Maintaining lawn care equipment requires a thorough understanding of its internal components. When problems arise, knowing the structure and layout of key elements can significantly simplify the repair process. Having a clear guide to these elements ensures that you can identify what needs attention and how to properly replace or fix them.

In this section, we will break down the essential elements that make up your lawn tool, helping you understand each function. With the right knowledge, diagnosing issues and performing maintenance becomes much easier, enabling you to extend the life of your equipment.

Whether you’re troubleshooting a malfunction or simply performing routine upkeep, understanding the inner workings of your machine is vital. With this insight, you can proceed confidently and efficiently, ensuring your equipment remains in top condition for years to come.

Understanding the Lawn Tool Components

To properly maintain any lawn care equipment, it’s crucial to familiarize yourself with the key components that enable its operation. These tools are designed with various parts that work together to ensure smooth performance. By recognizing each part’s role, you can identify issues and carry out necessary repairs with greater precision.

Each piece, from the cutting mechanism to the power source, plays a vital role in ensuring the tool functions correctly. Understanding the placement and connection of these elements allows for efficient troubleshooting and upkeep. This knowledge not only simplifies repairs but also improves the overall lifespan of the equipment.

Having a clear understanding of the internal setup of your tool helps when you need to replace worn-out or malfunctioning parts. It ensures that each part is in its correct position, and any discrepancies can be quickly addressed, preventing further damage or inefficiency in the system.

