Understanding how household machines function is crucial for effective maintenance and repair. By becoming familiar with the individual elements that make up these devices, owners can troubleshoot common issues with ease. This guide provides a closer look at the internal components that are essential to the proper operation of your appliance.

From identifying malfunctioning parts to understanding their role within the system, knowing the layout and connection of key components can save both time and money. Whether you’re attempting a DIY fix or simply trying to recognize a problem, this knowledge empowers you to handle situations confidently.

In the following sections, we will break down the most common elements, their functions, and how to access and replace them. With this information, you’ll be able to assess and resolve issues with a clear understanding of the underlying mechanisms at play.

Understanding Whirlpool Dryer Components

Every appliance relies on a complex network of components working together to ensure optimal functionality. Recognizing how each part contributes to the overall operation is key to identifying and addressing any issues that may arise. These systems are designed to be efficient, but understanding their layout and role can significantly reduce troubleshooting time.

The main components of a machine, such as motors, belts, and sensors, work in unison to carry out specific tasks, from generating heat to controlling airflow. If one element fails, it can affect the entire process, making it essential to understand where each piece fits into the larger system. By gaining insight into the internal structure, you are better equipped to diagnose problems and prevent potential breakdowns.

In this section, we will explore the most essential components that you’ll encounter, detailing their purpose and how they interact with each other. This knowledge is valuable not only for resolving immediate issues but also for extending the life of the appliance through informed maintenance and care.

Common Issues and Part Locations

When a machine malfunctions, it’s often the result of one or more components failing to perform their specific function. Identifying the source of the issue is the first step in resolving it, and understanding where each part is located can make the diagnostic process much easier. Knowing the common failure points and their corresponding locations helps you take immediate action to restore functionality.

Several parts are more prone to wear and tear over time. These include the heating element, belt, motor, and sensors. In this section, we will highlight the most frequent issues that arise with these components and where to find them inside the system.

| Issue | Common Location |

|---|---|

| Not Heating | Heating Element, Thermal Fuse |

| Excessive Noise | Drive Motor, Belt |

| Won’t Start | Start Switch, Motor, Belt |

| Clothes Not Drying | Airflow Vents, Lint Filter |

| Power Issues | Power Cord, Fuse |

By identifying these common issues and knowing where to find the corresponding components, troubleshooting and repairs become a much more straightforward task. Regular inspections of these key areas can also help prevent future breakdowns and ensure continued efficiency in the machine’s operation.

