When maintaining or repairing machinery, having a clear view of its internal structure is essential. Knowing where each component fits and how it interacts with others can greatly simplify the process. This guide offers a detailed look at the essential parts, allowing you to identify and address any issues effectively.

Comprehending the layout of key elements within a device is crucial for anyone involved in upkeep or troubleshooting. By breaking down the machine into its core sections, you can pinpoint problems faster and make informed decisions about replacements or repairs.

Understanding each component’s role will not only help you improve the functionality of your equipment but also extend its lifespan. This overview is designed to assist you in gaining confidence and efficiency when working with your machine’s internal mechanisms.

Understanding Key Components of Your Equipment

Every machine is made up of interconnected elements that work together to ensure smooth operation. Gaining a clear understanding of these individual components is vital for efficient maintenance and repair. Identifying each part’s specific function helps in troubleshooting and prevents unnecessary replacements.

Within any mechanical system, the core elements usually consist of the engine, transmission, control systems, and support structures. Understanding how each piece interacts with others provides insight into the overall performance and longevity of the device.

Familiarity with the key components makes it easier to detect faults early. Whether dealing with wear and tear, malfunctioning parts, or simple adjustments, recognizing the role of each section allows for quicker, more precise fixes, ultimately saving time and resources.

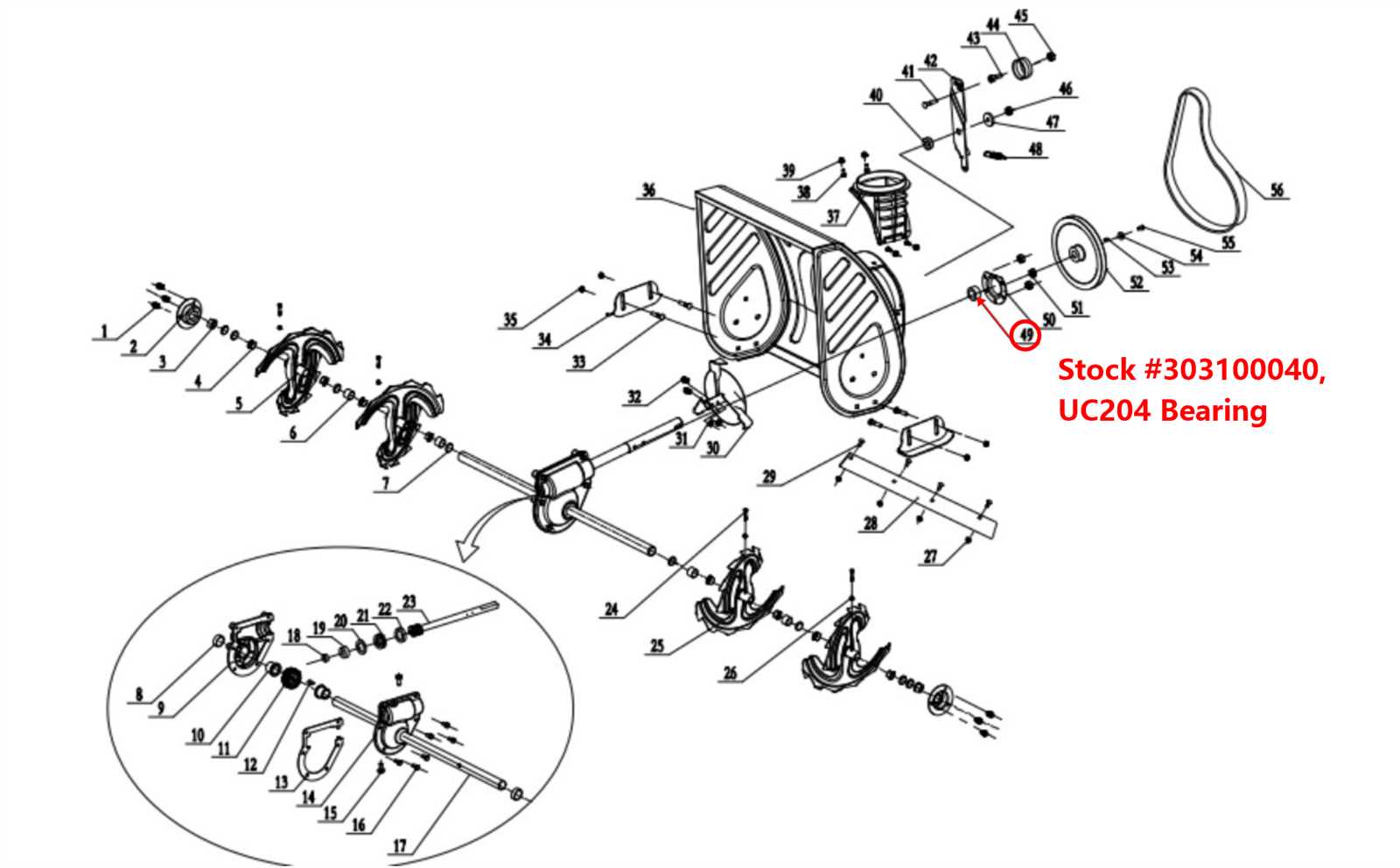

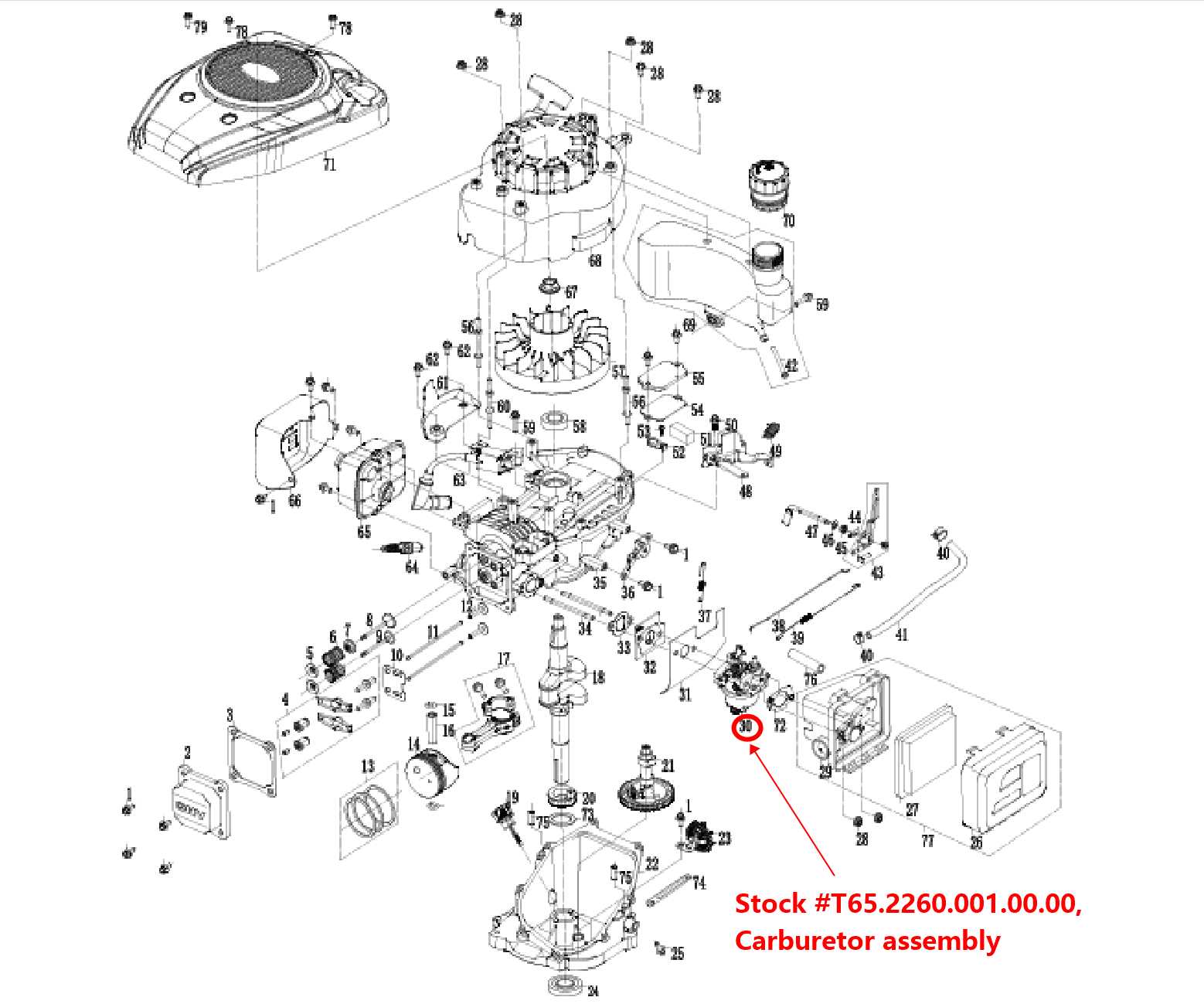

How to Read the Parts Layout

