks and maintenance of these components are key to avoiding costly repairs and ensuring consistent performance.