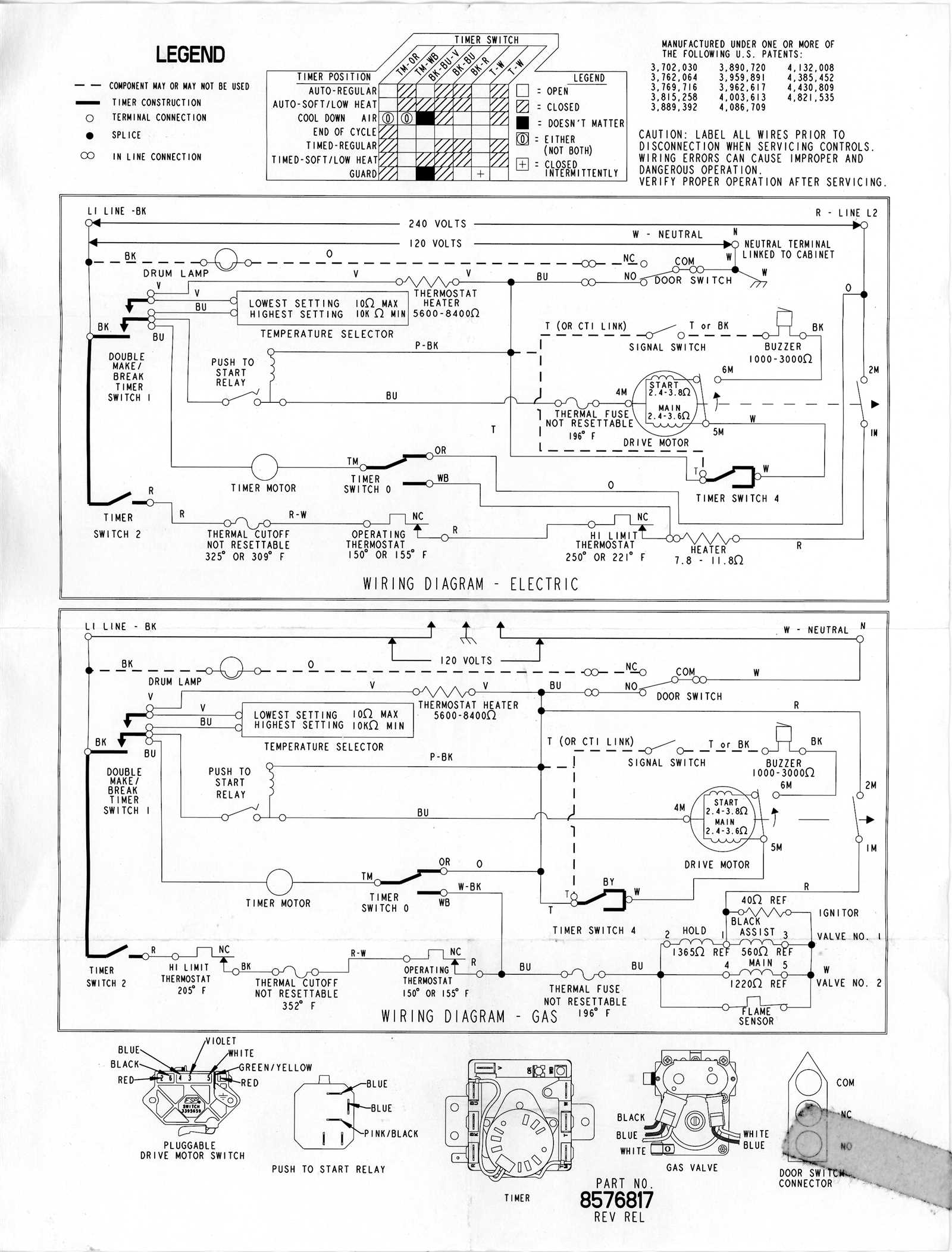

How to Read Whirlpool Dryer Diagrams

Understanding the layout of a machine’s internal system is essential for efficient troubleshooting and repair. Diagrams offer a visual representation of how components are connected, helping you identify issues quickly. Learning how to read these layouts allows you to pinpoint problems without needing to physically inspect each part, saving time and effort.

Key Elements to Look For

When examining a schematic or layout, there are several key aspects to pay attention to:

- Component Identification: Each part is labeled with a unique reference number or letter. Make sure you can match these identifiers with the parts in your device.

- Connections: Lines or arrows indicate how components are interconnected. Understanding these connections will help you see how a malfunction in one part can affect others.

- Power Flow: Some diagrams show how power travels through the system, which is crucial when diagnosing electrical issues.

Interpreting the Diagram

Once you have identified the key components and their connections, follow these steps to interpret the diagram effectively:

- Locate the part that you suspect is malfunctioning. This may require some knowledge of typical issues, such as overheating or motor failure.

- Trace the connections to determine if the malfunction is linked to other parts. For example, if the heating element is faulty, it may be related to the thermostat or thermal fuse.

- Check the power flow. If certain components aren’t receiving power, the issue could be in the wiring or the power source.

- Use the reference numbers to cross-check parts in the layout against the actual components in your device for accurate replacement.

By carefully reading and analyzing these visual representations, you gain a clearer understanding of the system, which improves both diagnostic accuracy and repair efficiency.

Step-by-Step Guide to Troubleshooting

When an appliance stops working as expected, it’s important to follow a systematic approach to identify and resolve the issue. A step-by-step troubleshooting process helps you isolate the problem, making it easier to address without unnecessary guesswork. This guide outlines the necessary steps to efficiently diagnose and fix common issues.

Begin by ensuring the machine is properly connected to a power source. Sometimes, the simplest solution is to check if the device is receiving power or if there is an issue with the outlet or power cord. Once confirmed, move on to inspecting specific components and their functions.

- Check the Power Supply: Verify that the appliance is properly plugged in and the power switch is turned on. Inspect the power cord for any visible damage.

- Inspect Safety Features: Look for any blown fuses, tripped circuit breakers, or faulty thermal cutoffs. These components are designed to protect the machine from overheating or electrical overload.

- Examine Internal Components: Open the access panel and inspect the main parts such as the motor, belts, and sensors. Look for any signs of wear or damage that could be causing malfunctions.

- Test the Heating Element: If there’s no heat, the heating element or related components like the thermal fuse might be at fault. Use a multimeter to check for continuity and replace faulty parts as needed.

- Check the Ventilation System: Blocked vents or filters can lead to overheating or poor performance. Make sure airflow is unobstructed and clean any lint or debris from the exhaust system.

- Run a Cycle Test: After inspecting and replacing damaged parts, run a test cycle to confirm that the appliance is operating as it should. Listen for unusual sounds or signs of further issues.

By following these steps methodically, you can effectively diagnose and resolve most common issues. Regular maintenance and timely repairs will keep your appliance functioning smoothly for longer periods.

Essential Whirlpool Dryer Parts for Repair

When tackling appliance repairs, it’s crucial to understand which components are most often involved in common malfunctions. Some parts are more susceptible to wear and tear, while others play critical roles in the overall function of the machine. Knowing which components are essential and where to find them can make the repair process much smoother.

The key elements that often need replacement or maintenance include the heating element, drive motor, belt, thermal fuse, and sensors. These components are responsible for various functions, from generating heat to maintaining proper airflow, and they tend to experience the most strain during regular use.

Heating Element: This part is responsible for generating the heat required for drying clothes. If it fails, the appliance will not produce heat, making the drying process ineffective.

Drive Motor: The drive motor powers the drum, allowing it to rotate during the drying cycle. A malfunctioning motor can result in the drum not spinning, causing clothes to remain wet or damp.

Belt: The belt is a crucial part that connects the motor to the drum. If the belt breaks or slips, the drum will not rotate properly, preventing the machine from functioning correctly.

Thermal Fuse: This safety feature cuts off power to the appliance if it overheats, preventing potential fire hazards. A blown thermal fuse often results in the appliance failing to start or run.

Sensors: Temperature and moisture sensors monitor the internal environment, ensuring the machine dries clothes effectively without overheating. If these sensors malfunction, they may cause overheating or inadequate drying.

Familiarity with these essential components can help you identify issues more quickly, allowing for efficient repairs. Having spare parts on hand for these common failures ensures that your appliance remains functional and safe to use for a long time.