Understanding how to read a visual representation of your machine’s structure is crucial for effective maintenance. A detailed chart shows the arrangement of various elements, helping you identify each component and its position within the system. By studying these illustrations, you can gain insights into how the parts interact and how to handle replacements or repairs.

Key symbols and labels are typically used in such layouts to indicate each part’s name, number, and connections. Familiarizing yourself with these symbols allows you to navigate the chart more efficiently and find the exact components you need to focus on.

Pay attention to the numbering system and how different sections are grouped. This will help you understand the flow of the system and the importance of each element. Learning to interpret these details ensures that you can pinpoint issues accurately and make repairs with precision.

Common Issues and Replacements for Your Equipment

Machines, like any complex system, can encounter various issues over time due to wear, improper use, or external factors. Identifying the most common problems early on can save you from costly repairs and extend the life of your equipment. This section highlights frequent malfunctions and the best practices for resolving them with appropriate replacements.

Frequent Problems in Mechanical Systems

One of the most common issues faced by many devices is component wear, especially in moving parts such as motors or belts. Over time, friction can cause these parts to degrade, leading to poor performance or complete failure. Regular inspection can help catch such problems early, allowing you to replace parts before they cause more significant damage.

Recommended Replacements for Better Performance

When it comes to replacements, always choose high-quality components that match the specifications of your system. For instance, replacing a worn-out motor with a compatible, durable part can restore your equipment’s efficiency and functionality. Ensure that any replacement part is correctly installed and tested to avoid recurring issues.