Every machine consists of various interconnected elements that work together to ensure its optimal performance. Familiarizing yourself with these components is essential for efficient maintenance and repair. By understanding how each part functions within the system, you can easily identify issues and perform necessary adjustments.

In this section, we will explore the key parts of the device, focusing on their arrangement and how they contribute to the overall operation. Whether you’re troubleshooting or looking to replace specific pieces, having a clear understanding of the layout can greatly enhance your experience.

Maintenance and repairs become significantly easier when you know where each part is located and how it interacts with others. With the right knowledge, you can handle repairs with confidence and extend the lifespan of your equipment.

Understanding the Key Components

Every tool or equipment is built with a variety of essential elements that contribute to its performance. By familiarizing yourself with the different components, you can gain a deeper understanding of how each part functions and how they work together as a system. This knowledge is crucial when it comes to troubleshooting, repairs, or even routine maintenance.

Core Elements of the Machine

At the heart of any equipment are the major components that enable it to operate efficiently. These include the motor, air filter, fuel system, and exhaust. Each part plays a specific role, and their proper functioning ensures that the tool runs smoothly. A malfunction in one of these elements can affect the entire system, making it important to monitor their condition regularly.

Smaller Parts and Their Roles

In addition to the core components, there are smaller, yet equally important, pieces that support the operation of the machine. These elements include fasteners, seals, and various attachments that assist in the overall structure and usability of the device. Understanding how each of these parts interacts will help in performing more accurate repairs and adjustments.

How to Read the Components Layout

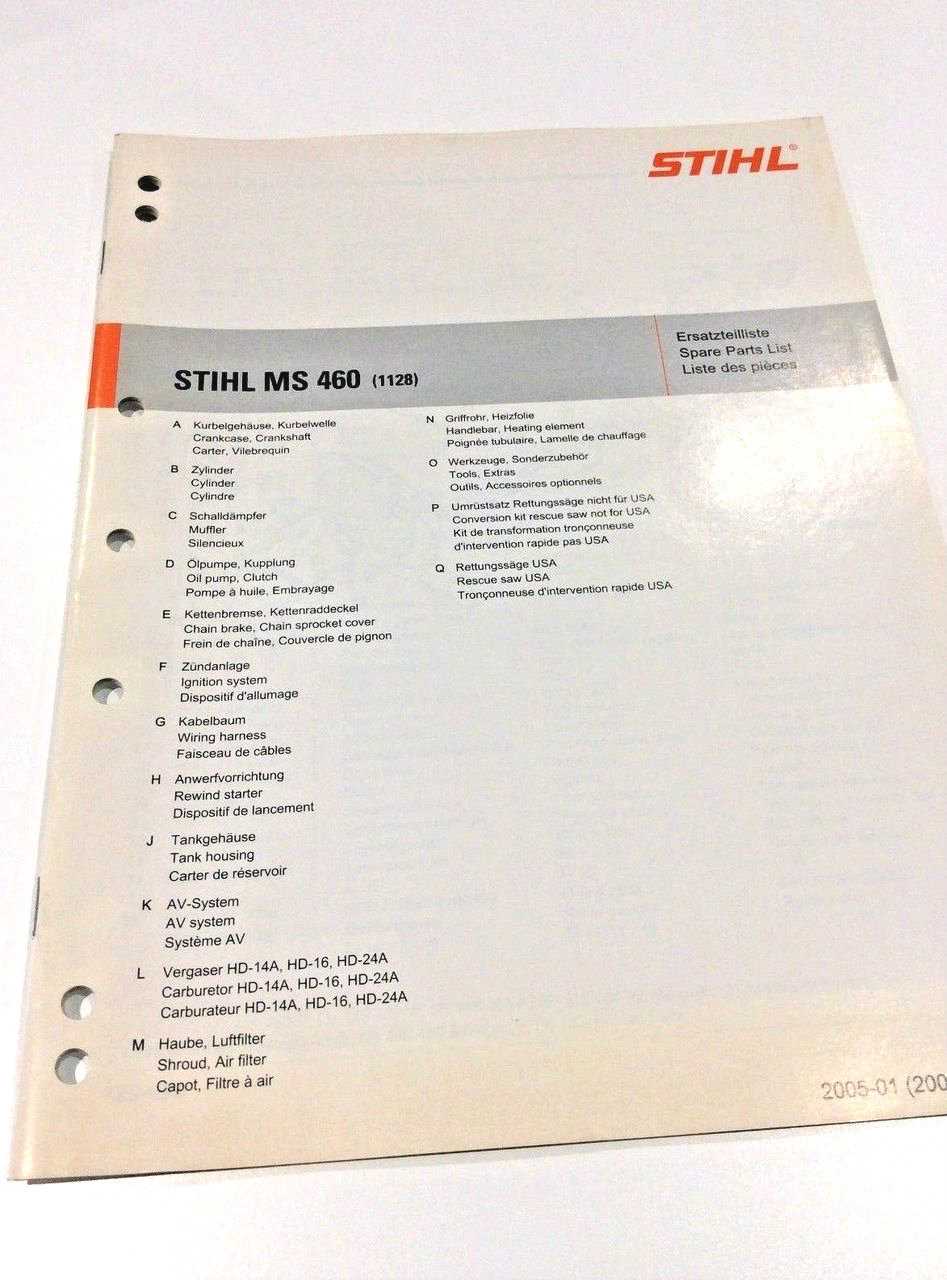

Understanding how to read a layout showing the various elements of your equipment is an essential skill. These illustrations are designed to provide a visual representation of the structure and arrangement of each part, helping users identify where each piece fits and how they work together. By interpreting these visuals correctly, you can easily locate components for maintenance, repair, or replacement.

Decoding the Labels and Symbols

Each part in the visual guide is labeled with a unique reference number, which corresponds to a list or catalog of parts. These numbers are used to identify and locate the specific components needed for repair or replacement. In addition to the reference numbers, certain symbols or markings may be included to indicate the type of material, orientation, or specific installation instructions for each element.

Understanding the Layout Structure

Most layouts are organized to show the components in a way that mirrors the assembly of the machine. Major parts will be shown first, with smaller supporting elements placed around them. The layout may also highlight certain parts that are commonly replaced or subject to wear and tear. By following the logical flow of the diagram, you can easily navigate the equipment and identify the correct part you need.

Common Issues and Part Replacements

Over time, all equipment experiences wear and tear, leading to potential malfunctions. Recognizing common problems early and knowing which components need replacing can save time and prevent further damage. Understanding the most frequently replaced elements will help you maintain the machine’s performance and extend its lifespan.

One of the most common issues is a malfunctioning fuel system, which may lead to poor engine performance. In such cases, the fuel filter or fuel lines may need to be replaced. Similarly, if the air intake is clogged or damaged, replacing the air filter will restore efficiency and ensure smooth operation.

Another frequent concern is the deterioration of seals and gaskets, which can lead to leaks and affect the overall functionality. Regular inspection of these parts is essential, as they are often subject to wear and require replacement at intervals to prevent further damage to the equipment.