When it comes to maintaining outdoor power equipment, understanding the internal mechanisms is crucial. Whether you’re a seasoned mechanic or a homeowner handling DIY repairs, knowing how the different components work together is essential for optimal performance.

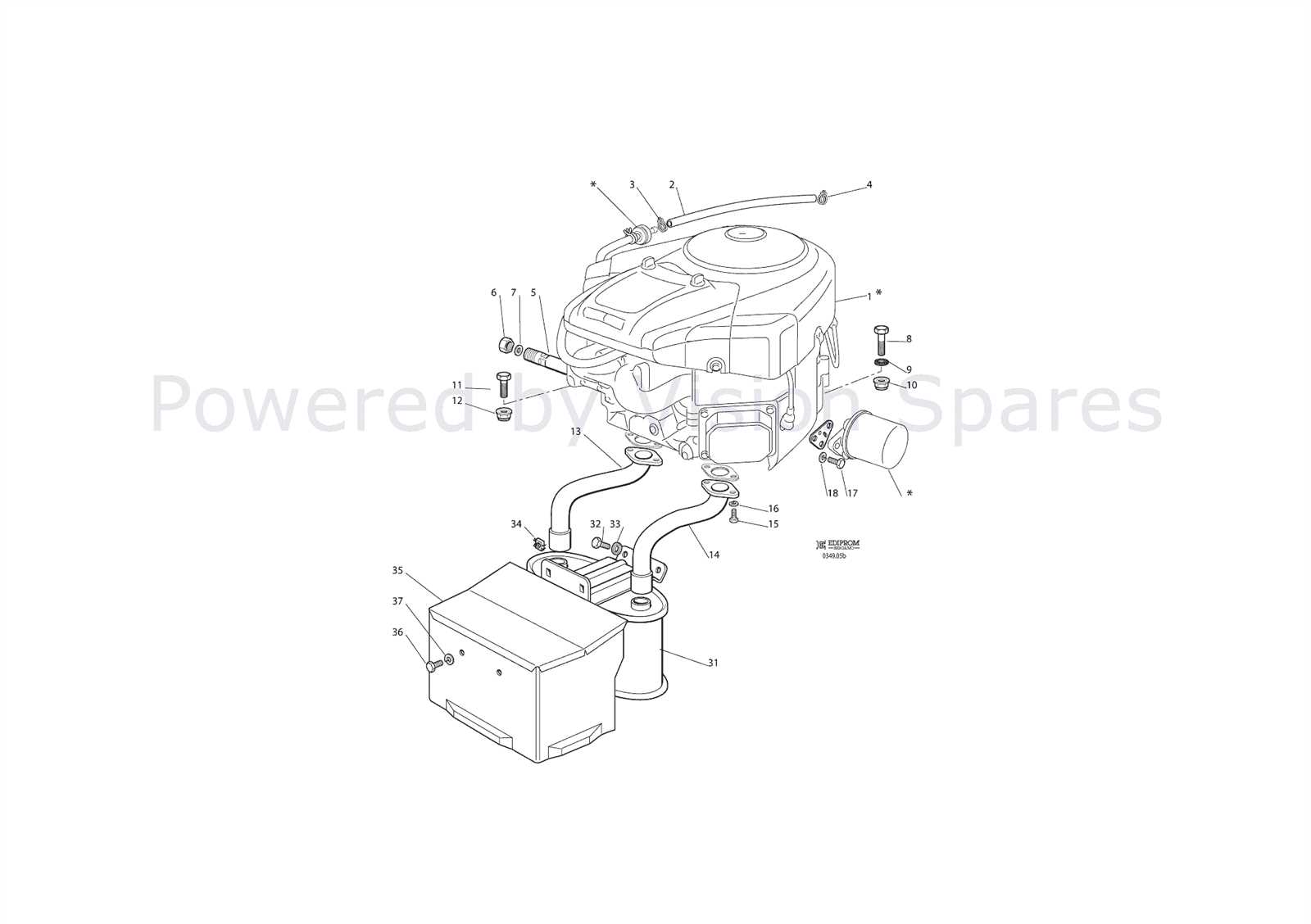

Learning to identify each element of your small machinery can make troubleshooting easier and more efficient. Visual references, such as detailed schematics, provide a clear view of how all the components fit into the overall structure, ensuring you can pinpoint issues quickly and effectively.

Proper care of individual components helps extend the life of your equipment. Knowing the right procedure for inspecting, cleaning, or replacing specific parts ensures long-term reliability and reduces the chances of unexpected breakdowns.

Understanding Small Engine Components

To ensure the smooth operation of any machinery, it’s important to comprehend how each component functions and interacts with the rest. Familiarizing yourself with the core elements of a small power unit can help in diagnosing issues, performing regular maintenance, and making replacements as necessary. This knowledge enables owners to keep their equipment running at peak efficiency.

Key Elements to Focus On

Major components in small power systems include the fuel delivery system, ignition mechanisms, air intake, and cooling structure. These elements work together to provide the necessary power and control, each performing specific functions that contribute to the overall performance. Understanding how these parts are organized and maintained can prevent unnecessary wear and tear.

Why Component Awareness is Important

Recognizing the role each part plays allows for more informed decisions when it comes to troubleshooting or replacing faulty components. Even routine upkeep like changing filters, cleaning fuel lines, or checking spark plugs becomes easier when you understand the structure of your machine. Proper care ensures reliability and can extend the lifespan of your equipment significantly.

Key Parts in Your Machine Layout

Every mechanical system consists of several critical components that work in unison to generate power and facilitate operation. By identifying these key elements, you can better understand how they interact and why they are essential for smooth function. Knowing their location and role in the assembly can help with troubleshooting, repair, and routine maintenance.

Essential Elements for Operation

Among the most vital components are the fuel system, ignition system, and air intake system. These elements are responsible for delivering the energy required to power the unit, ignite the fuel mixture, and ensure proper airflow. Their efficient performance directly affects the overall operation, making regular inspection of these systems crucial to maintaining reliability.

System Interaction and Maintenance

While each part serves a unique purpose, the way they interact within the entire structure is equally important. Regular checks and maintenance of these components ensure the engine runs smoothly and can prevent unnecessary breakdowns. Understanding how each system contributes to the overall function helps you spot potential issues early and make informed decisions on repairs or replacements.

How to Read Engine Parts Diagrams Effectively

Interpreting a visual layout of a mechanical system is an essential skill for any technician or DIY enthusiast. These schematics offer a comprehensive view of how each component fits together, making it easier to identify specific elements and understand their functions. By mastering how to read these illustrations, you can streamline maintenance tasks and improve repair accuracy.

To read these visual guides effectively, follow these steps:

- Identify the Key Areas: Start by locating the most important sections of the layout, such as the power delivery system, ignition, or cooling mechanisms. These areas are usually highlighted or positioned centrally for easy reference.

- Understand the Symbols: Familiarize yourself with common symbols used in the diagram to represent different parts, such as bolts, gears, or seals. Knowing these will help you quickly decipher the information provided.

- Follow the Flow: Pay attention to how the components are connected and how the power flows from one part to another. This can give you valuable insight into potential issues and the order of assembly.

- Cross-reference with the Manual: If the diagram is unclear, cross-check it with the user manual or specific part lists. These resources often provide more detailed explanations for each part’s function.

By following these tips, you’ll be able to read mechanical schematics with confidence and use them to address any issues that may arise. The more familiar you become with the layout, the more efficient your repair and maintenance tasks will be.