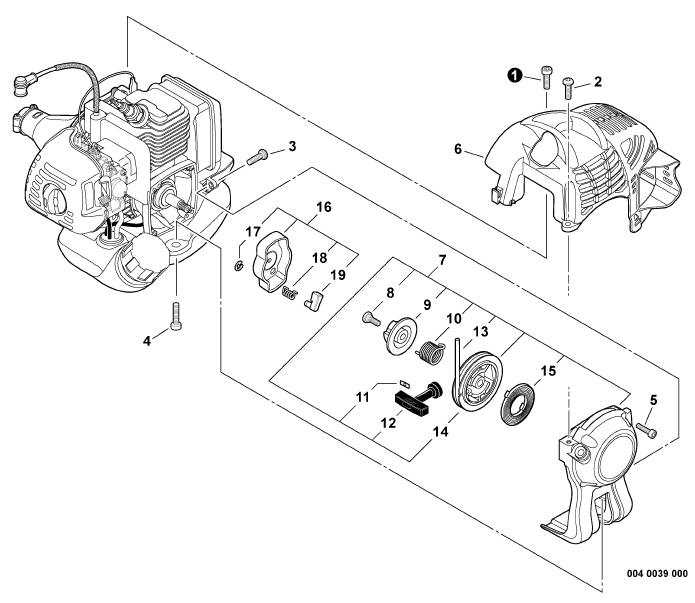

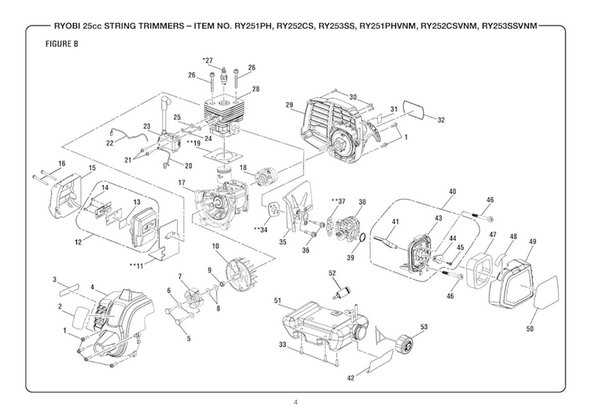

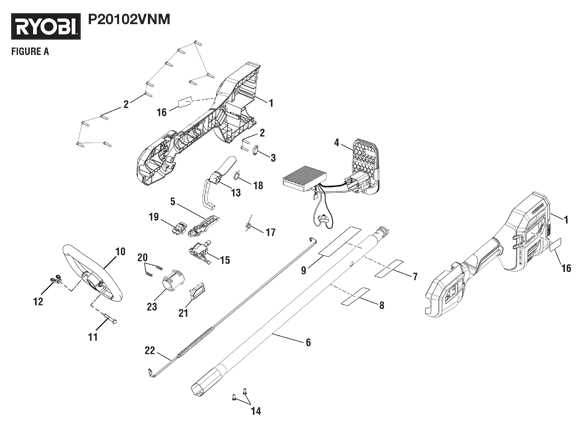

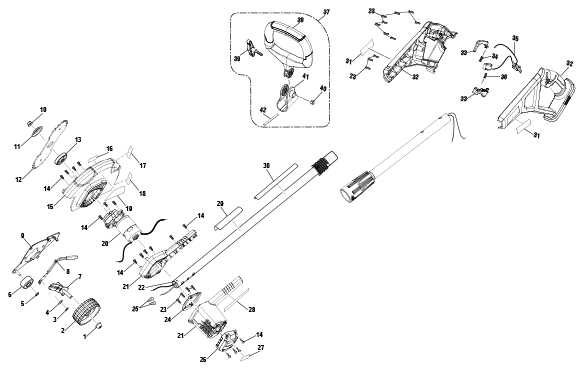

How to Identify Parts in the Diagram

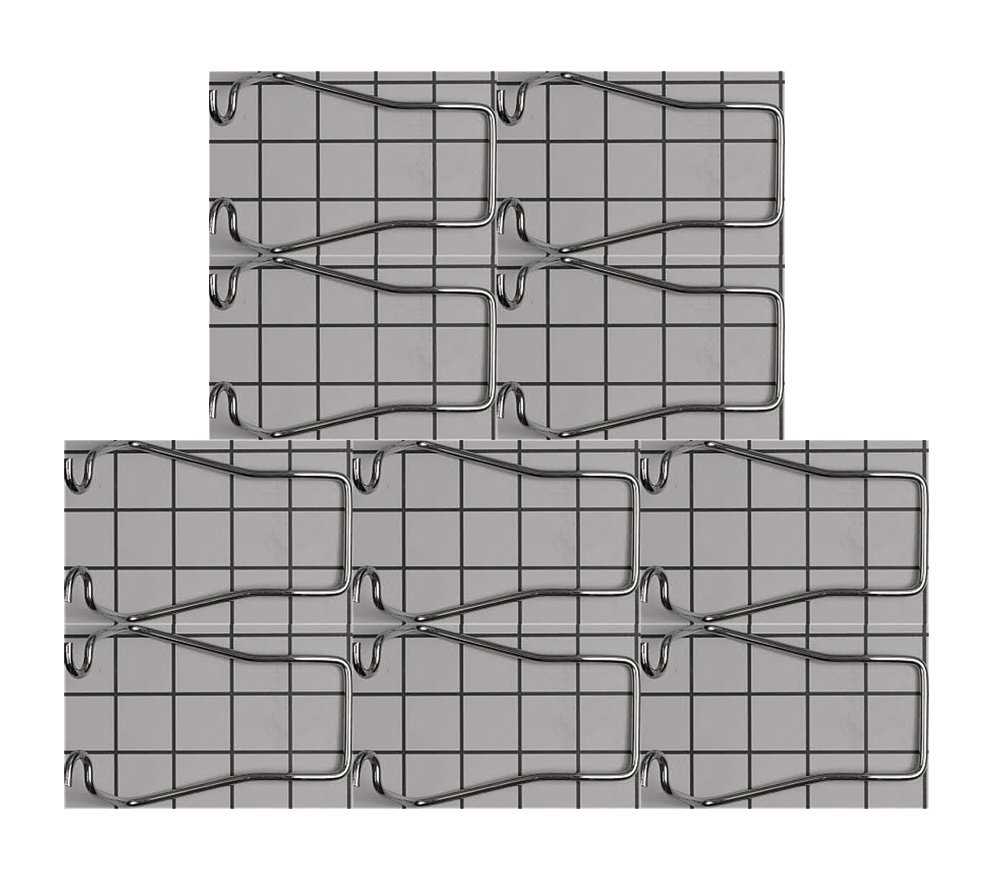

When working with maintenance documents, the first step is to familiarize yourself with the layout and labeling system used to represent the various elements of the machine. A well-structured visual guide can help you quickly pinpoint each component, making it easier to understand how they interact with one another. Knowing the identification methods ensures that you can navigate the guide with confidence, even if you’re not familiar with every part by name.

The key to effectively interpreting these illustrations lies in recognizing the symbols and number codes that correspond to each individual element. These guides often use clear markings, arrows, or labels to show the precise locations and connections. By following these visual cues, you can identify and locate specific pieces, whether for inspection, maintenance, or replacement purposes.

Once you understand how the system works, you’ll be able to efficiently troubleshoot any issues or perform necessary repairs. This knowledge allows you to cross-reference the components in the manual with the actual equipment, making the process much more manageable and accurate.

Common Issues and Replacement Tips

Over time, lawn tools may experience wear and tear that can affect their performance. Common issues often include reduced power, uneven cutting, or malfunctioning mechanisms. Identifying the source of these problems early on can save both time and money, allowing you to address the issue before it becomes more serious.

One frequent issue is a worn-out cutting blade or damaged wheel, which can result in poor functionality. If you notice the tool struggling or producing uneven results, it’s a good idea to check these components first. Replacing them with new, high-quality parts can restore performance and ensure a smoother operation.

Another common problem is the malfunction of the drive system or motor. If the equipment stops moving or lacks sufficient power, it may be a sign that internal gears or the power unit need attention. Regular maintenance, including cleaning and lubrication, can help extend the life of these parts, but when replacement is necessary, choose compatible and durable components for optimal performance.