For effective maintenance and repairs, understanding the inner workings of your equipment is essential. Identifying the different elements and their functions ensures optimal performance and longevity. In this guide, we will break down the key components of a powerful handheld blower, providing you with the necessary tools to diagnose and replace parts when needed.

Accurate identification of individual parts is critical to troubleshooting any issues. Knowing where each component fits into the system will help prevent common mistakes and reduce the chances of improper repairs. Whether you’re looking to replace worn-out pieces or performing routine checks, this resource will serve as a helpful reference.

Once you’re familiar with the various parts, the next step is ensuring their proper installation and maintenance. Proper care of each element can prolong the life of your equipment and avoid unnecessary downtime. We’ll guide you through each step, making your repair process straightforward and hassle-free.

Understanding the Blower Components

Every powerful blower is made up of several critical components that work together to ensure smooth operation. Each part plays a specific role in the overall functionality of the equipment, and understanding these elements is key to maintaining optimal performance. From the engine to the nozzle, each piece needs to be in good condition for the blower to operate efficiently.

Engine – The heart of the machine, converting fuel into power. A well-maintained engine ensures consistent performance and minimizes breakdowns during heavy use.

Air Intake System – This part allows the flow of air into the engine, which is crucial for combustion. Blockages or damage here can lead to overheating or reduced power output.

Fan – Responsible for creating airflow, the fan forces air through the system. Its condition directly impacts the strength and direction of the airflow, making it vital for effective operation.

Nozzle – The part through which air is directed toward the target. The size and shape of the nozzle affect the control and precision of airflow, making it an important feature for various tasks.

Each of these components interacts to ensure your blower works as efficiently as possible. Regular inspection and replacement of worn-out pieces can keep your equipment performing at its best, reducing the likelihood of costly repairs in the future.

How to Identify Blower Components

Accurately identifying the various elements of your blower is crucial for effective maintenance and repair. Each component has a specific function, and recognizing these parts can save you time and effort when troubleshooting or replacing faulty pieces. Whether you’re dealing with an engine issue or airflow problems, knowing how to pinpoint the correct components is the first step toward a successful fix.

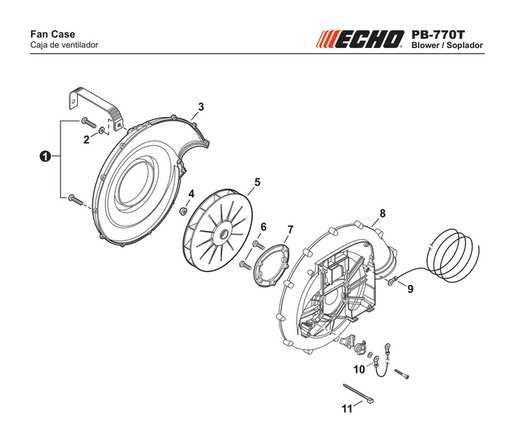

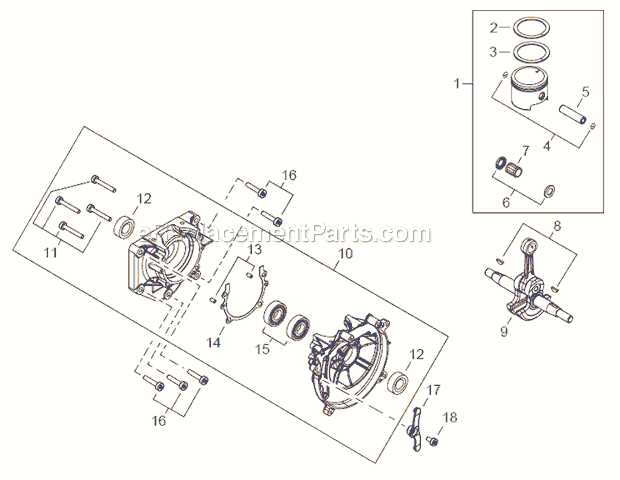

Start by consulting the user manual, which typically includes detailed illustrations or labels to help you identify each section of the machine. These diagrams provide a clear visual representation of where each part fits and its relationship to other elements.

Next, carefully examine the blower’s exterior, looking for labels or part numbers. Manufacturers often stamp important information directly onto the body or its components. These numbers can help you match the right piece with the correct replacement.

Finally, understand the function of each part by observing its role in operation. For example, if the blower is not producing adequate airflow, the issue may lie with the fan or nozzle. Identifying the malfunctioning part based on the performance of the equipment can guide you in making the right repairs.

Step-by-Step Guide for Replacing Blower Components

Replacing faulty components in your blower is a straightforward process if done correctly. Properly following each step ensures that your equipment runs efficiently after repairs. This guide will walk you through the process of replacing worn or damaged parts, helping you avoid common mistakes and achieve lasting results.

First, ensure the blower is powered off and disconnected from any fuel sources. Safety should always be your top priority when working with machinery. Gather the necessary tools, such as a screwdriver, wrench, and replacement parts, before beginning the process.

Next, carefully remove any covers or shields that protect the internal components. Most blowers have accessible screws or latches that need to be undone to expose the parts that require attention. Pay attention to how each cover is removed, as you’ll need to reattach them in the same manner later.

Once the cover is removed, locate the component that needs replacing. If you’re unsure, refer to the manual or part numbers to help guide your search. For example, if the fan is damaged, you may need to remove it from its housing. Use the appropriate tool to unscrew or unclip the component carefully.

After removing the old part, install the new one, ensuring it fits securely. Double-check that all connections are tight and that the component is correctly aligned. Once installed, replace the cover and any other components you removed earlier.

Finally, test the equipment to ensure it functions properly. If the blower starts without issues and operates smoothly, you’ve successfully replaced the component. Regularly checking your equipment for wear and replacing faulty parts will keep it in top working condition for years to come.