Proper maintenance of cleaning machinery is crucial for ensuring its longevity and efficient performance. Understanding the internal components and how they function together can significantly enhance your ability to troubleshoot and repair issues as they arise.

Identifying key elements in your device will allow you to make informed decisions when it comes to maintenance and replacement. Familiarity with the assembly not only saves time but also helps in preventing potential malfunctions caused by overlooked details.

Whether you are a regular user or a technician, this guide will provide insights into the most common parts, their purpose, and solutions for frequent challenges. By exploring the setup and learning how each piece works, you will gain the confidence needed to address issues efficiently.

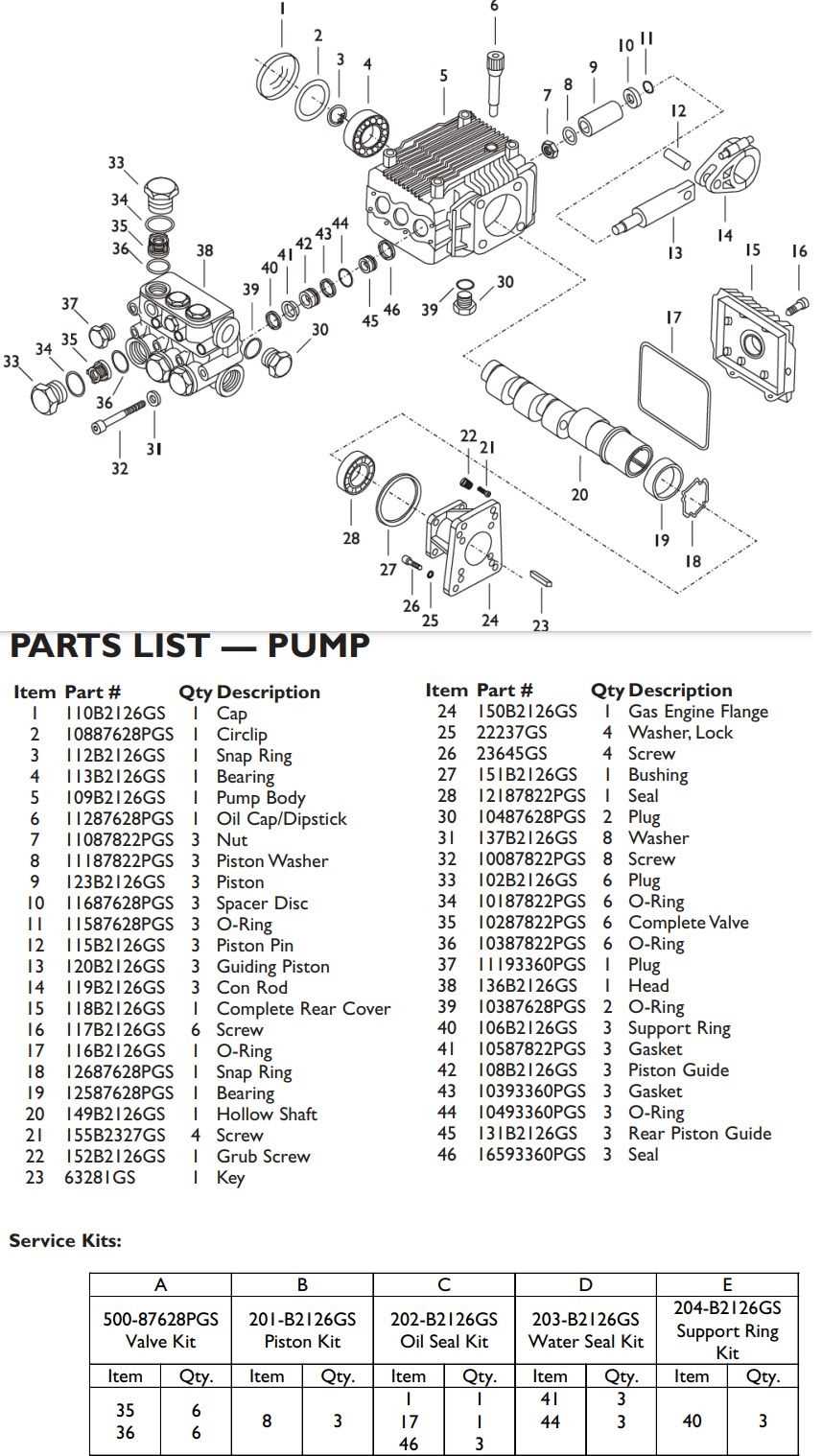

Understanding the Components of Your Power Washer

Knowing the main components of your cleaning device is essential for troubleshooting, repairs, and maintenance. These elements work together to create high-pressure cleaning, and understanding their roles can help you keep the system functioning optimally.

The engine or motor is at the core of the system, providing the necessary power. The pump transfers that energy into water pressure, which is directed through the nozzle. Additionally, the hose and other attachments are integral in directing water flow effectively for various cleaning tasks.

It’s also important to be familiar with the smaller, yet crucial, components such as valves, filters, and seals. These parts help regulate pressure and ensure smooth operation, preventing issues like leaks or inconsistent performance. Familiarizing yourself with these elements will enhance your ability to maintain the equipment and resolve issues promptly.

Step-by-Step Guide to Identifying Parts

Identifying the various components of your cleaning equipment is an important step in understanding how it works and performing effective maintenance. By breaking down the process, you can pinpoint the role of each element and make informed decisions when it comes to repairs or replacements.

Start with the core assembly of your machine, which typically includes the motor or engine. This central component powers the entire system, so understanding its function is critical. Once you locate the engine, follow the connections to other parts like the pump and valves.

Next, examine the flow system, which includes hoses, nozzles, and filters. These parts are responsible for directing the water and ensuring it reaches the intended surface. Inspect each of these components for wear and tear, paying attention to any damage that may affect performance.

Lastly, check the auxiliary elements such as seals, belts, and connectors. These smaller pieces help maintain optimal performance by preventing leaks, ensuring pressure regulation, and supporting smooth operation. By methodically identifying and understanding each part, you’ll be able to troubleshoot issues and enhance the efficiency of your equipment.

Common Issues and How to Fix Them

Like any mechanical equipment, cleaning devices are prone to common issues that can disrupt their performance. Identifying these problems early allows you to take proactive measures to fix them before they become more serious. Regular maintenance and quick troubleshooting can keep your machine running smoothly.

Loss of pressure is one of the most frequent issues users encounter. This can be caused by a clogged nozzle, a malfunctioning pump, or leaks in the hose. To resolve this, start by cleaning or replacing the nozzle, checking the hose for damage, and ensuring the pump is functioning correctly. If the pump is faulty, it may need to be replaced.

Water leakage can also occur due to damaged seals, connectors, or hoses. Inspect the components carefully to identify where the leak is coming from. In most cases, replacing worn-out seals or tightening connections will resolve the issue. If a hose is cracked, it should be replaced to prevent further damage.

Engine failure may result from fuel issues, faulty spark plugs, or internal blockages. Ensure the fuel is fresh, and check the spark plug for corrosion or wear. Cleaning or replacing the spark plug can help restore the engine’s performance. If there is an internal blockage, refer to the manual for guidance on clearing the obstruction.