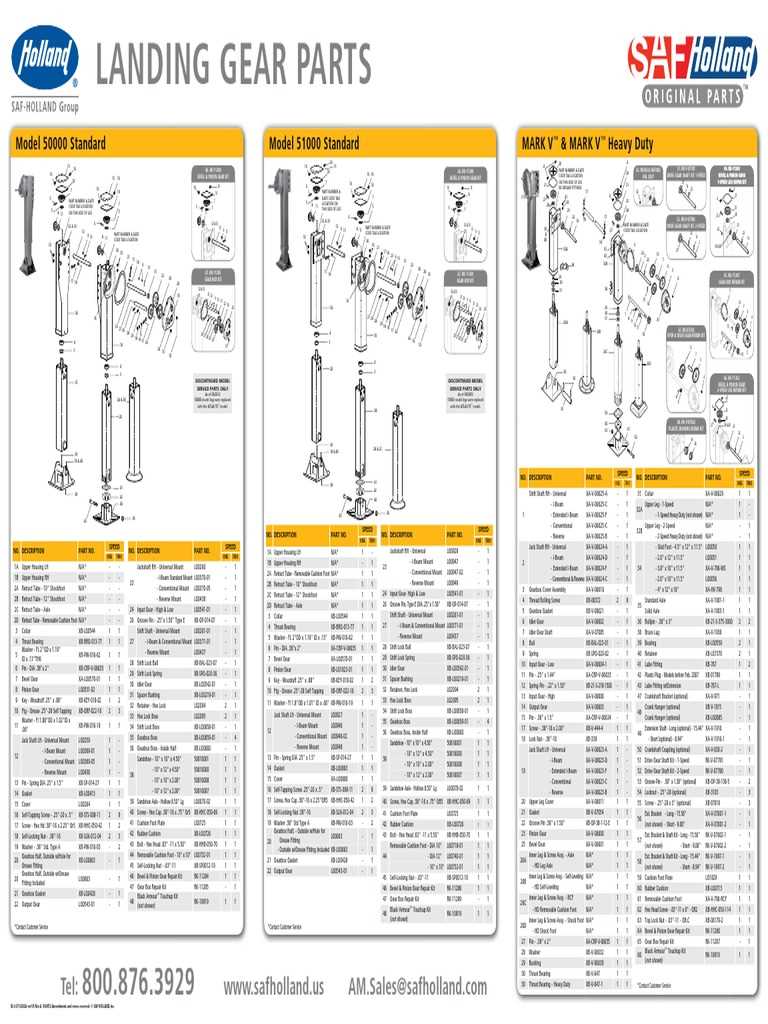

The functionality of a mobile unit’s support system is crucial for its stability and ease of use during parking or detachment. This system consists of several key elements that work together to provide strength and mobility. Recognizing the role of each element is essential for proper maintenance and troubleshooting.

Knowing the various components allows for more informed decisions when it comes to repairs and replacements. Each part plays a specific role in securing the unit in place while also making sure that adjustments can be made as needed. A comprehensive view of these elements ensures the safety and durability of the entire setup.

Detailed breakdowns of these components highlight their unique characteristics, providing insight into how they contribute to the overall performance. Whether for operational efficiency or long-term use, understanding this mechanism enhances your ability to keep the system in optimal condition.

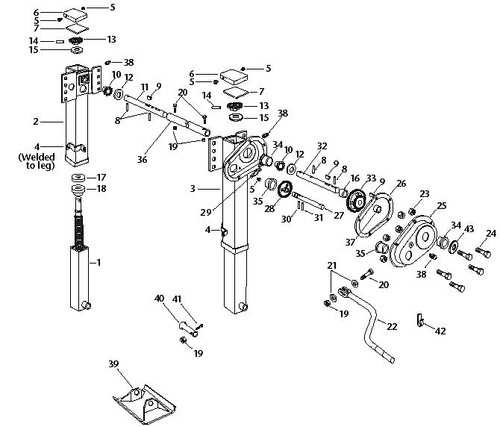

Key Components of a Support Mechanism

The proper functioning of a mobile unit’s stabilizing system relies on several essential elements working together to ensure support and ease of use. Each component serves a specific purpose, contributing to the overall performance and safety. Understanding these parts is vital for both maintenance and troubleshooting to keep the system in good working condition.

One critical element is the primary stabilizer that allows for vertical adjustment, providing stability when the unit is not in motion. This element must be strong and durable, as it carries a significant amount of weight and undergoes frequent adjustments. Another important component is the rotating mechanism, which allows for smooth movement and repositioning. This part ensures that the support system can be adjusted without excessive force or difficulty.

Supporting structures also include locking systems that prevent unintended movement. These are essential for maintaining the desired position once the adjustments have been made. Additionally, wheels or rollers are often incorporated to facilitate easy repositioning when needed, offering both flexibility and functionality. All these elements come together to form a comprehensive system designed for efficient use and long-lasting durability.

How to Identify Support System Components

Recognizing the various elements of a stabilizing mechanism is essential for proper maintenance and repair. Identifying these components can be challenging without the right knowledge, but understanding their function and appearance makes the process more straightforward. A clear grasp of each part’s role will help in diagnosing issues and selecting the correct replacements when necessary.

Recognizing the Primary Stabilizer

The main support structure is usually the most prominent part of the system, designed to bear significant weight and provide vertical adjustment. This component is typically large and built from heavy-duty materials for durability. Look for a cylindrical shape with mechanisms for raising or lowering the system. Pay attention to any visible locking mechanisms that hold the unit in place when in use.

Identifying Secondary Elements

Secondary components often include the rotating or swiveling mechanisms, which allow for smooth movement of the system. These elements may feature gears or wheels for mobility. Additionally, check for smaller structures that provide support during repositioning, such as wheels or rollers. These parts often have a distinct appearance, with rotating features or casters designed for easy movement.

Common Issues with Support Mechanisms

Like any mechanical system, the stabilizing structure of a mobile unit can experience wear and tear over time. Recognizing the common issues that arise can help address problems early, preventing costly repairs and ensuring optimal performance. From mechanical malfunctions to wear-related failures, several factors can hinder the system’s effectiveness.

Sticking or Jammed Adjustments

One of the most frequent issues involves difficulty in adjusting the height or position of the support system. This can occur when the internal mechanism becomes clogged with debris, rust, or dirt. In such cases, the system may be difficult to raise or lower, requiring excessive force. Regular cleaning and lubrication can often solve this problem and restore smooth functionality.

Worn or Broken Wheels

The wheels or casters used for repositioning the unit can wear down over time, especially when exposed to heavy loads or rough surfaces. When these components become damaged or worn, they may fail to roll properly, making it difficult to move the unit. Replacing the wheels or casters with high-quality replacements is essential to maintain mobility.