When it comes to maintaining heavy-duty agricultural machinery, having a clear visual guide can make all the difference. Recognizing the individual components and knowing their functions is essential for efficient repairs and optimal performance. A well-detailed schematic can help users avoid mistakes and save time when handling equipment issues.

Such guides typically break down complex machines into easily identifiable sections, providing clear depictions of each critical element. Whether you are a seasoned operator or new to the task, understanding how each part fits together and operates is crucial for ensuring smooth maintenance processes.

Using these resources properly allows for better troubleshooting, parts replacement, and routine upkeep. With the right reference material, you can approach repairs with confidence and ensure your equipment remains in top condition for long-term use.

Understanding Agricultural Machinery Components

In any complex piece of agricultural machinery, each element plays a vital role in ensuring smooth operation and efficiency. Recognizing the various components and their specific functions is key to proper maintenance and troubleshooting. Whether it’s the cutting system, the drive mechanism, or the structural framework, understanding how these elements interact is essential for any operator.

The machinery in question typically consists of several core sections, each designed to perform a distinct function. From the power source that drives the entire system to the blades that handle the physical work, every part has a specific purpose that contributes to the overall performance. Understanding these components and their relationship with one another helps prevent common mechanical failures and allows for quicker repairs when needed.

Familiarity with the internal and external features of the equipment also aids in recognizing potential issues before they escalate. With the right knowledge, operators can efficiently diagnose problems and replace faulty elements, extending the life of the machinery and ensuring reliable performance throughout its use.

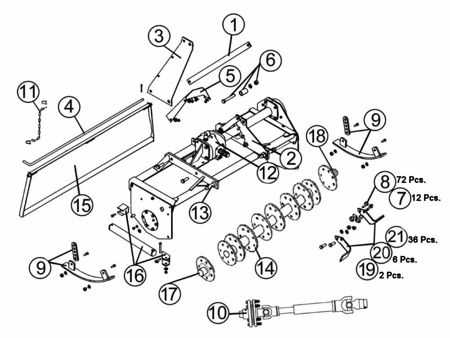

How to Identify Key Agricultural Equipment Components

When working with large machinery, it is crucial to know how to identify the main elements that make up the system. This knowledge allows for better maintenance and timely repairs. Each essential component serves a unique purpose, and understanding its function is the first step toward ensuring the longevity and efficiency of the equipment.

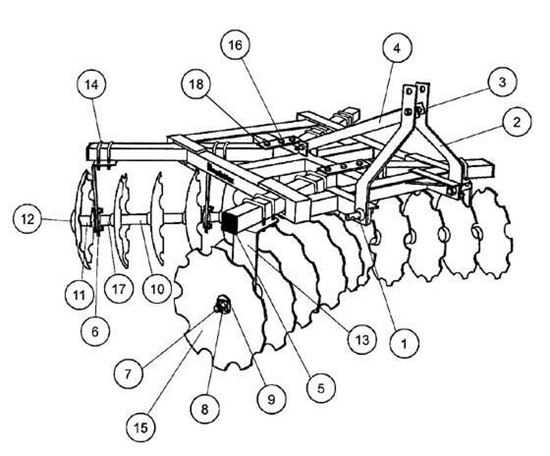

Recognizing the Power Transmission System

The power transmission system is one of the most important sections of any heavy-duty machine. It consists of the driveshaft, pulleys, and belts, all working together to transfer power from the engine to the cutting mechanism. Being able to identify issues within this system, such as worn-out belts or damaged pulleys, is essential for avoiding performance problems.

Understanding the Cutting Mechanism

The cutting mechanism is another critical component that directly affects the efficiency of the machine. This system includes the blades, gear assemblies, and supporting structures that facilitate the actual cutting process. Proper identification of these parts helps in detecting wear and tear, ensuring that all components are sharp and intact for optimal performance.

Steps for Using the Components Guide Effectively

Utilizing a schematic for machinery maintenance can greatly simplify the repair process. By carefully following the layout, users can identify each critical element and understand how they fit into the overall system. This not only helps in troubleshooting but also in ensuring that all components are replaced correctly when necessary.

Start by Familiarizing Yourself with the Layout

Before diving into the specifics of individual components, take a moment to study the entire layout. The schematic often divides the machinery into different sections, making it easier to locate the part you’re working on. Understanding the organization of the guide will help you navigate through the document more quickly, saving you time during the repair process.

Cross-Reference with the Physical Equipment

Once you’ve identified the parts in the schematic, physically inspect the machinery to match the components. This step is essential to ensure you’re looking at the correct elements and to avoid confusion, especially when dealing with similar-looking parts. Cross-referencing helps confirm that you’re addressing the right issue and can prevent mistakes that could damage the equipment.